CL3VER Is Looking for a 3D Software Engineer AM Software

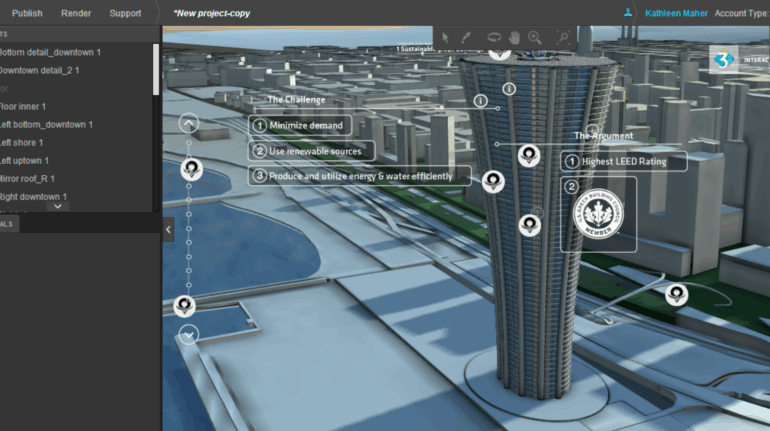

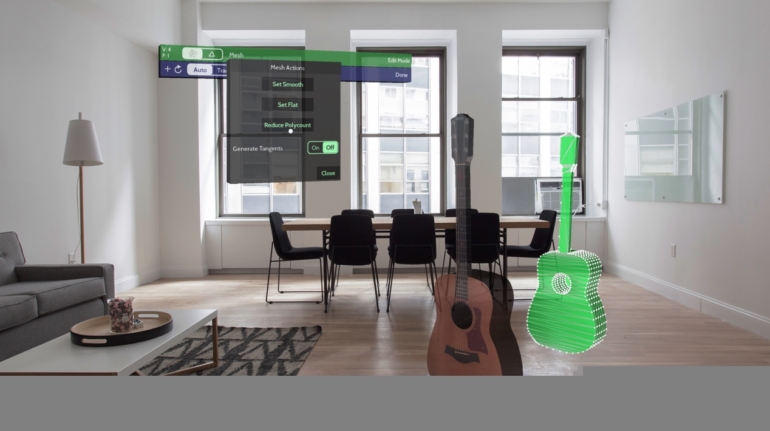

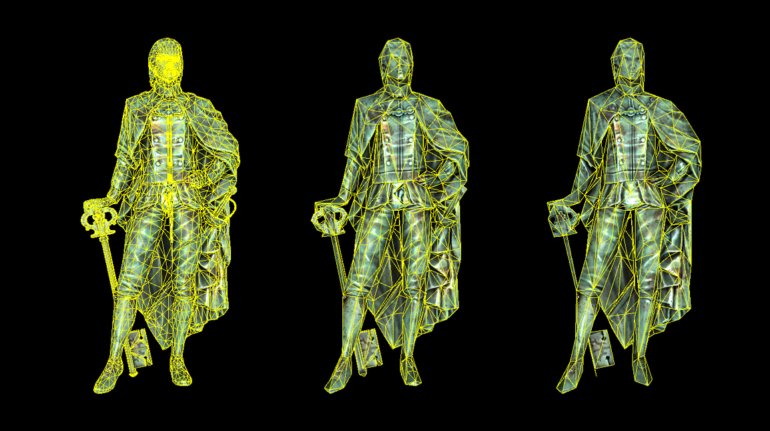

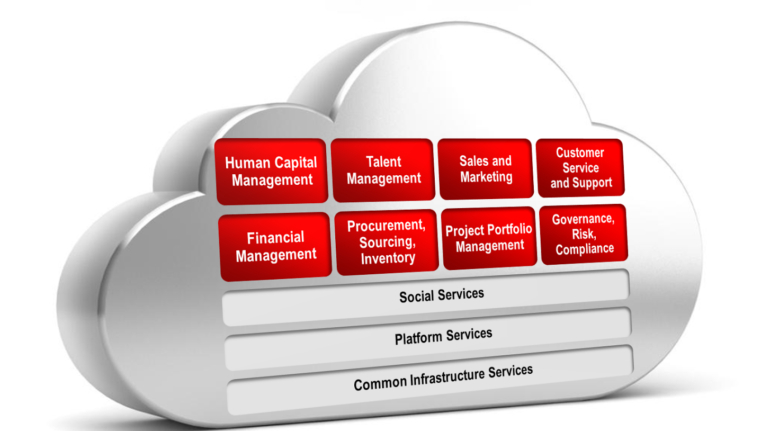

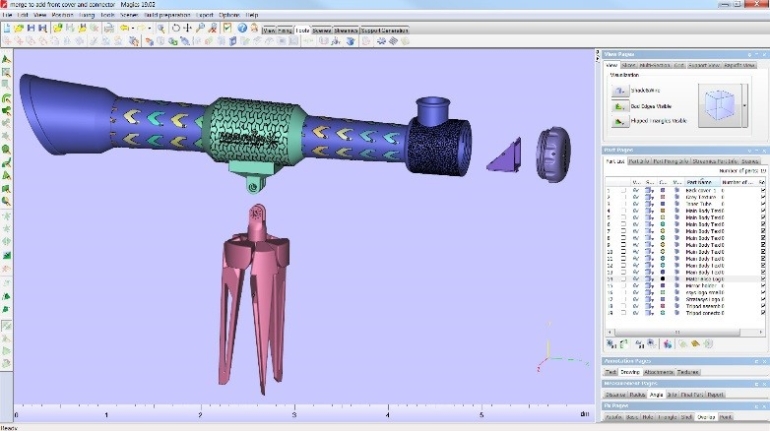

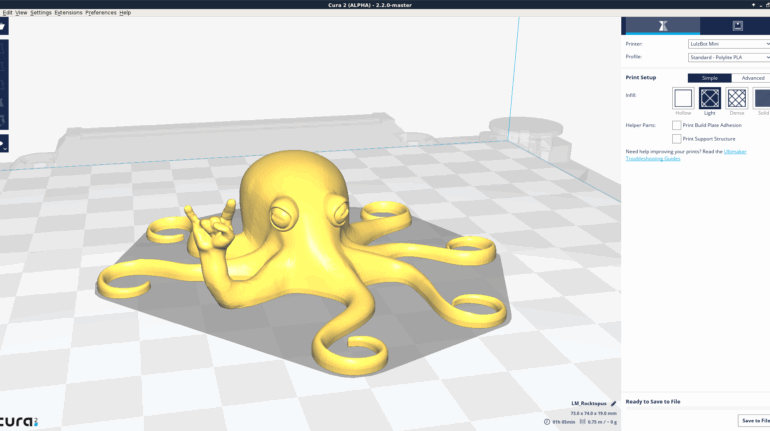

Are you passionate about working in a vibrant and innovative startup environment? Want to join a game changer in 3D visualization & VR technologies? You could be the perfect match for this company: CL3VER is looking for a 3D Software Engineer to help create the tools and content pipelines necessary to power its disruptive cloud based visualization platform.