Renishaw Joins Futuralve in Development of New High-Speed Turbines Aerospace

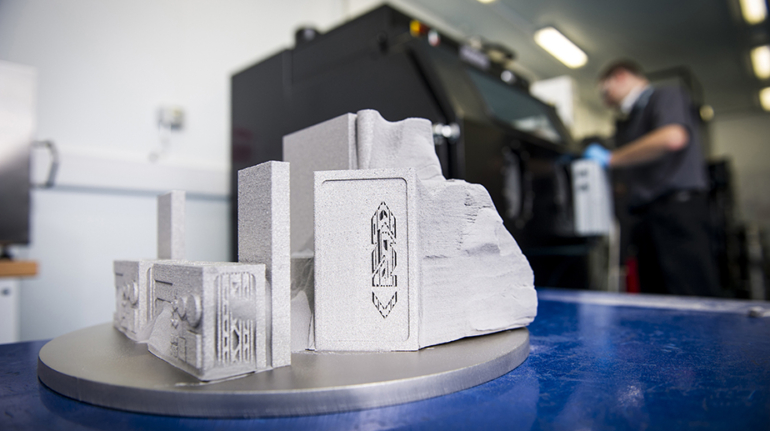

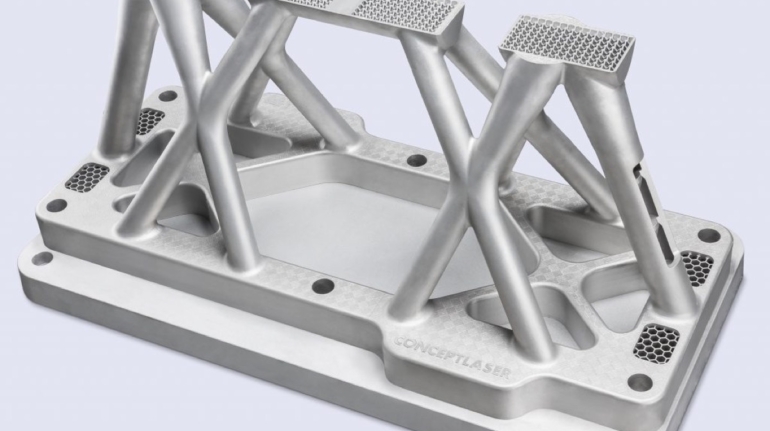

Renishaw, a global engineering company specialising in metrology and metal 3D printing, was born out of the aerospace business and its efforts in advancing the manufacturing of complex components have never stopped. Its Spanish subsidiary Renishaw Ibérica, S.A.U. is working with a unique selection of other Spanish engineering companies and research centres in a ground-breaking project which could change the way aerospace turbines are manufactured forever.