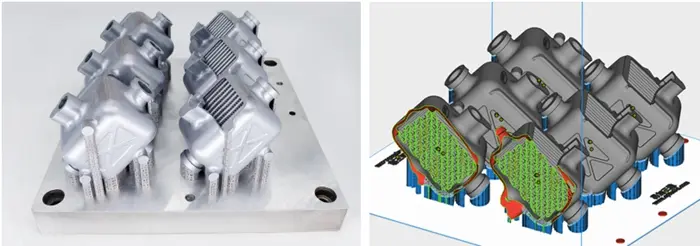

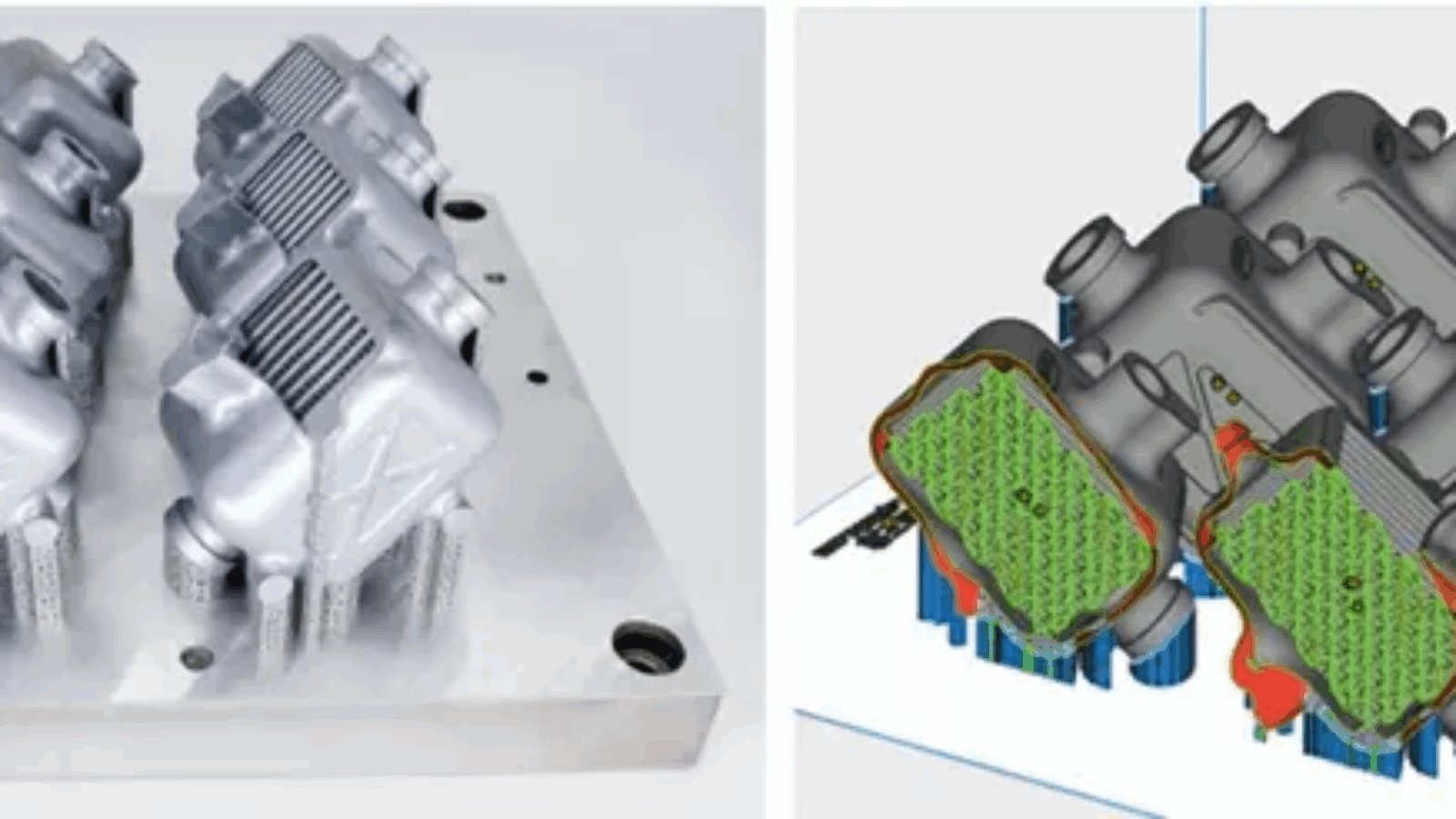

PWR Performance Solutions, based in Australia, decided to look into adding metal 3D printing technology to its current workflow, to stay at the forefront of manufacturing capacity. The heat exchanger pictured above was designed by PWR to test the capabilities of different aspects of 3D printing. PWR engineers designed the fin structure and tube array as a benchmark for testing minimum wall thickness, surface finish, and heat transfer efficiency. To produce the parts, PWR chose E-plus 3D as a supplier and ordered an EP-M250Pro MPBF system.

Automotive companies usually use AM technology for design verification, functional testing, and tools. Today, more and more applications are emerging such as complex integrated components, internal cooling channels, and heat exchangers.

Manufacturing on Demand

Traditional manufacturing technologies consisted of brazing many separate pieces to form a “core” which would then form tanks and weld to it. This is a complex manufacturing process with many steps and processes. The geometries of these radiators can be limited by the manufacturing process to relatively simple shapes.

Metal 3D printing, on the other hand, offers the opportunity to radically change the design and production of radiators, which compared to those produced in the traditional way have many advantages including access to integrated and complex design geometries. 3D printing allows users to fabricate multiple parts in one piece, reducing the amount of welding required and thus possible leak paths. With material added only where needed, component weights can be optimized for a given pressure and fatigue load requirement. With thin walls of up to 200 microns, small and complex channels can be incorporated, which means that engineers can design heat exchangers with a larger internal heat transfer area, thereby improving their performance.

Heat exchangers and radiators are important in industrial temperature control equipment as they allow heat to be transferred from one fluid to another. This, in turn, allows the equipment to operate at the temperature at which it was designed to be most efficient, preventing damage caused by overheating. Most radiators are made of aluminum due to their lightweight, high usability, and good thermal conductivity.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Andrea Gambini

Leave A Comment