HP's 3D printing field is a menacing situation. The nylon machine released last year is not complete. It has recently launched a metal binder injection molding system. While the whole industry feels stunned, the launch of Metal Jet is also expected. HP It is about to stir up the nerves of the entire 3D printing market .

In terms of the technical form introduced by HP, the most red-eyed estimate is not 3D Systems or Stratasys, but EOS, which is invaded by the mainstream technology market, and other equipment manufacturers engaged in powder bed molding technology. While Hewlett-Packard introduced metal printers, EOS , a traditional old metal printer manufacturer, released the new M300-4 almost at the same time, but it attracted little attention . As for whether the two competitions are strong or not, we will not delve into it, but HP publicly claims that Metal Jet has increased productivity by 50 times, and the cost is far lower than other metal binder injection technologies, which is a bit excessive . The author compares HP Metal Jet and EOS M300-4 with the currently published data.

Molding method

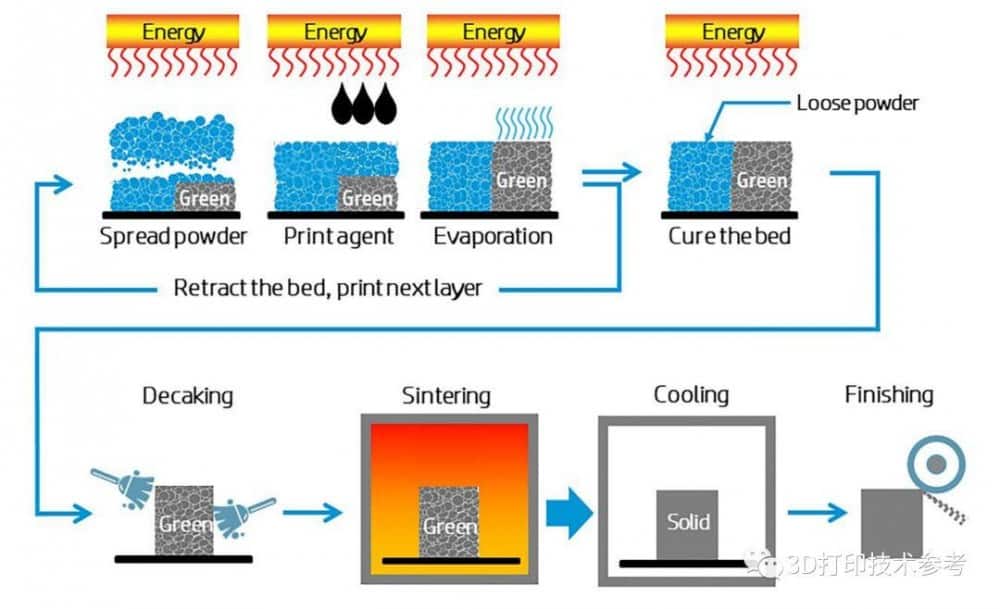

The essence of HP Metal Jet, like the DM production released by Desktop last year, is to use binder injection molding, and then enter the furnace to sinter.

HP binder is a water-based polymer liquid agent, which is sprayed through a thermal inkjet print head. The binder is immersed in the powder gap through the capillary force on the powder bed to achieve uniform distribution and combine the metal particles together under high temperature irradiation At the same time, the solvent is partially volatilized. After the printing is completed, the parts are sintered in the furnace, and the binder decomposes in the process. According to the data published by HP, the density of the parts is 93%.

As for EOS M300-4, it is based on laser forming and will not be repeated here.

Molding efficiency

The EOS M300-4 has a molding size of 300 x 300 x 400 mm and has a four-laser system. Compared with a single laser or dual laser system, the M300-4 can definitely improve production efficiency . According to information disclosed, the speed of this series of printers has increased by 4-10 times compared with M290, and the cost of parts has been reduced by nearly 50%.

Compared with laser point-by-point scanning, surface forming is naturally much faster . The HP metal machine has a forming size of 430 x 320 x 200 mm and is equipped with two rows of print heads, each with three 108 mm print heads, staggered to produce a 320 mm wide print tape.

Two rows of print heads

The quadruple redundant nozzle has 5280 * 2 holes, which can effectively suppress the occurrence of defects ( more details can be downloaded in the QQ group )

HP thermal inkjet printheads have been used in a variety of printers. Each second, 630 million nanograms of adhesive can be dropped onto the powder bed to accurately determine the cross-section of the part . And the technology is two-way powder spreading, and the thickness of the powder layer is much higher than that of SLM, thereby further improving productivity.

However, if it is only due to two-way powder spreading and surface forming, it is far-fetched to claim that the production efficiency has increased by 50 times. After all , the slowness of SLM is slow in the point-by-point scanning and the long powder spreading process , while the slowness of the spray technology lies in the subsequent sintering process . But throughout the entire manufacturing process, SLM parts still need to be annealed, which is also very time-consuming. At the same time, if HP and desktop jet printers are compared together, the difference in efficiency between the two should still be reflected in the print head. In comparison, HP's jet technology has a higher manufacturing efficiency is no doubt, as for how much faster, just listen to 50 times .

material

In terms of materials, the powder used in the injection technology only needs injection molding specifications, does not require a wide particle size distribution (0.5 ~ 20μm), and can be nearly spherical, which also causes the cost of HP metal powder to be higher than that of SLM. The powder should be low . For specific reasons, please see Desktop Metal printing materials and product summary.

Part performance, accuracy and surface quality

Based on the laser-based SLM printing process, the parts have excellent printing accuracy and surface quality, and the performance research has also continued for 20 to 30 years, and has a good application foundation . As an emerging technology, jet technology currently has little research to support, and few cases are directly used in production.

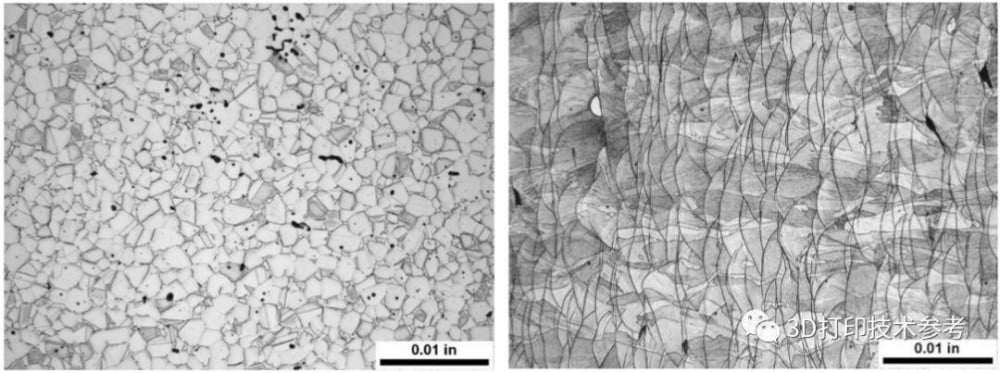

Two process grain structures: Metal Jet on the left, SLM on the right

It can be known that the parts formed by the jet technology will cause serious shrinkage during the post-sintering process, which is a major difficulty for the accuracy control of the parts; and the density of the parts may not be as good as SLM; an advantage over SLM printing is that jet printing The parts have good isotropy after sintering, and the performance of the former depends on the forming direction.

Volkswagen uses HP Metal Jet printed shift lever

Regardless of the molding method, the molded parts need to be machined and polished to meet the requirements of size and surface finish.

Equipment prices

The equipment of the laser-based SLM system is relatively expensive. Taking the EOS M300-4 as an example, depending on the configuration, the price ranges from US $ 810,000 to US $ 1.86 million, while the price of the HP metal machine is less than US $ 400,000. However, don't think that the HP brand is cheaper , because the following sintering furnace is also a large number (according to domestic easy-to-manufacture information, the price of the sintering furnace is higher than the price of its printer).

to sum up

The powder bonding molding process has received much attention since last year. It not only brings about an increase in manufacturing efficiency and a decrease in production costs, but also a new manufacturing method. However, which process is more cost-effective and more suitable for you depends on the specific application field. Don't blindly superstition HP, the one that suits you is the best.

For more manufacturing advantages of jet technology on SLM, please refer to the conclusion of "Technical Competition: Jet Technology is More Important than You Think".