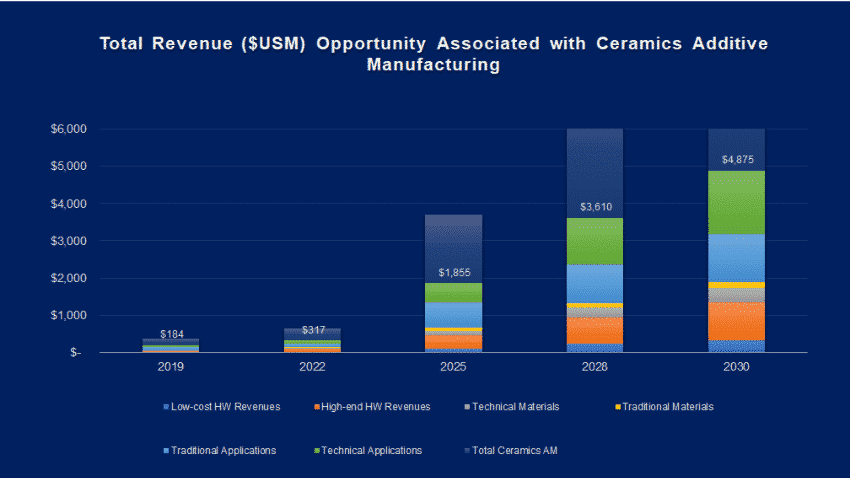

SmarTech Analysis has released the latest report on the ceramic additive manufacturing (AM) market, namely the production of ceramic additive manufacturing parts: 2019-2030. The report shows that even if the current dynamics related to the COVID-19 outbreak occur, by 2030, the revenue of the ceramic additive manufacturing market will still reach $ 4.8 billion. These opportunities are medium to long-term.

Ceramic 3D printing is still suitable for emerging technologies, although there are certainly many companies that have developed mature ceramic printing technologies. SmarTech predicts that this trend will change in ten years. With the full development and maturity of all major ceramic additive manufacturing technologies for mass production, the ceramic 3D printing market will reach an inflection point after 2025. After this inflection point, once the market has fully recovered from the COVID-19 slowdown, the company expects the market for ceramic additive manufacturing applications to triple in size.

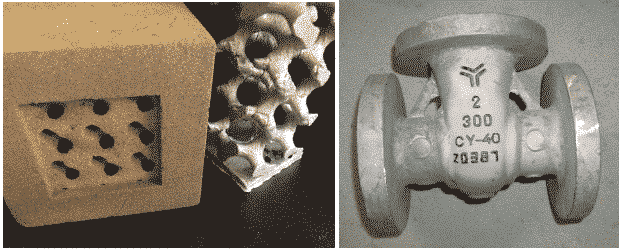

This is absolutely in line with the trend suggested by the development of serial 3D printing technology. HP ’s Multi Jet Fusion, ExOne ’s traditional binder jet, Xaar ’s high-speed sintering, and Prodways / 3DCeram ’s MOVINGLight all indicate that mass production of ceramic 3D printed parts is imminent.

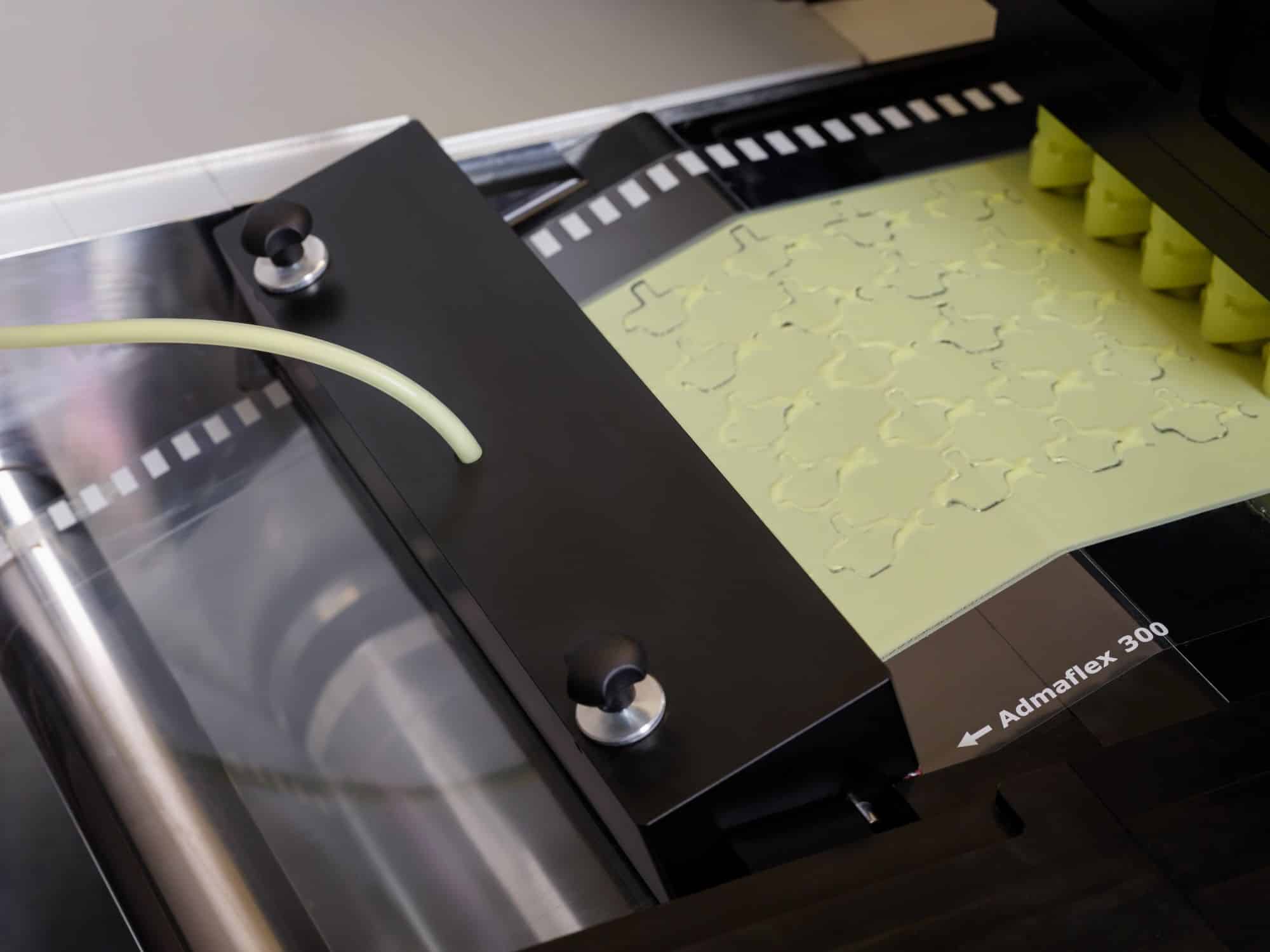

The report paragraph technology and traditional ceramic materials such as alumina 3D printing from such companies Lithoz or Admatec and sand printing from such companies ExOne. This also provides information for the specific applications covered in the report, from medical or electrical components using technical materials to sand cores and molds. Naturally, AM service bureaus that provide ceramic printing and the types of parts will be explored. Other companies discussed include: 3DCeram-Sinto, voxeljet, SGL Carbon, Schunck Carbon Technologies, XJet, Nanoe, etc.

Compared to the previous issues of the SmarTech ceramic report, this version will for the first time include new bonded ceramic 3D printed parts and materials, where green ceramic parts are made by hot extrusion of ceramic powder bonded in a thermoplastic filament matrix.

According to market research companies, this will also be reflected in the regional effect, and the Asia-Pacific region will benefit from more effective business management and manufacturing methods in the pandemic. SmarTech suggested that Asia-Pacific countries (especially China and Japan) have begun to use ceramic additive manufacturing, which is faster than European and American countries.

The complete catalog and the report itself can be found on the SmarTech website.