Rapid prototyping is based on 3D digital model of the prototype, and it is directly manufactured with rapid prototyping and numerical control processing technology. This technology is different from traditional mold forming process. It transforms the design into a real object in a short time, and corrects the design in the most intuitive way, improves communication effiency, and shortens the prototype development cycle.

Rapid tooling is an essential part of prototyping. The quality of the master pattern is particularly important for design improving and prototype testing, so it must strictly meet the production requirements.

Today, we’d liked to share the case of the rapid tooling process of car panels.

Step 1: Measurement and splicing of the master pattern

The 3D model of the dashboard is split and then processed by CNC machining.

In order to ensure the dimensional accuracy, the master pattern must be spliced on fixtures aligned by CMM ( coordinate measuring machine ). And the splicing and measurement processes are performed simultaneously.

Taking into account the shrinkage rate of the vacuum casting materials, the master pattern needs to be enlarged by a certain ratio. And the determination of the enlargement ratio needs to consider the sample size, structure, environmental temperature and humidity.

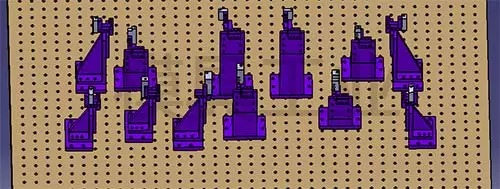

After the master pattern is spliced, post-treatments such as bonding, sanding, seaming, and primer spraying should be carried out. The fixture we used is shown below.

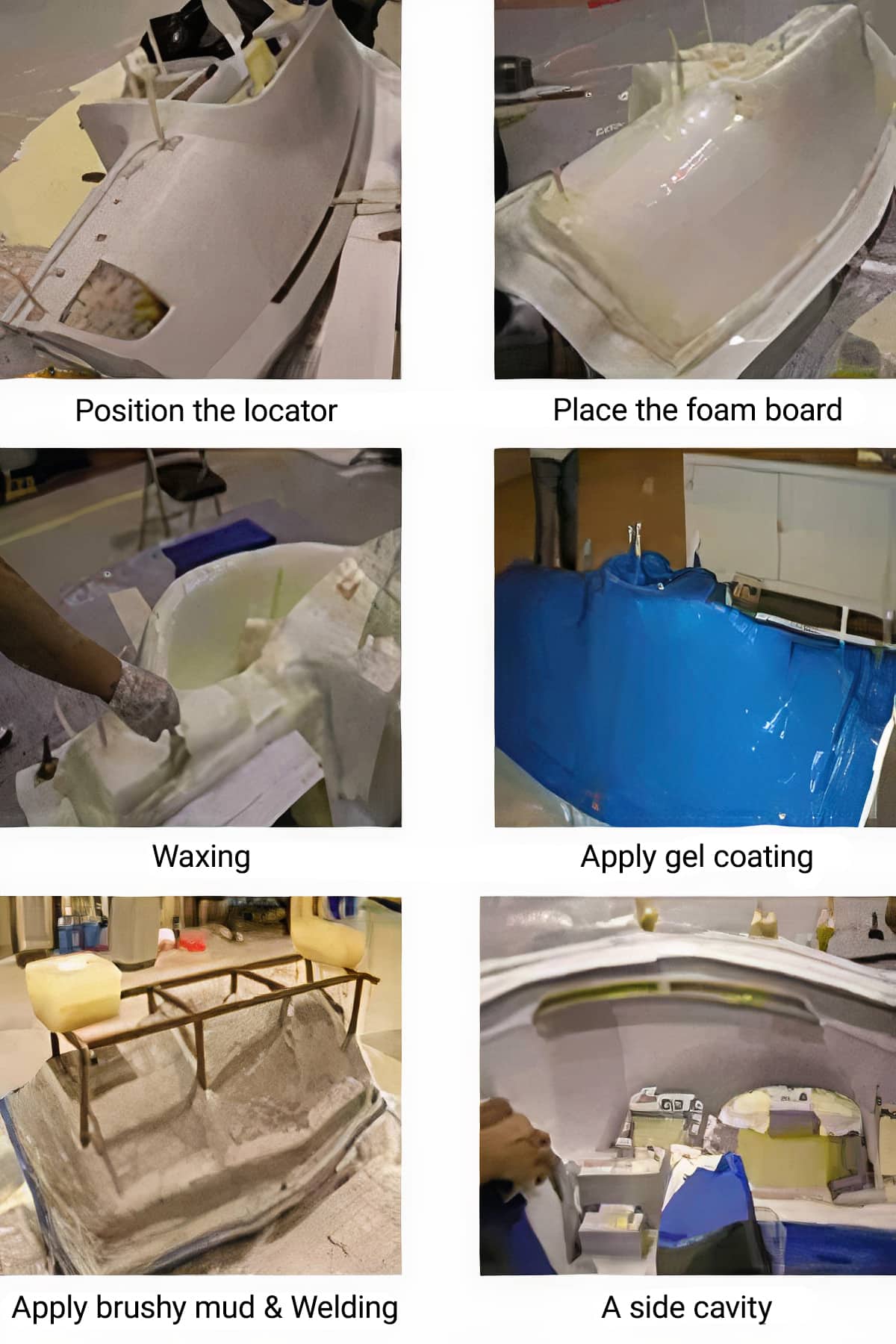

Step 2: Produce the A side of tooling

The visible cavity of the tooling is called A side, and the opposite structure is called B side.

The production of the A side tooling is completely carried out on the standard bracket, which can effectively fix the size of the tooling and prevent the master pattern from deforming under the gravity of the tooling. The specific process is shown below.

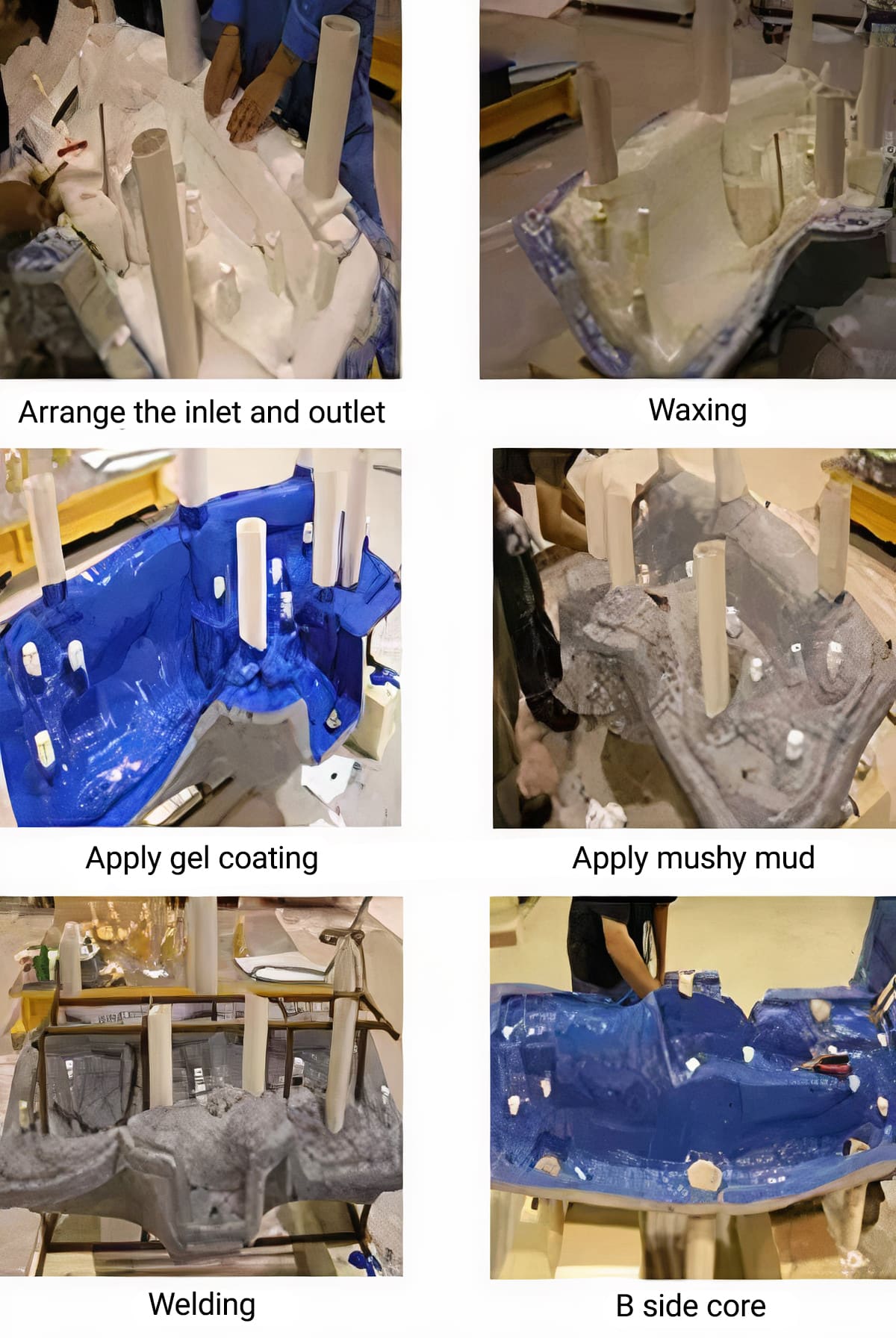

Step 3: Produce the B side of tooling

After cleaning the parting edge of the A side tooling, the B side tooling can be made. The specific process is shown below.

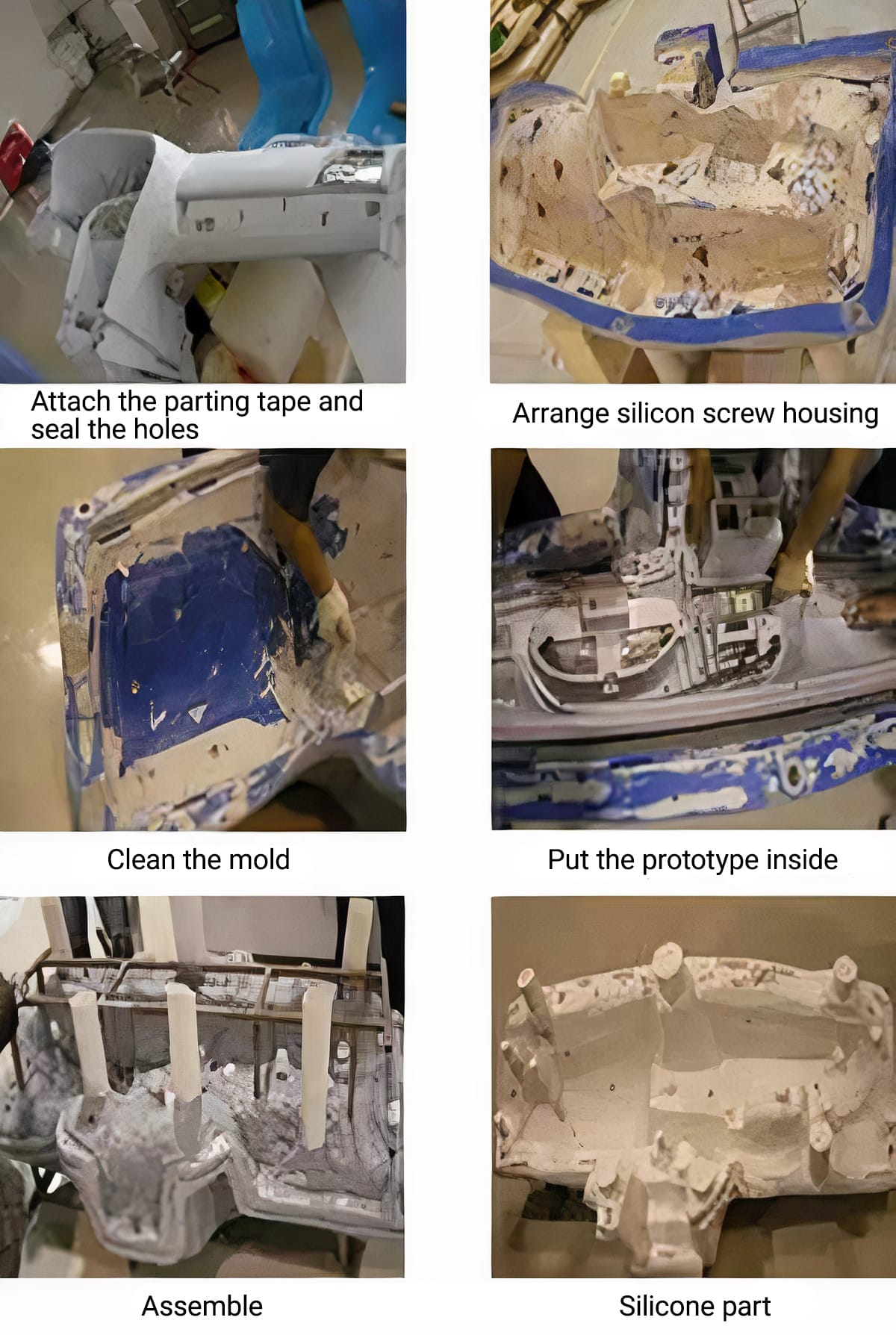

Step 4: Produce the RTV silicone mold

The RTV silicone mold can be made after the tooling on the A and B sides are completed. The specific process is shown below.

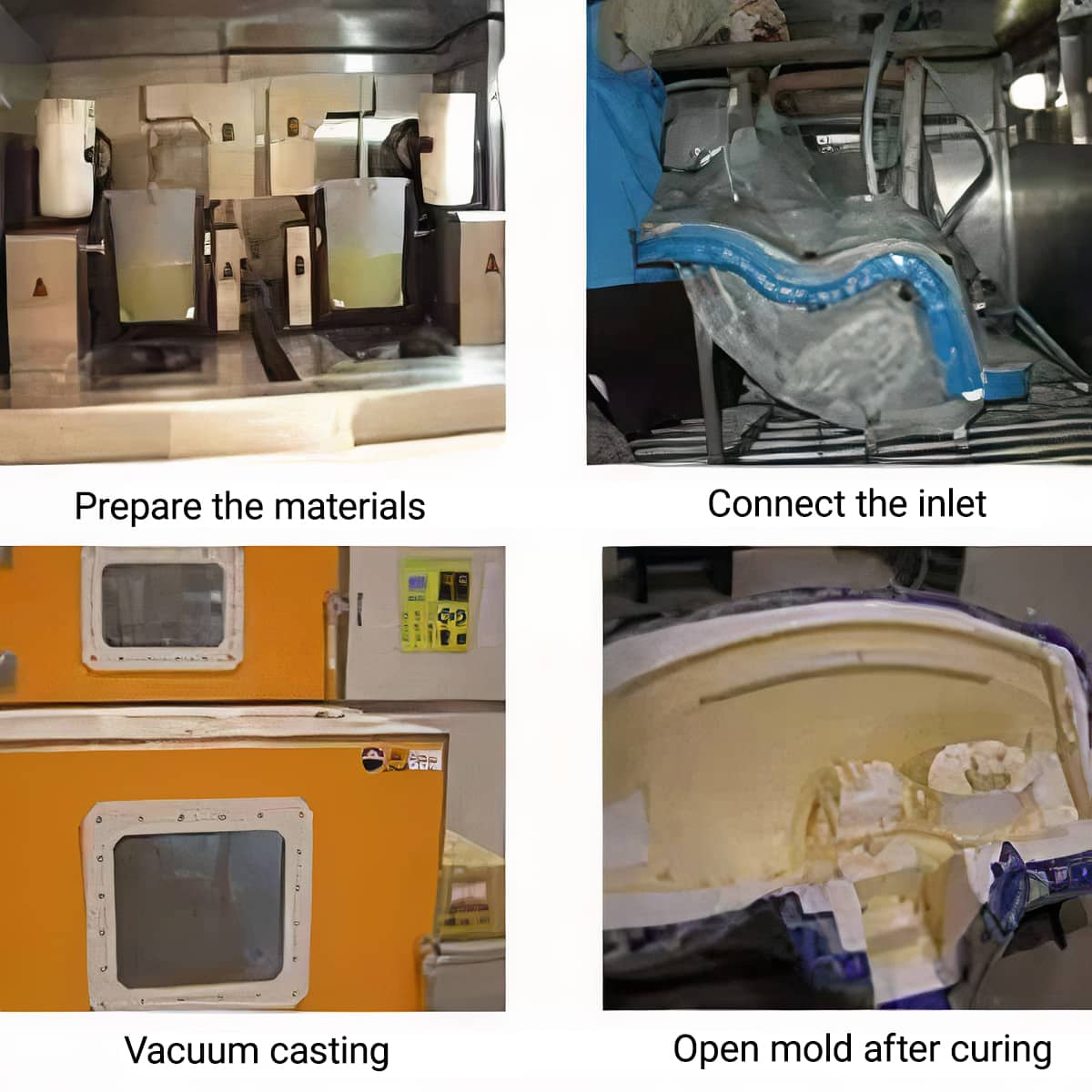

Step 5: Vacuum casting

After the mold is completed, low-volume production can be carried out. In this case, we used vacuum injection molding technology, and the process flow is shown below.

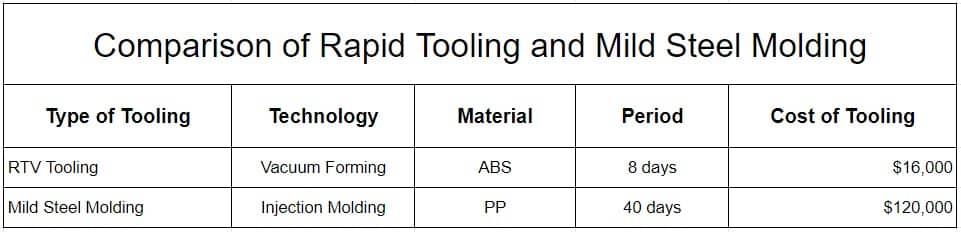

Comparison with traditional steel tooling

A simple comparison is made between the rapid tooling process and the mild steel molding process. As shown in the table, the RTV tooling process has obvious advantages in terms of production cycle and cost. It can greatly shorten the development cycle and reduce costs.

The advantage of the mild steel molding is that the dashboard can be made with the same material as the mass-produced parts.

How to choose the process should be determined according to the specific requirements of rapid prototyping during the trial production stage.