Ceramic tools show their potential where metal devices start to fail, with ceramics increasingly becoming the material of choice in many medical tools. Not only are they extremely heat and wear-resistant, they are also perfectly biocompatible and can be easily sterilized.

Designs of ceramic surgical tools have until now been strongly limited by traditional manufacturing methods, which are only economical if used for large quantities. Lithoz’s ceramic 3D printers combine a new dimension of design freedom with scalable and efficient mass production.

Unlocking new possibilities with 3D printed ceramics

In medicine, the 3D printing of high-performance ceramics unlocks previously unachievable qualities – not only in geometry, but also economically.

Large and small quantities of tools can be quickly and efficiently manufactured, while the many 3D-printable ceramics already in use in medical applications, including alumina, zirconia, silicon nitride and ATZ, greatly expands the range of possible innovative devices.

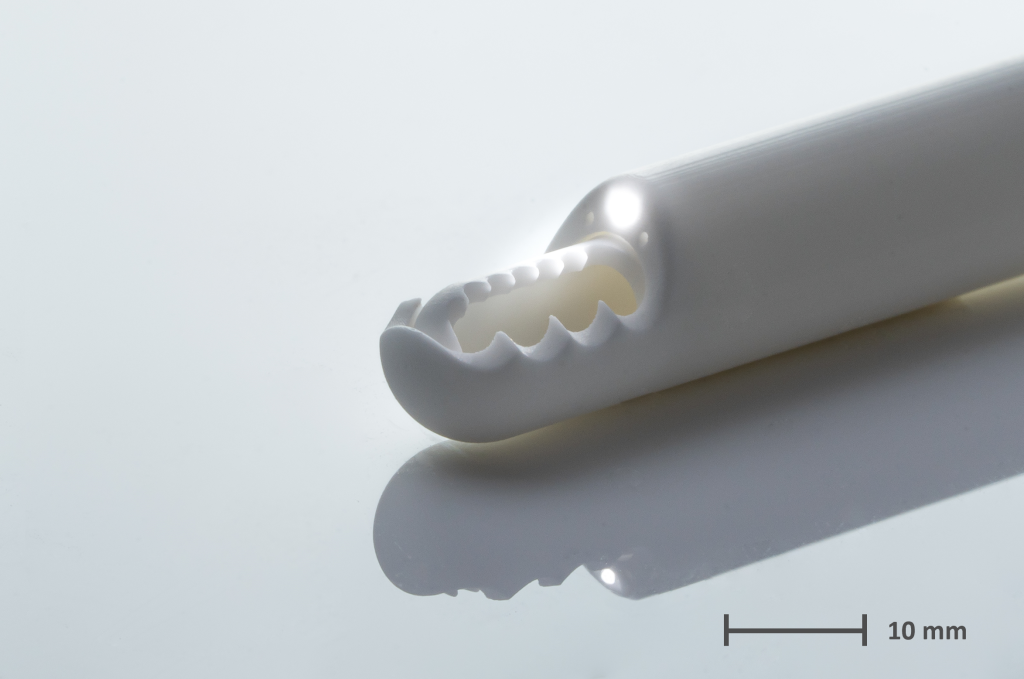

One example of 3D-printed ceramics is an arthroscopic knee shaver. Conventionally, these shavers are manufactured from metal in a simple tube. Thanks to 3D printed ceramics, new innovative design features can now be added.

In this example, the shaver tip has an integrated channel for optical fibers, allowing constant illumination upon the critical area. Such channels could also be used for rinsing, suctioning or for wiring an electrocautery tip.

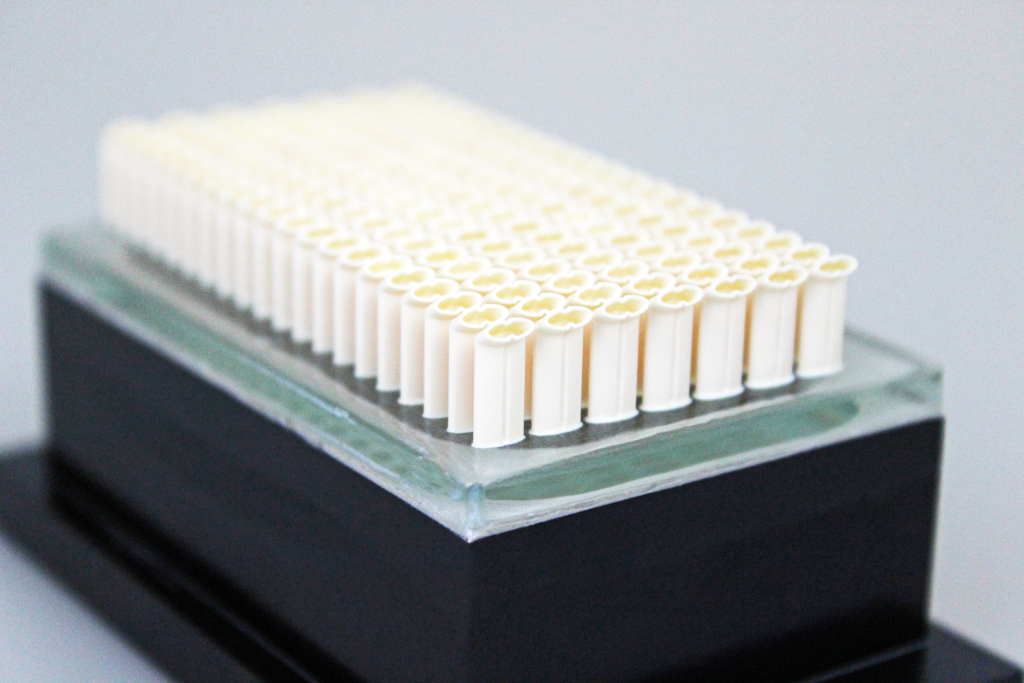

Burs for dental applications made of ATZ highlight the limitless possibilities opened up via combining cutting-edge geometries with the hardness and expanded durability of ceramics. Such ceramic components also avoid metal debris during operations – important for metal-free surgeries.

These parts, manufactured on the Lithoz CeraFab S65 Medical 3D ceramic printer with its 40 µm resolution, offer both enough detail to design precise and complex parts and a build envelope for efficient high-volume production. Over 100 burs can be manufactured in one 3D print run, meaning an individual bur is very cost-effective at less than €10.

Manufacturing on Demand

The German company Steinbach, a pioneer in ceramic 3D printing, recently showcased a 3D printed ceramic tube printed with Lithoz technology for use in the Da Vinci™ surgical robot.

12,000 tiny but high-precision tubes with sharp bends and inner contours were 3D printed to feed optical fibers through, featuring perfectly smooth surfaces with roughness values of Ramax of 0.4 µm and minimal wall thicknesses of 200 µm. This success shows how Lithoz ceramic 3D printing processes have already been successfully scaled to large-scale, serial production.

Lithoz multi-material 3D printing

Lithoz is already working on the simultaneous 3D printing of multiple materials in one single component.

When looking at bipolar tweezers for electrocauterization (a surgical method to cut through tissue or stop vessels from bleeding), for example, ceramic and metal are printed together using the Lithoz CeraFab Multi 2M30 multi-material 3D printer. This allows the components to combine the powerful insulating capabilities of ceramics with the conductive properties of metal. Such parts were once impossible to build, but are now being successfully 3D printed on a Lithoz CeraFab 2M30 Multi.

Ultimately, the rise of ceramic 3D-printed surgical tools marks a transformative chapter in modern medicine. With their precision, durability, biocompatibility and cost-effectiveness, these tools can entirely reshape surgical practices, streamline production, and enhance patient care.

As research and development continues, the medical community can look forward to a future where surgical precision and patient well-being are elevated to unprecedented heights through the fusion of ceramics and cutting-edge 3D printing technology.

You might also like:

Phase receives a $1.8M boost for its blood-brain-barrier model development: The primary focus of this grant is the development of a blood-brain-barrier model that accurately replicates the in vivo environment, aiming to address current limitations in treating neurological diseases and brain cancer. Partnering with Harvard Medical School’s Massachusetts General Hospital, Georgia Tech, and Virginia Tech, the two-year grant from the NIH’s National Center for Advancing Translational Sciences aims to develop and test 3D printing technology for microfluidics for biomanufacturing and creating organ-on-a-chip models.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Alex Tyrer-Jones

Leave A Comment