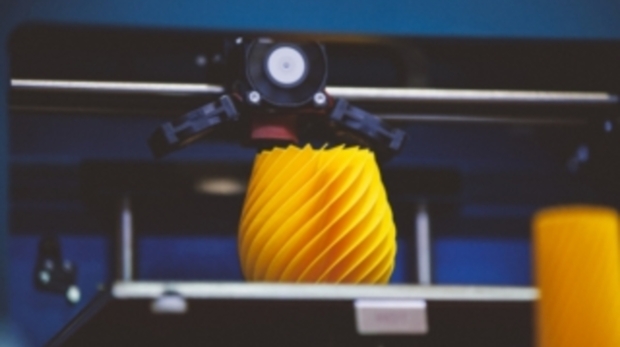

Sometimes you read news on generalist media about 3D printing and it’s hard to understand whether it is something real or just media hype. Most of the times it is media or social media hype (or inverse hype as in the recent “3D printing is dead” cases) especially when it concerns bioprinting applications. One of the biggest recent stories was the 3D printed rhino horn by a startup specializing in 3D printed wildlife products called Pembient. The idea is just perfect: using bioprinting and 3D printing technologies in order to produce a rhino horn that is sufficiently similar to the real thing that it would drive down the price of it so much that it would make it not worth going out and killing the rhinos for it. But can it really be done or is it just a stunt? Using bioprinting and bioreactors to produce animal products without the animals is the best chance we have (beside the whole world going vegan) to face to upcoming food crisis as well as the ethical and environmental issues that inevitably derive from intensive animal farming. A company called New Harvest has been leasing the bioficial food revolution and while progress is effectively taking place, a real solutions seems still decades away. This does not mean that some projects, such as Pembient’s rhino horn, might not become reality much sooner. Through Ourobotics Jemma Redmond I got in touch with Matthew Markus, the founder and CEO at Pembient to find out just what kind of timeline they expect. The premises are pretty good. As Markus writes in the Pembient white paper “Rhinoceros horn mainly consists of calcium and melanin embedded in a keratin matrix. It is produced by epidermal cells that undergo keratinization in a manner similar to the growth of human hair and nails (Nowell, 2012, p. 6). There are two basic ways to biofabricate rhinoceros horn. The first way involves 3D printing a biodegradable scaffold in the shape of a horn. Next, stem cells taken from a rhinoceros are cultured, differentiated into keratinocytes, and seeded onto the scaffold. Over time, the keratinocytes become filled with keratin protein filaments and die leaving behind a solid object. The second way starts with the production of rhinospecific keratins in genetically engineered microorganisms. Once purified, these keratins are then amalgamated with rhinoceros DNA and other biomolecules into a solid using a proprietary 3D printer. Whatever the process, the intent is the same, namely to produce an artefact that is physically and forensically identical to rhinoceros horn.” So the science and the technology are in the right place. The economics for this project appear to be in the right place as well. “… Suppose a seller can either obtain rhinoceros horn from the wild at $12,000 per kilogram or from a biofab at $8,000 per kilogram,” Markus writes citing a previous 1970 study by Akerlof. “Further suppose – he goes on – the seller can sell the acquired horn at $35,000 per kilogram. In this case, the markup for the wildsourced horn is 192% versus 338% for the biofabsourced horn. So, all things being equal, it is in the seller’s interest to sell biofabricated horn. On the other hand, assume a buyer knows there are biofabricated horns on the market. Further assume the buyer estimates that about 75% of the horns being sold are biofabricated. In this case, the expected value of any given horn is $8,750 per kilogram. Thus, it is in the buyer’s interest to either push for a price reduction or not transact at all.” Now the big question. When will this be possible and is it truly feasible from in terms of business model? “So far we have created what I would call “low-fidelity prototypes” using various different technologies either based on liquid resins or ceramics powders, as well as a more tissue-engineering based route whereby we created the biodegradable scaffold and applied the bioinks to it,” Markus said. This was the first approach in order Pembient to assess the market. The goal is to produce the rhino horns with the same exact materials, down to a DNA level, as the real ones, making it virtually impossible to distinguish. The powder Pembient developed contained a mix of keratine along with the ceramics, which represented a first step toward that goal.” “We want to be a commodity supplier, selling in Eastern and Western markets. We want to create a global, open market with significant business development opportunities for bioficial rhino horns. However – Markus points out – this is still far away and will require investments from others who believe in the benefits that it could bring in the long run. “The sad part is that if the rhinos were to become extinct, which is exactly what we would like to avoid, this business would make even more sense as the prices of the remaining horns would go sky high.” “We were really bullish when we first developed the powder and expected to be in the market within a year. This may not be the case but I do think that we could be able to present a valid product within five years at most.” Furthermore, as is the case with other forward looking 3D printing projects, the experience acquired will be used in other applications, especially in many other keratin based animal products that are in demand on the black market. So unfortunately the answer is no, the 3D printed rhino horn is not yet ready to save all the black rhinos as generalist media would have you believe, However the answer is also yes: Pembient is really working toward this goal and has thus acquired significant experience in 3D printing keratin based products. Hopefully they will perfect their method before the last rhino is killed.