3D Printed Tire Molds by SLM Solutions Used to Manufacture Next Gen Tire Threads 3D Printer Hardware

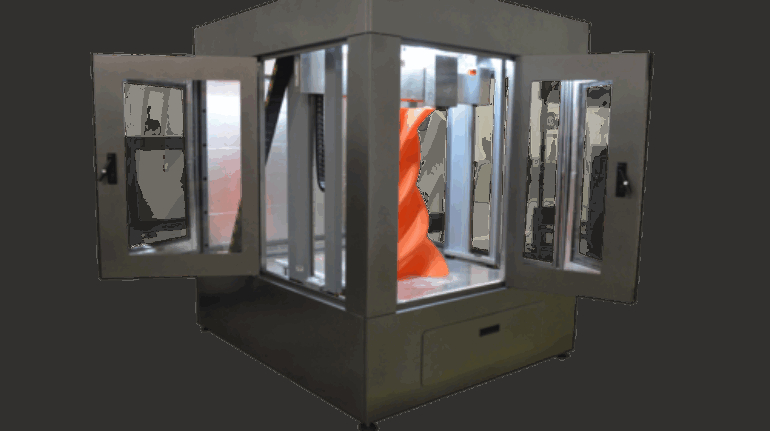

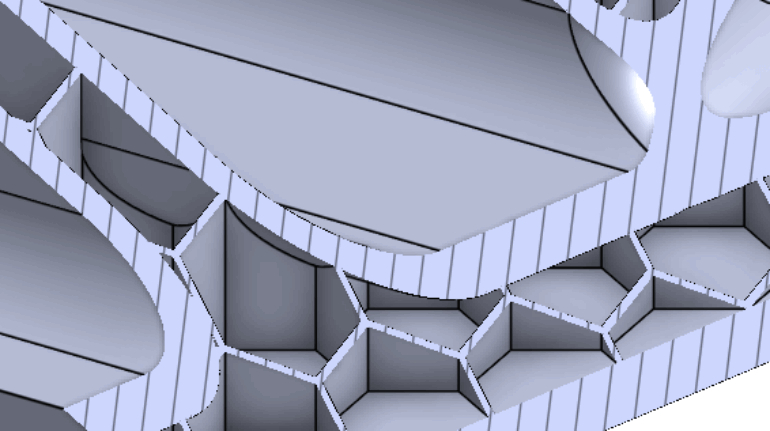

The Selective Laser Melting technology (SLM®) by leading German metal 3D printer manufacturer SLM Solutions enables the production of new 3D printed tire tread mould segments in shorter time, less expensive and using three-dimensional geometries for prototype and mass production tools.