San Francisco biotechnology company Prellis Biologics has launched a web-based platform for the generative design and download of 3D printable tissue scaffolds. Named TissueWorkshop™, the platform has been created to reduce the amount of time required to create such structures, freeing experts from labor-intensive design cycles.

Melanie Matheu, Prellis Biologics founder and CEO, explains, “Every day I saw my expert team toiling away designing CAD files by hand. The time it took to design a single file is prohibitive for us to quickly answer relevant 3D tissue engineering questions.”

The launch of TissueWorkshop follows the company’s successful $8.7 million Series A funding round led by specialist technology capital firm Khosla Ventures in August this year. The platform has also been developed in close collaboration with Swedish 3D bioprinter manufacturer CELLINK, a strategic partner of Prellis since December 2018.

Kidney vasculature in “12 hours or less”

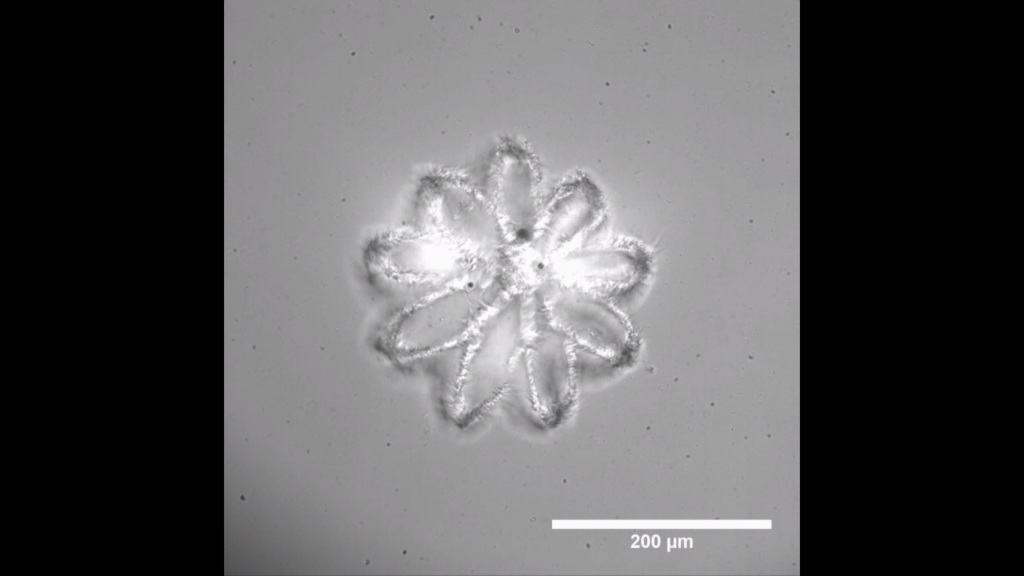

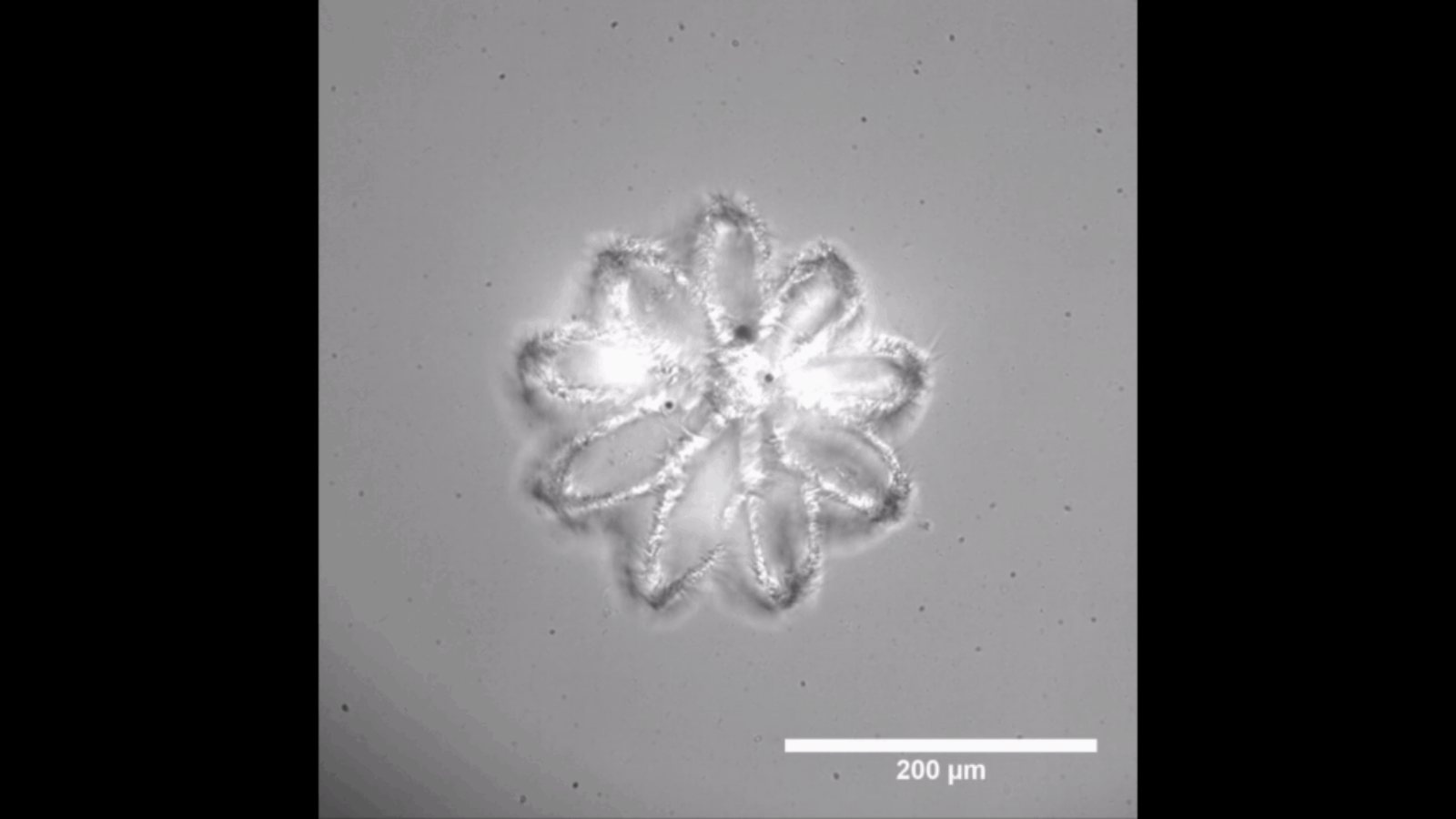

Prellis Biologics is the developer of a unique method of holographic 3D bioprinting. Targeting high print speeds, Prellis’ method is a high-resolution version of more common vat polymerization technologies. It uses a multi-photon laser to cure materials containing live cells.

Partnering with CELLINK, Prellis’ holographic 3D bioprinting technology has been added to the extrusion capabilities of the BIO X system, creating the Holograph-X machine. Described by Erik Gatenholm, CEO of CELLINK, “The Holograph-X Bioprinter enables in-lab manufacturing of capillary-containing organ structures and tissues for transplantation, therapeutics screening and complex 3D culture development.”

Prellis’ targets with the system, and material products like its Vascular Tissue Blanks, is to 3D print the entire vascular system of a kidney in 12 hours or less. Prior to its $8.7 million funding round earlier this year, the company took a necessary, rudimentary step toward this goal, reporting that a team at Stanford University had successfully implanted tissue made using its materials in a live animal. Such developments are what the company seeks to facilitate through the launch of TissueWorkshop.

Manufacturing on Demand

CAD for tissue engineers

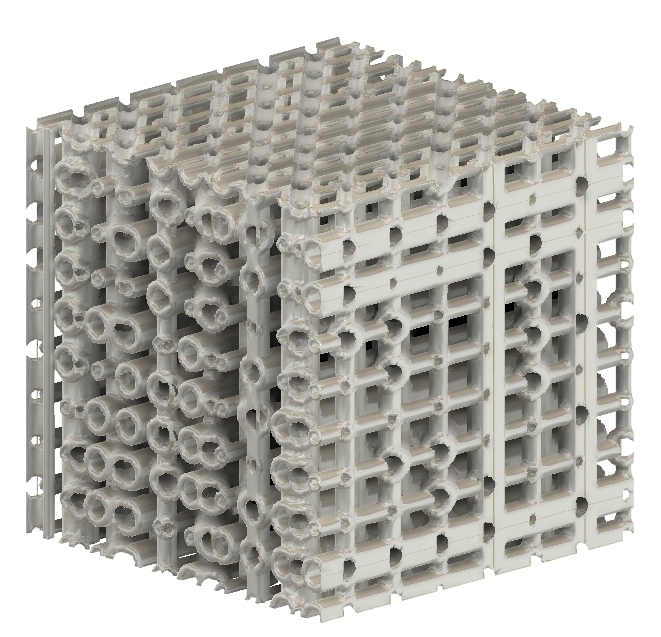

TissueWorkshop is designed for use by biologists and tissue engineers. As such, it offers an alternative, and specialized, design interface for their purpose in comparison to more traditional, wide-use CAD platforms. It was designed with principles commonly used in video game development and 3D animation instead. “The gaming industry has poured tremendous resources into tools that are often unfamiliar to those outside the sector,” commented Gavan Wilhite, founder of AltspaceVR that developed TissueWorkshop with Prellis and CELLINK. “It’s a special joy to use them to accelerate the positive impact that tissue engineering has to offer.”

Using desired parameters, the tool can be used to generate random scaffold designs that can then be downloaded as an .stl. “Finding the best architecture has been incredibly challenging due to the inability to scan potential 3D structures in an unbiased way with available CAD programs,” added Erin Stephens, PhD, Director of Tissue Engineering at Prellis. “It would simply take too long.”

Though designed with the capabilities of the Holograph-X and the BIO X in mind, Prellis asserts that files made on the platform can be 3D printed on most systems with a resolution of between 50 and 100 μm.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Beau Jackson

Leave A Comment