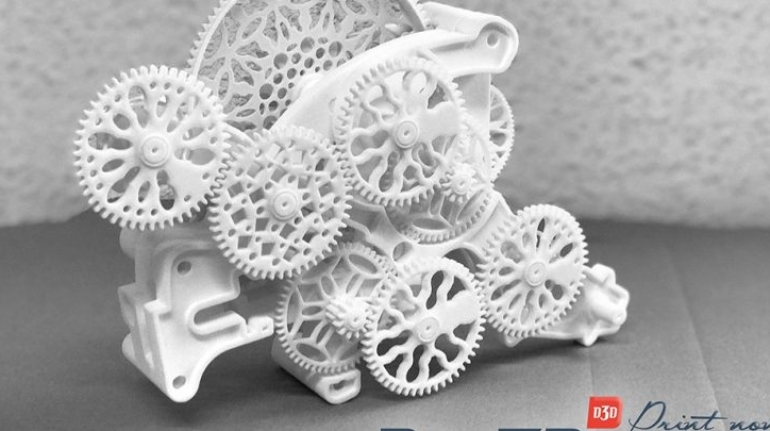

“Pathfinder to Flexible Manufacturing” Raise3D launches Pro2 series 3D printers 3D Printer Hardware

Raise3D is launching the Pro Series: a new series of printers developed with industrial grade components, to be smoothly implemented in Flexible Manufacturing solutions based on desktop 3D printing systems. The Raise3D Pro2 series systems look very similar to the N2 series, but they are two entirely different grades of printers.