Boeing Qualifies Stratasys’ Antero 800NA Filament for Aerial Applications

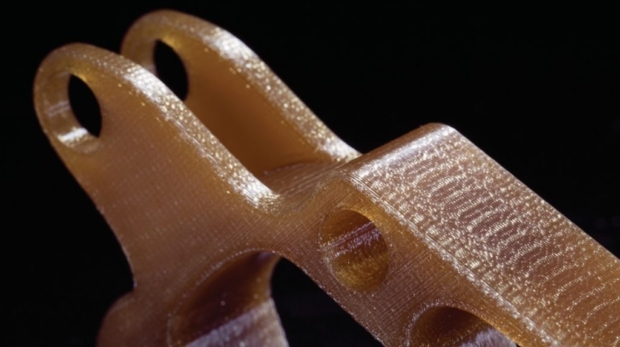

Aerospace manufacturer Boeing has a qualified 3D printer OEM Stratasys’ Antero 800NA thermoplastic filament for flying parts. In this way, PEKK-based polymers can now be used to additively manufacture end-use components on Boeing aircraft.