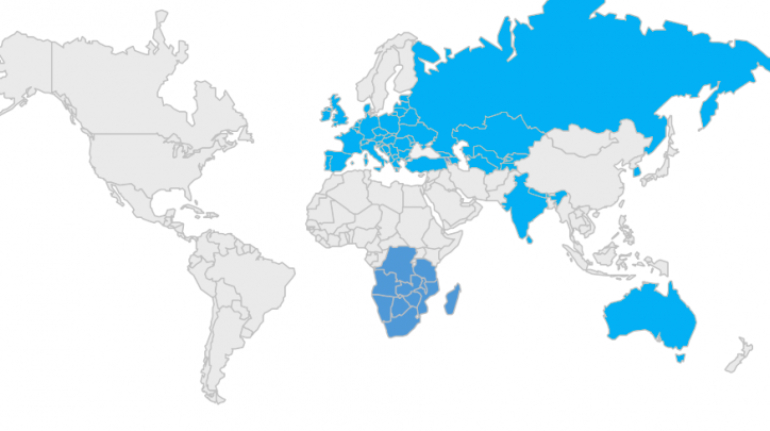

Sintratec brings its SLS 3D printers to U.S. market with new reselling partner Marketing and Content

Sintratec expands its distribution network to the USA. 3D printing expert 3DChimera from Miami, Florida now offers the Sintratec Kit via its online store and serves and supports the local Sintratec customers. With this cooperation, Sintratec can optimally serve local U.S. customers and shorten delivery times for the U.S. market.