Scientists from the Israel Institute of Technology have developed an automated production line for 3D printing low-cost customized prosthetic limbs.

Within the team’s streamlined design process, amputees’ unaffected hands are scanned, tailored using CAD software and converted straight into an STL file ready to print. The resulting parts can then easily be assembled into lifelike extremities with advanced object-gripping capabilities, that provide patients with an enhanced quality of life, at the click of a single button.

Advancing accessible prosthetics

Losing a hand can drastically affect someone’s quality of life by increasing their level of dependency on others, but prosthetics can cost anywhere from $3,000 – $100,000. As a result, many amputees are priced out of customized devices, especially given that they often require an expensive manual fitting from trained specialists to achieve optimal performance.

Cost aside, prosthetics also suffer from several other issues that lead to sky-high rejection rates, including their appearance, weight, grasping force and lack of sensory feedback. Such patient rejection can also have serious consequences, causing joint and muscle degeneration, painful inflammation and a myriad of other potentially serious complications.

Using 3D printing, meanwhile, it’s now possible to reduce the number of assembly steps required to build prosthetics while creating more intricate designs, and a number of recent projects have done so successfully. However, developing low-cost artificial limbs with consistent properties and at a rapid enough pace to meet demand, has continued to remain problematic.

In an attempt to ramp up production and reduce reliance on trained specialists, the Israeli scientists have therefore developed a digital design pipeline, in which affordable prosthetics can be churned out with minimal manual intervention.

Creating an artificial limb factory

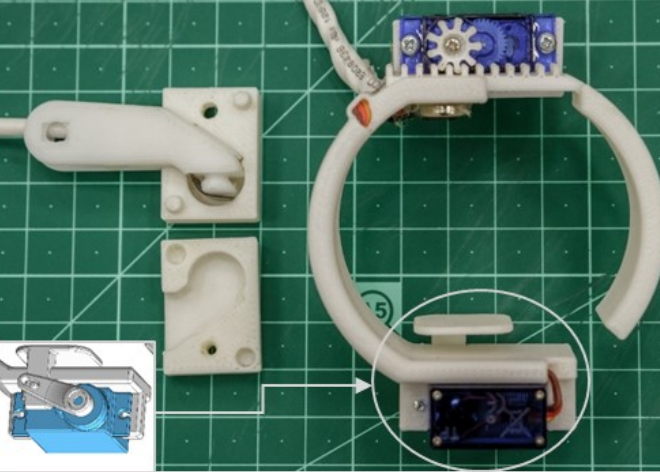

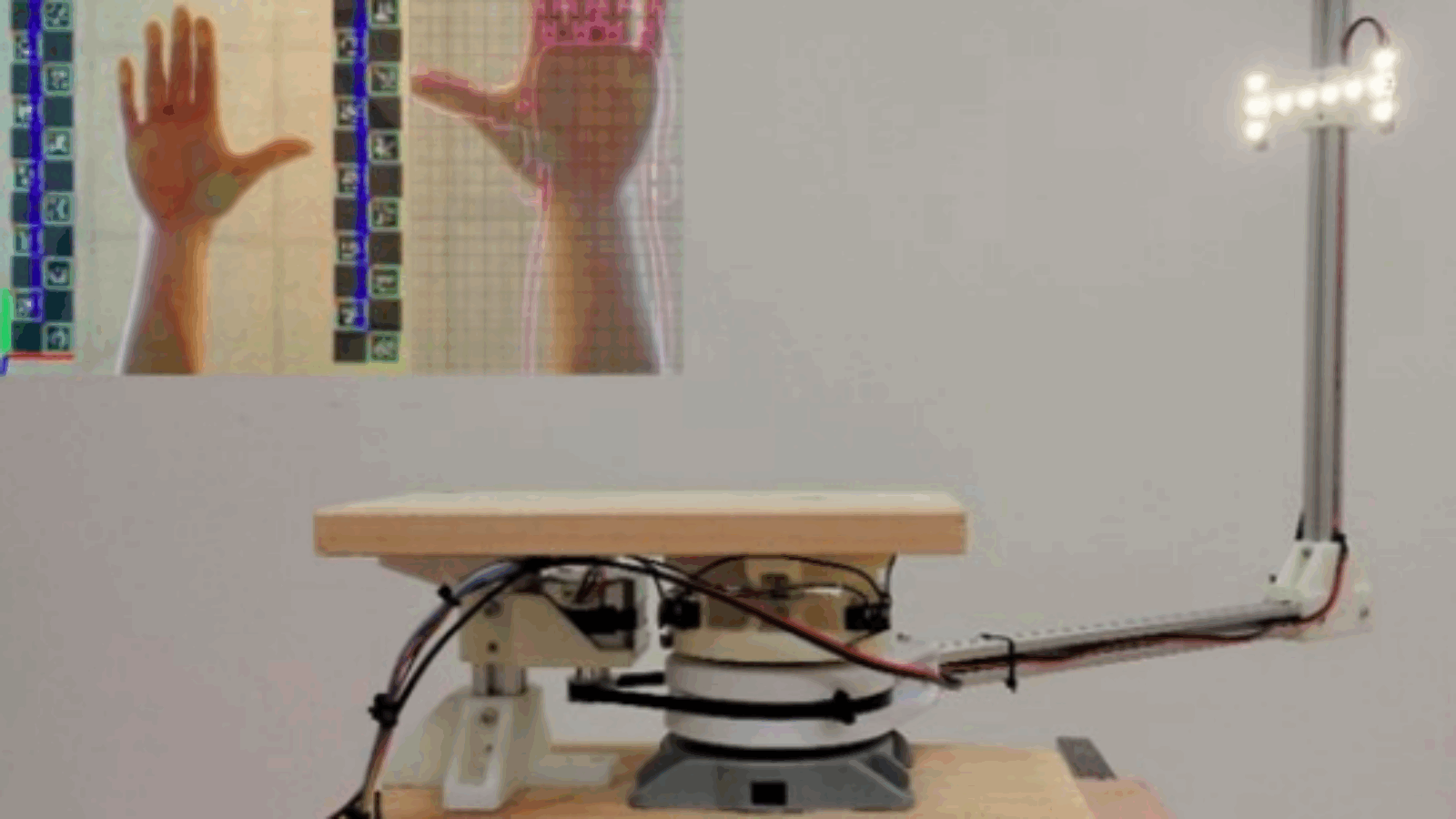

The researchers’ production line essentially consists of four steps: scanning, modelling, 3D printing and assembly. During the initial design phases, the artificial limb’s appearance can be tailored to match user preferences, and patients can pick between body-powered hands and more advanced EMG-controlled devices.

Once the prosthetic has been perfected, it’s automatically converted into an STL file and sent for printing. Although the scientists’ workflow still requires the resulting parts to be assembled manually, they found that previous steps can be optimized to shorten the process, making construction simple, quick and accessible for users.

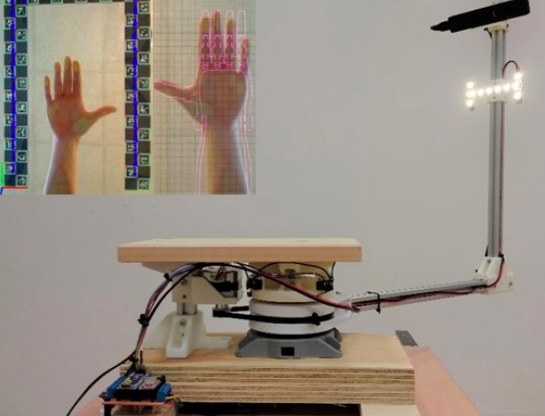

To make their setup as attainable as possible, the Israeli team even created a low-cost custom scanner based on an Intel RealSense camera, which came to around $40. The resulting prosthetics weren’t found to be low-quality either, as they proved capable of pouring liquids and holding household items for over 50,000 cycles.

Manufacturing on Demand

In other tests, the additive extremities demonstrated the ability to adapt their level of grip to either ultra-soft or rigid objects, with their motors stopping at different times depending on levels of resistance. While the prosthetics haven’t yet been rolled-out to prospective users, when shown to amputees, they’ve complimented the devices’ weight and realistic appearance, suggesting that patient rejection is likely to be minimized.

Ultimately, the scientists concluded that by removing the necessity for an expensive manual fitting, their 3D printing production line could dramatically reduce the cost of artificial limbs for those in need. Although the team didn’t put an overall price on their production pipeline, they concluded that the overall concept could “provide a much-needed leap in the field.”

Optimized prosthetic production

While it has been possible to 3D print prosthetics for several years, the industry’s focus has recently shifted towards making them more accessible to amputees.

Prosthetics manufacturer Partial Hand Solutions, for instance, has adopted Formlabs’ new Form 1 3D printer within its production process, enabling it to create 80 artificial fingers per day. Using the machine has also allowed the company to fabricate limbs that are both cheaper and better tailored to patient needs.

Similarly, researchers from the University of Lincoln have developed a 3D printed sensor-operated prosthetic arm that’s specifically designed for use by two-year-olds. Given that many children don’t get additive limbs due to their continuous growth, the device has been built as a more accessible affordable alternative.

Elsewhere, customized prosthetics have been developed to address the needs of patients with various other injuries, and scientists have even gone to the trouble of 3D printing testicles. Korean men reportedly have to pay over $715 for artificial gonads, and the additive balls are designed to provide a low-cost substitute.

The researchers’ findings are detailed in their paper titled “. ” The study was co-authored by Yair Herbst, Shunit Polinsky, Anath Fischer, Yoav Medan, Ronit Schneor, Joshua Kahn and Alon Wolf.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment