Two postdoctoral researchers at UC Santa Barbara, Renxuan Xie and Sanjoy Mukherjee, developed the first 3D-printable “bottlebrush” elastomer. The new material results in printed objects that have unusual softness and elasticity that closely resemble those of human tissue. The researchers’ findings were published in the journal Science Advances.

These polymers are significant because they do not contain water that artificially softens them. They can form implants less likely to cause inflammation, which will make medical devices much more successful. They will also resist biodegradation in the body because engineers do not have to worry about retaining water that has been artificially inserted. The absence of water will also prevent post-processing defects, like warping or cracking, because no water exists to evaporate from the solvent.

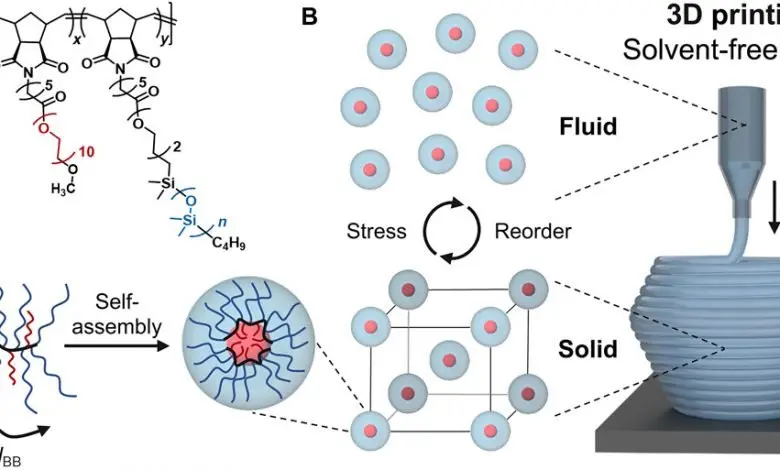

Bottlebrush polymers have additional polymers attached to the linear backbone, leading to a structure more akin to a bottle brush you might find in your kitchen. The bottlebrush polymer structure imparts the ability to form extremely soft elastomers. Conventional elastomers (think rubbers) are, on the other hand, stiffer than many biological tissues. The size and shape of their constituent polymers, which are long, linear molecules that easily entangle like cooked spaghetti, cause the rigidity.

Manufacturing on Demand

Printing bottlebrush elastomers allows manufacturers to create objects that require careful control over their dimensions. New possibilities for 3D printing range from biomimetic tissue to high-sensitivity electronic devices, such as touchpads, sensors and actuators.

Xie’s and Mukherjee’s key discovery involves the self-assembly of bottlebrush polymers at the nanometer length scale, which causes a solid-to-liquid transition in response to applied pressure. This material is categorized as a yield-stress fluid, meaning it begins as a semi-soft solid that holds shape, like butter or toothpaste, but when sufficient pressure is applied, it liquefies and can be squeezed through a syringe. The team exploited this property to create inks in a 3D printing process called direct ink writing (DIW).

The researchers can tune the material to flow under various amounts of pressure to match the desired processing conditions.

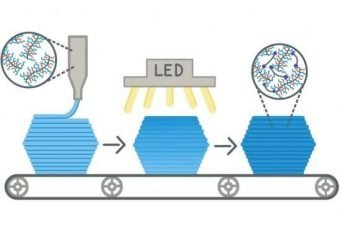

Once the object is printed, UV light is shined onto it to activate synthesized cross-linkers included as a part of the ink formulation. The cross-linkers can link up nearby bottlebrush polymers, resulting in a super-soft elastomer. At that point, the material becomes a permanent solid: it will not revert to its liquid form.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Adam Strömbergsson

Leave A Comment