SprintRay, an industry leader in digital dentistry, has entered a partnership with Braces On Demand, an online platform for in-office printing of orthodontic fixed appliances, to provide automated, end-to-end 3D printing solutions to improve patient treatment times and productivity for orthodontic practices.

Manufacturing on Demand

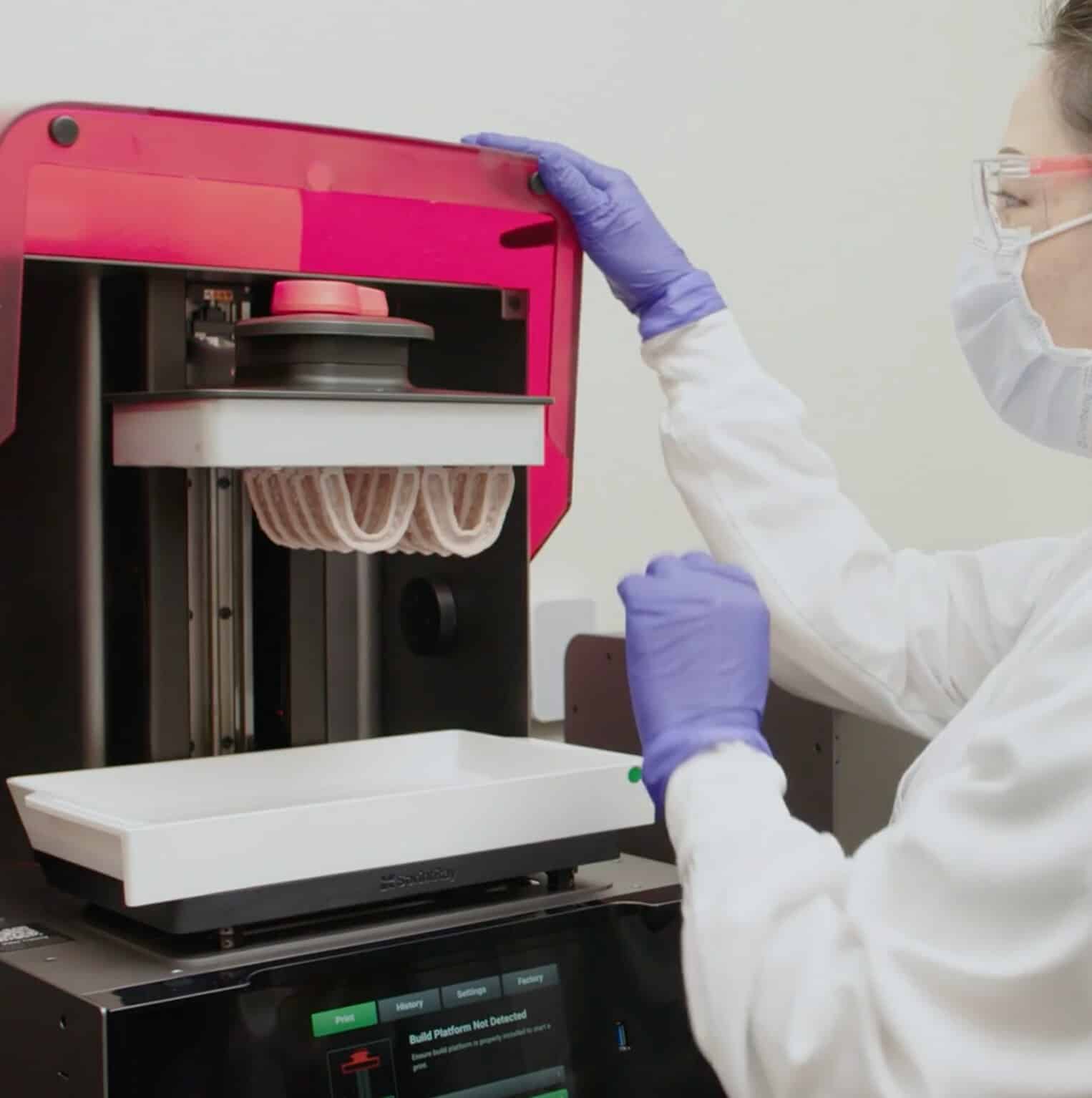

Leveraging the SprintRay 3D printing ecosystem, Braces On Demand provides orthodontists with the capability to 3D print brackets and fixed appliances in-office – saving time and money. The end-to-end SprintRay orthodontic 3D printing ecosystem features Pro S series 3D printers and ProWash and ProCure 2 post-processing machines built to innovate digital dentistry and deliver clinical results. This partnership between SprintRay 3D printing systems and materials and the Braces On Demand software enables orthodontists to 3D print a variety of fixed appliances, in under 30 minutes.

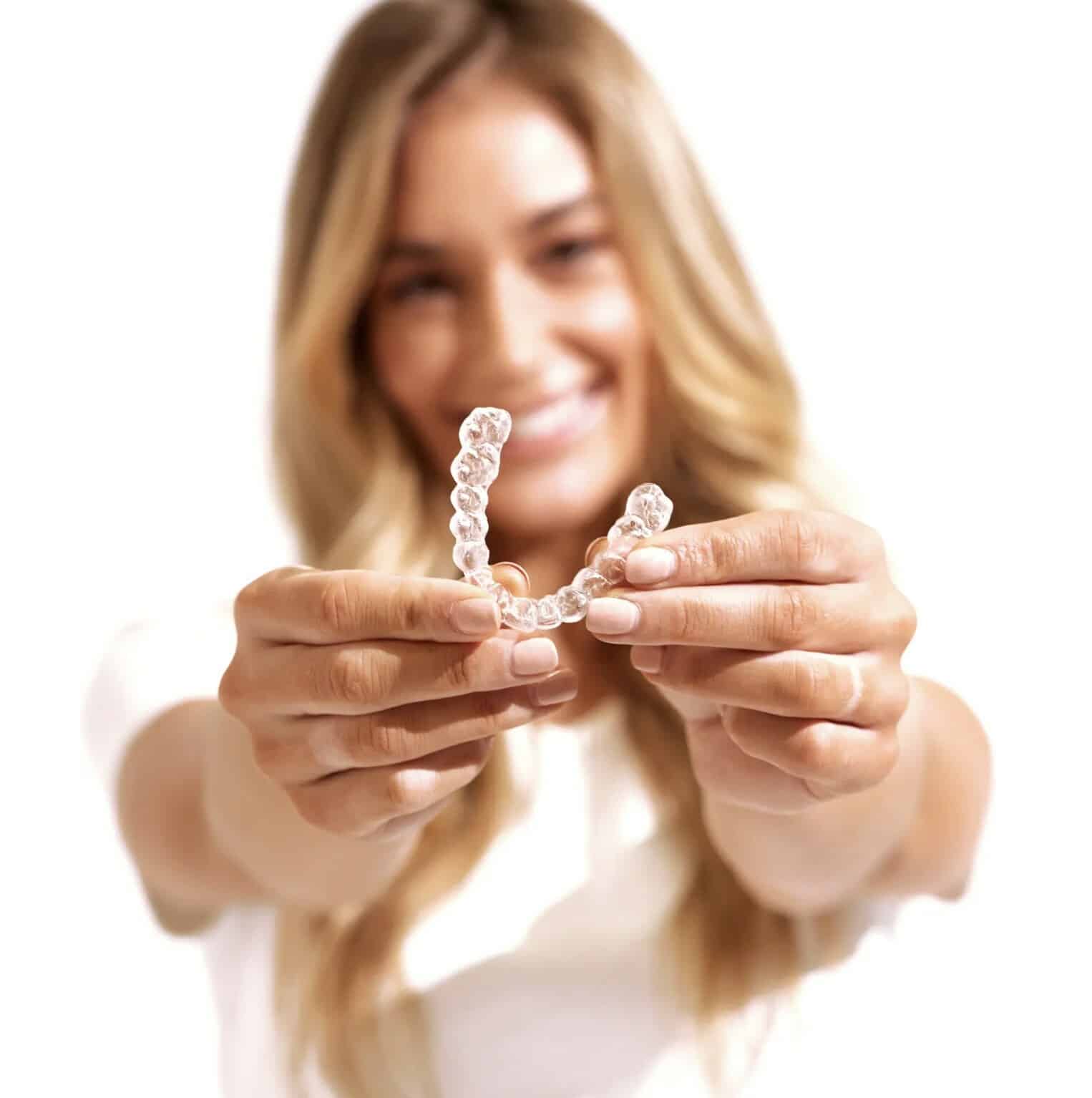

The ‘First Tray Today’ campaign provides SprintRay customers with in-office and digital marketing collateral to help their patients jumpstart orthodontic treatment. The campaign aims to improve patient awareness, case acceptance, and treatment success by providing patients with same-day clear aligners delivered by 3D printing within their first visit. First Tray Today campaign assets include a patient-facing website with a resource for patients to find orthodontists using the SprintRay 3D printing workflow for delivering same-day clear aligners, and in-office marketing materials to help orthodontic offices inform their patients about the ease and benefits of accepting aligner treatment.

You might also like:

Handddle and the French Air and Space Force renew collaboration: As an essential technology for the military industry, 3D printing offers numerous advantages, especially in the production of complex and custom parts. This is particularly advantageous for the production of obsolete spare parts, in emergencies, which is a necessity for modern armed forces. In industries like defense, processes must be perfectly documented, closely monitored, and validated at each step to ensure that finished products meet the strictest standards of quality, safety, and conformity. Thanks to Handddle’s Smart Farm micro-factory, the company offers a controlled, standardized, and resilient production tool capable of meeting the growing production needs and capacities of the forces.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment