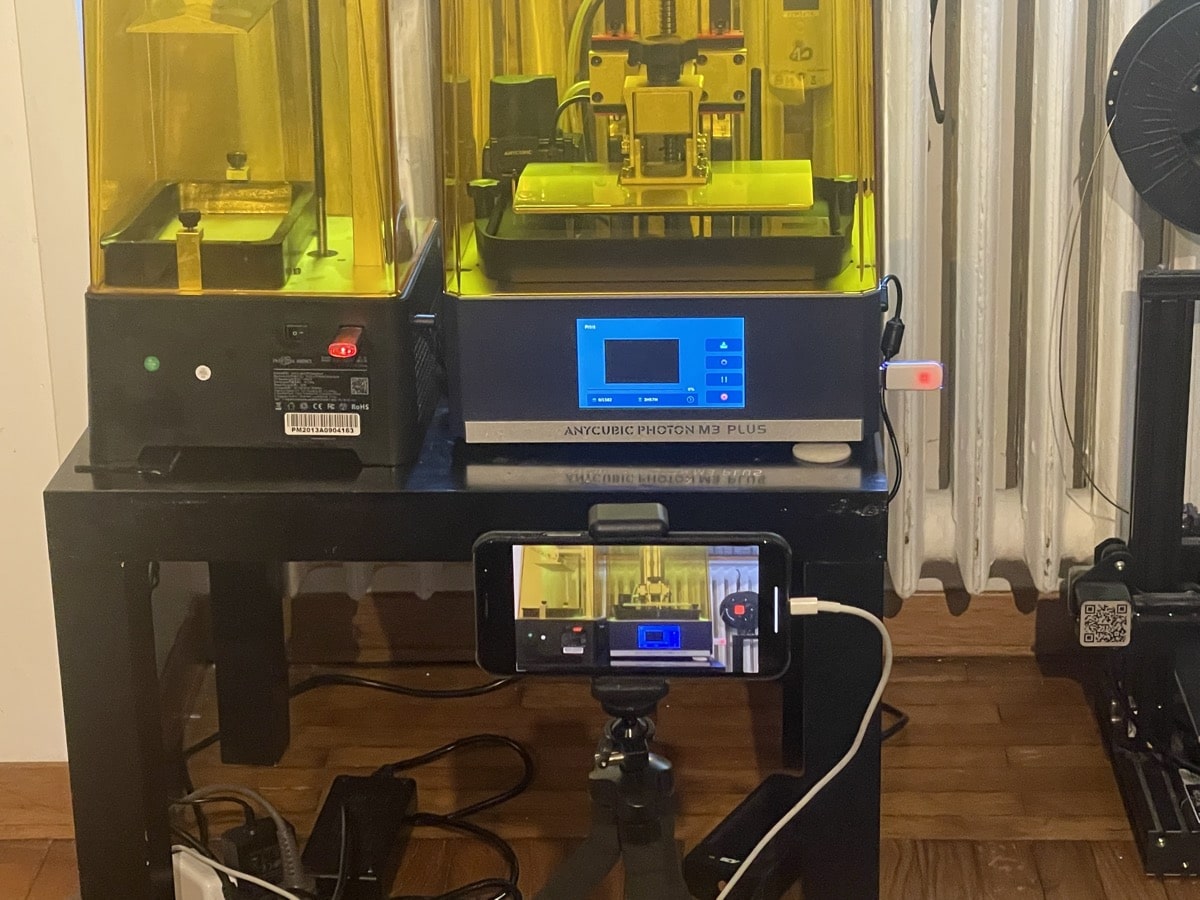

Scale Your LCD 3D Printing with the Anycubic Photon M3 Plus

Over the past few months, we have been able (thanks to the very efficient marketing and partnerships team at Anycubic) to test several Anycubic systems, for both filament extrusion and photopolymerization technologies. While we have not had the opportunity to compare them with many other similarly priced systems, we sometimes feel we don’t need to. Every Anycubic system we’ve tried so far has far exceeded our expectations and they just keep getting better. The latest one that we had the opportunity to test is the new Anycubic Photon M3 Plus, which was released last March, together with the M3 and M3 Max (and with the filament extrusion systems Kobra and Kobra Max). It has been a very, very fun and positive experience, to the point that we now think that the M3 Plus’ competitors are not other similarly priced systems but even the much more expensive systems.