Henkel and Bossard bring Loctite PR10 DLP 3D printer and resins to market 3D Printer Hardware

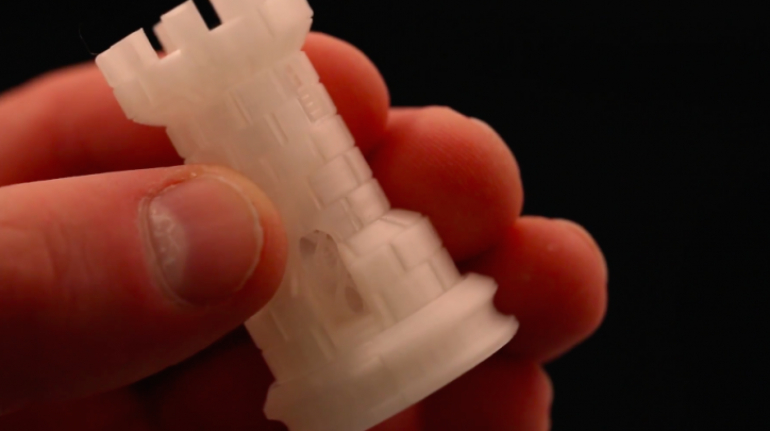

This may have slipped under the radar. The Henkel Group is not just establishing itself as a major developer and supplier of 3D printing materials for photopolymerization and powder bed fusion polymer system manufacturers like HP and Carbon. Through it proprietary Loctite brand, the company is also bringing its own Loctite PR10 DLP 3D printer and relative resin materials, including a 3D-printing specific Loctite bonder.