Scientists from the National and Kapodistrian University of Athens have 3D printed a novel device that enables diabetics to monitor their blood sugar levels using only perspiration and a standard smartphone.

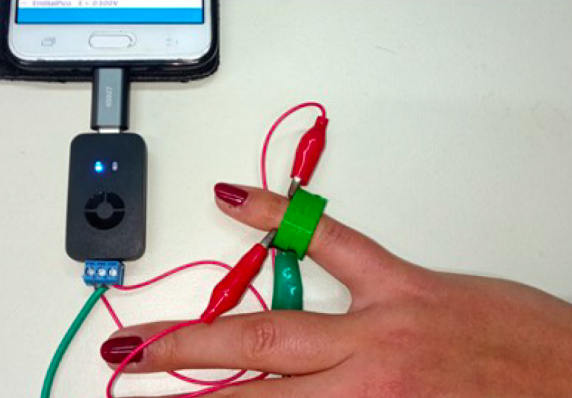

Leveraging a Flashforge Creator Pro 3D printer and conductive filament, the team was able to fabricate an electrochemical ring (or ‘e-ring’), featuring three plastic electrodes. Once connected to a mini-circuit board, the sensors proved capable of using biomarkers to precisely track a wearer’s glucose levels, providing them with a less-invasive self-testing alternative to the needles seen in regular glucometers.

Devising a less painful glucometer

For the estimated 34 million Americans living with diabetes, glucose monitoring is a reality of daily life, and the majority use enzymatic biosensors to keep track of their blood sugar levels. However, while such devices are accurate and easy to use at home, they often require the use of painful needles for sampling, which can discourage frequent testing.

For squeamish patients, the repercussions could be deadly, as infrequent testing potentially allows their glucose levels to get out of control. To avoid this, a number of less-invasive electrode-laden wearables have been developed in recent years, but these have proved inaccessible to most, due to their high production costs.

Additionally, many existing devices continue to rely on measuring patient enzyme levels, but these are dependent on factors such as temperature and pH that aren’t controllable in end-use situations. Sweat, on the other hand, includes a number of biomarkers that aren’t condition-dependent and indicate human health, thus the team opted to use perspiration as the basis for their novel glucometer.

3D printing the ‘e-ring’ monitor

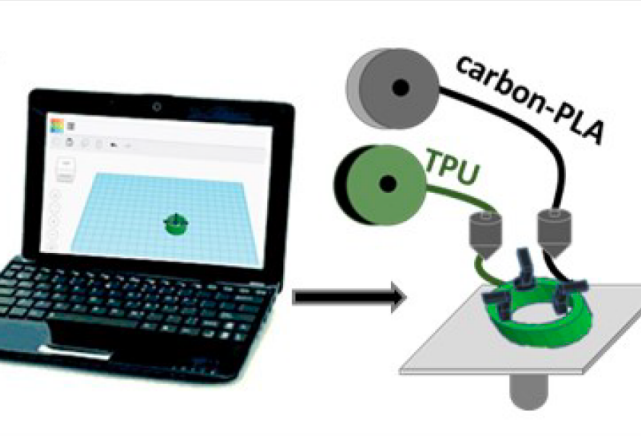

The scientists created their wearables using a commercial dual-extrusion 3D printer and TPU, with the aim of making them as accessible and flexible as possible. While they ultimately produced four different prototypes, each had the same basic layout: a green cylindrical structure with three carbon-based electrodes on their inside.

Once printed, the researchers electroplated their sensors in gold, enabling them to be connected via circuit board to a Samsung J5 smartphone, for the purpose of displaying glucose readings. In order to test their devices, the team then exposed them to a sugar-loaded ‘artificial sweat’ solution, and found that higher levels of gold coverage yielded readings with greater accuracy.

In later evaluations, a volunteer wore the e-ring before, during and after a meal, and the device picked up a significant increase in blood sugar levels just after eating. Around two hours later, the sensors detected the test subject’s glucose levels falling back to normal, proving its efficacy in converting sweaty biomarkers into readings.

Manufacturing on Demand

Although the e-ring demonstrated small deviations compared to the readings obtained from a standard glucometer, the Greek team maintained that these can be rectified via further R&D. In fact, the scientists are so confident in the precision of their device, that they believe their research paves the way for glucometers to be 3D printed in-house, both in lab settings and end-use scenarios such as hospitals.

Advances in additive wearables

3D printed wearable electronics have become a hot topic of research in recent years, and several of these projects have yielded devices with unique biological monitoring capabilities.

A team based at Clarkson University, for instance, have created UV-sensitive 3D printed biosensors, that change color when exposed to different levels of radiation. The devices are designed to be worn by those living in warmer climates, informing them when they’re potentially being over-exposed to the sun’s rays.

Researchers from Sungkyunkwan University have also fabricated biosensors with personalized health monitoring applications. Leveraging a commercially-available printhead and sugar-laden scaffold, the team were able to create accessible devices that proved capable of detecting changes in certain body strain signals.

Elsewhere, scientists from the University of Minnesota have demonstrated a novel method of 3D printing tiny wearable sensors. Using a customized Aerotech 3D printer, the team were able to create uniquely-conductive multi-layered materials, that could ultimately be printed directly onto the skin of volunteers.

The researchers’ findings are detailed in their paper titled “” The research was co-authored by Vassiliki Katseli, Anastasios Economou and Christos Kokkinos.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment