Shapeways, a 3D printing marketplace and service bureau, has added Nylon PA11 to its materials portfolio to enable the creation of 3D printed orthotics and prosthetics. As a result of an ongoing partnership with leading 3D printer OEM EOS, Shapeways’ offering of Nylon PA11 has been undertaken to increase 3D printing’s accessibility for medical professionals.

“Expanding our reach to the medical industry to make life-changing enhancements available is something we could have only imagined when we first opened our doors,” said Greg Kress, CEO of Shapeways.

“We look forward to working with the medical industry and creating products [that] make someone’s life better. This is what the 3D printing industry has been working towards and making it available to businesses of all sizes is a real dream.”

Shapeways and EOS

Shapeway was founded in 2007 and, at the time, EOS became one of the first additive manufacturing names to become a partner of the site. Headquartered in New York City, Shapeways facilities across the U.S. and Europe house multiple EOS 3D printers.

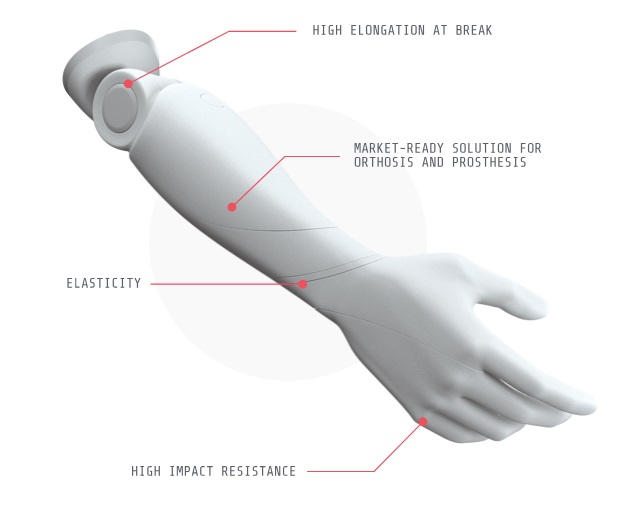

The EOS P 396 3D printer in particular, is enabling the production of PA11 parts at Shapeways. With high impact resistance and low water absorption PA11 is well suited to external medical applications. As such, Shapeways expects to be producing the links of prosthesis, braces, insoles and other supportive devices with the material.

Glynn Fletcher, President, EOS North America, comments, “PA11 has the potential to transform how the medical industry can use 3D printing to improve patient outcomes. It has the additional benefit of lowering the negative, ecological effects that are generally associated with petroleum-based plastics.”

Manufacturing on Demand

Shapeways expanding capabilities

In 2018, Shapeways was granted a further $30 million in funding to expand its services. In recent months, the company has also been broadening its 3D printing capabilities first in a collaboration with Stratasys and, following this, a partnership with Silicon Valley’s Carbon, giving Shapeways customers access to Digital Light Synthesis (DLS) technology.

Of the most recent PA11 addition, Fletcher concludes, “Collaborating with the industry visionaries at Shapeways has always felt like a privilege. Working together to combine their expertise, our technology with an eco-friendly polymer breakthrough seems like an appropriate extension to our complementary pioneering attitude.”

“We are proud to be part of the venture and look forward to seeing how far the technology, material, and collaboration can take us.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Tia Vialva

Leave A Comment