As one of China’s three major state-owned key air transport groups, Eastern Airlines operates a modern fleet of more than 600 passengers and cargo aircraft, and its routes cover 177 countries and 1062 destinations around the world. The newly introduced B777 wide-body passenger aircraft is even more encrypted The routes of major large and medium-sized cities in North America provide passengers with more quality flying enjoyment. In order to ensure the safe flight of each aircraft, China Eastern Airlines Technology Co., Ltd. undertakes the important tasks of route maintenance, regular inspection maintenance and component maintenance, and procurement.

The aviation industry is often regarded as a “conservative” industry because of its ultra-high safety standards. How did China Eastern think of introducing this new technology of additive manufacturing? In 2015, China Eastern introduced the first brand-new Boeing 777 passenger plane, and there was an error in the printing of the aircraft seat sign. This defect would cause chaos for passengers in this row of seats. If you purchase spare parts from the original factory, you have to wait 180 days, and the cost is about $ 1,000. The time caused by a small error is very expensive. Faced with the demand for customized components in such small quantities, engineers of China Eastern eventually decided to use 3D printing technology to find solutions. The production was completed in three days, and the chaotic effect caused by small errors was solved, and the conversion cost was only 50 yuan. It was the successful early adopter that allowed CEA Technology to see the practical application value of additive manufacturing technology, and also firmed up the plan to establish a laboratory.

China Eastern Construction’s additive manufacturing laboratory has achieved remarkable results

In 2016, Eastern Airlines Technology Co., Ltd. established an additive manufacturing laboratory, using ULTEM TM9085 material that meets the relevant requirements of FAA and CAAC, together with the Stratasys Fortus® 450mc industrial-grade 3D printer, to establish an additive manufacturing capacity. With the efforts of the laboratory team, China Eastern completed the first technological innovation in the domestic aviation industry to apply 3D printed cabin interior parts to civil airliners.

Within half a year of that year, the Additive Manufacturing Laboratory has developed more than 30 cabin parts, and produced more than 300 finished parts for assembly in the aircraft cabin, realizing the standard production process of 3D printing cabin parts. Leveraging the advantages of small batches, low cost and rapid manufacturing, customized design, development, and production of parts and components, solved the problem of long-term ordering and high cost of vulnerable parts in the past, made up for the shortboard of aviation material supply, and guaranteed the company’s opportunity The safe flight of the team also improves the passenger riding experience.

According to Chen Zhiyi, an engineer in the Additive Manufacturing Laboratory of Eastern Airlines Technology Co., Ltd .: “In the past, when the company lacked spare parts production capacity, on the routine maintenance of the route, the cabin parts showed cracks and other damage, and only new parts could be purchased through the original factory. This usually takes 60 days or more than three months, or even out of stock at all. Due to the limited quantity of each component at a time, if you find a factory to open a mold to make, the unit price is very expensive. At the same time waiting for this During the time, the defective parts on the aircraft will bring passengers a bad ride and use experience. Such problems are very common in the cabin, and the original parts are sold at a much higher price than the parts printed by 3D. Times. Therefore, we currently use 3D printing technology to provide a new and efficient solution to this problem. “

The efficient operation of the additive manufacturing laboratory has enabled China Eastern Technology to successfully establish a complete set of additive manufacturing component production and use processes from the proposal, component design, printing, and manufacturing to approval and installation. It is one of the transformation routes of China Eastern Technology Company. After the company gradually formed a competitive advantage of professional production and industrial integration, it was able to take the industry’s leading aircraft lifecycle comprehensive maintenance service provider.

Typical case: 3D printed “Electronic Flight Packet” bracket and large business class newspaper rack

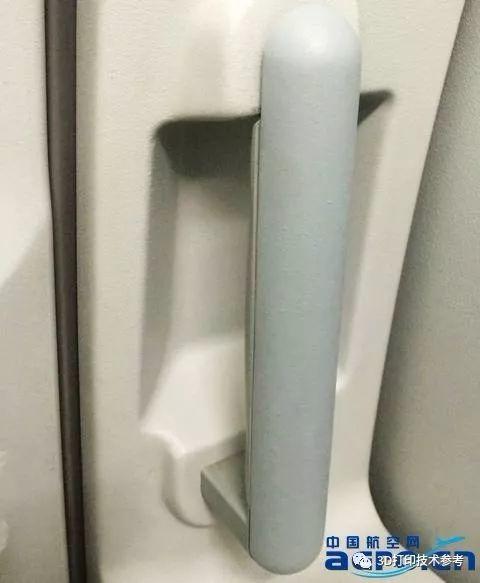

In less than three years of establishment, the laboratory has developed many 3D printed cabin components, such as seat armrests, aircraft door handle covers, luggage rack locks, and other interior parts, two of which are more prominent applications Case:

One is the electronic flight data packet holder in the cockpit. At first, this bracket did not exist on the introduced aircraft. Because today ’s pilots do not need to read the thick flight manual after encountering problems, they can check on the equipped electronic flight data package, so a bracket is needed to support the system. And fixed, the laboratory was commissioned by the company to develop the product. With the rapid manufacturing characteristics of 3D printing technology, the product design iteration quickly set a production plan. At present, the bracket has been used in the fleet of Airbus 330, 320, Boeing 737, and other companies. As a general auxiliary part, this product allows pilots to query flight information more safely and conveniently, and at the same time meet the installation requirements of various aircraft types and flexibly support user choices. At present, many airlines have consulted and purchased this program and products.

The second application is the newspaper racks behind the passenger seats. In B777 business class passengers ‘large newspaper racks, due to frequent collisions with food trucks, they are more prone to cracking and damage, which can easily scratch passengers’ fingers. Due to the difficulty in ordering this part, the laboratory immediately started to model and print the bookshelf, and then after post-processing and related approval, the 3D printed part was installed on the aircraft, which made up for the shortboard of the supply system and guaranteed passengers Passengers may not realize that this is a 3D printed part, but for Eastern Airlines, solving the problems in actual operation in the shortest time is the biggest change brought about by this new technology.

The above two cases were completed with the help of China Eastern Technology’s Additive Manufacturing Laboratory, which has a positive significance in making up for its shortcomings and improving the maintenance quality of the cabin, ensuring passengers’ riding experience.

ULTEM TM 9085 series of materials: the only FAA-certified aviation materials

The key reason why Eastern Airlines Technology Co., Ltd. chose Stratasys Fortus® series 3D printers is that Fortus ® series models support a large number of materials. There is a ULTEM TM 9085 material, which has been tested as a high-performance thermoplastic material. The United States Federal Aviation Administration (FAA) certification, with an ultra-high strength-to-weight ratio and FST rating (flame, smoke, and toxicity), is suitable for aerospace.

Chen Zhiyi engineer introduced: “Eastern Aviation Technology Co., Ltd. strictly implements the standards of aircraft manufacturers. Both Boeing and Airbus have accepted and approved ULTEM TM 9085 as a consumable for printing parts and passed the test to be installed on the aircraft. Related 3D The mechanical and flame retardant tests of printed aviation materials are completed by the manufacturer and reported to the local civil aviation administration. For compliance with the regulations and the consideration of safety standards, the 3D printing materials used by CEA Technology must meet the relevant regulations of China Civil Aviation At present, Stratasys’ ULTEM TM 9085 material meets this material standard, and the stable printing performance of the Fortus® series also meets the demand. This is also an important reason why China Eastern chose to cooperate with Stratasys. “

Future plans: from additive testing to final production

The additive manufacturing laboratory of Eastern Airlines Technology Co., Ltd. will transform from a pilot organization that meets the company’s internal needs into an advanced manufacturing department with product development, printing and manufacturing, post-processing, and approval for installation. From the laboratory to the research and development center to becoming a supply system with an aviation component production qualification, it has found a new profit point for the company.

In the future, the laboratory will continue to expand the scale, increase production capacity, and march towards customized production of parts in small batches. Engineer Chen Zhiyi said: “The new Airbus 350 aircraft that will be introduced in the future shows from public information that it is equipped with more than 1,000 3D printed parts. When we have certain 3D printing capabilities and are approved by Boeing and Airbus, It may be possible to directly manufacture small batches of parts locally. In the future, 3D printing will become popular as well as traditional processing technologies, and it is very necessary to actively make technical reserves. “

At the same time, the laboratory will also continue to explore the application of additive manufacturing in aviation, such as safety pins, storage boxes, 3D printing mold applications, the production of super-large parts, and customization of various aircraft maintenance training teaching aids. For maintenance purposes, continue to explore more possibilities. Using additive manufacturing technology to achieve zero inventory management of some parts, make on-demand, and take solid steps in digital management and intelligent manufacturing.