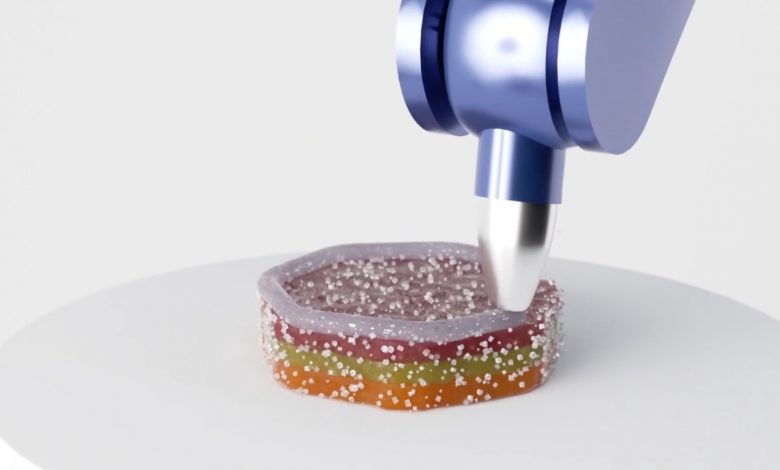

We’ve had a keen interest in Boston-based company Fortify since it was named a winner of Formnext’s 2018 Start-up Challenge. And for good reason. The company, which in 2021 raised $20 million in a Series B funding round, has pioneered a magnetic DLP 3D printing process for producing high-quality composite parts. The patented process, known as Digital Composite Manufacturing, is at the center of Fortify’s broader offering, which also includes filled photopolymers and a new software solution, Flux Developer, which gives users the tools, experiments, and workflows to develop and qualify filled resins for a variety of applications.