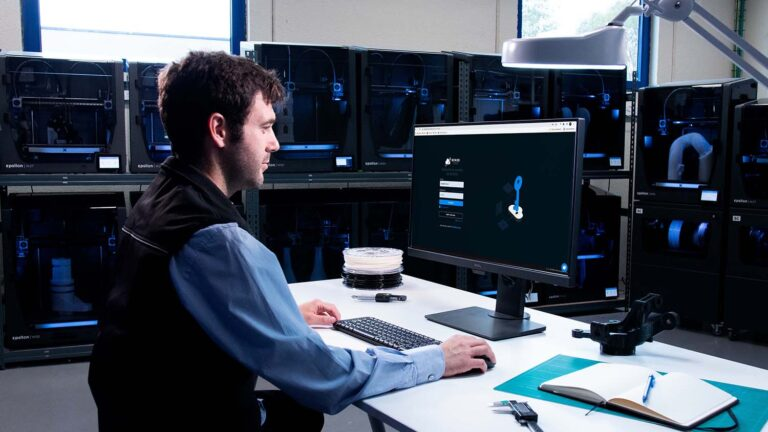

BCN3D Cloud Released for Real-time 3D Printing Fleet Management

BCN3D released a complete reinvigoration of their current BCN3D Cloud platform. The new web-based cloud will allow companies to scale up their additive manufacturing operations and make entire printing workflows more efficient, controlled, and easier than ever before.