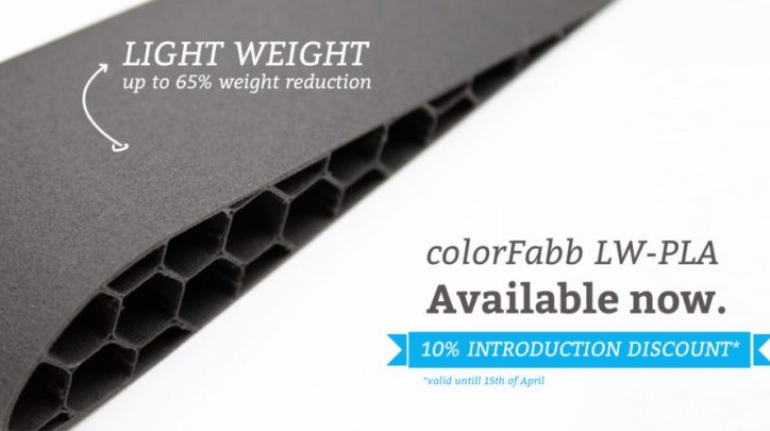

ColorFabb launches ‘foaming’ LW-PLA 3D printing filament Materials

3D printing filament company ColorFabb has presented its newest material release: LW-PLA. The light weight filament—the first of its kind—uses a novel active foaming technology to achieve low density, light PLA 3D printed parts.