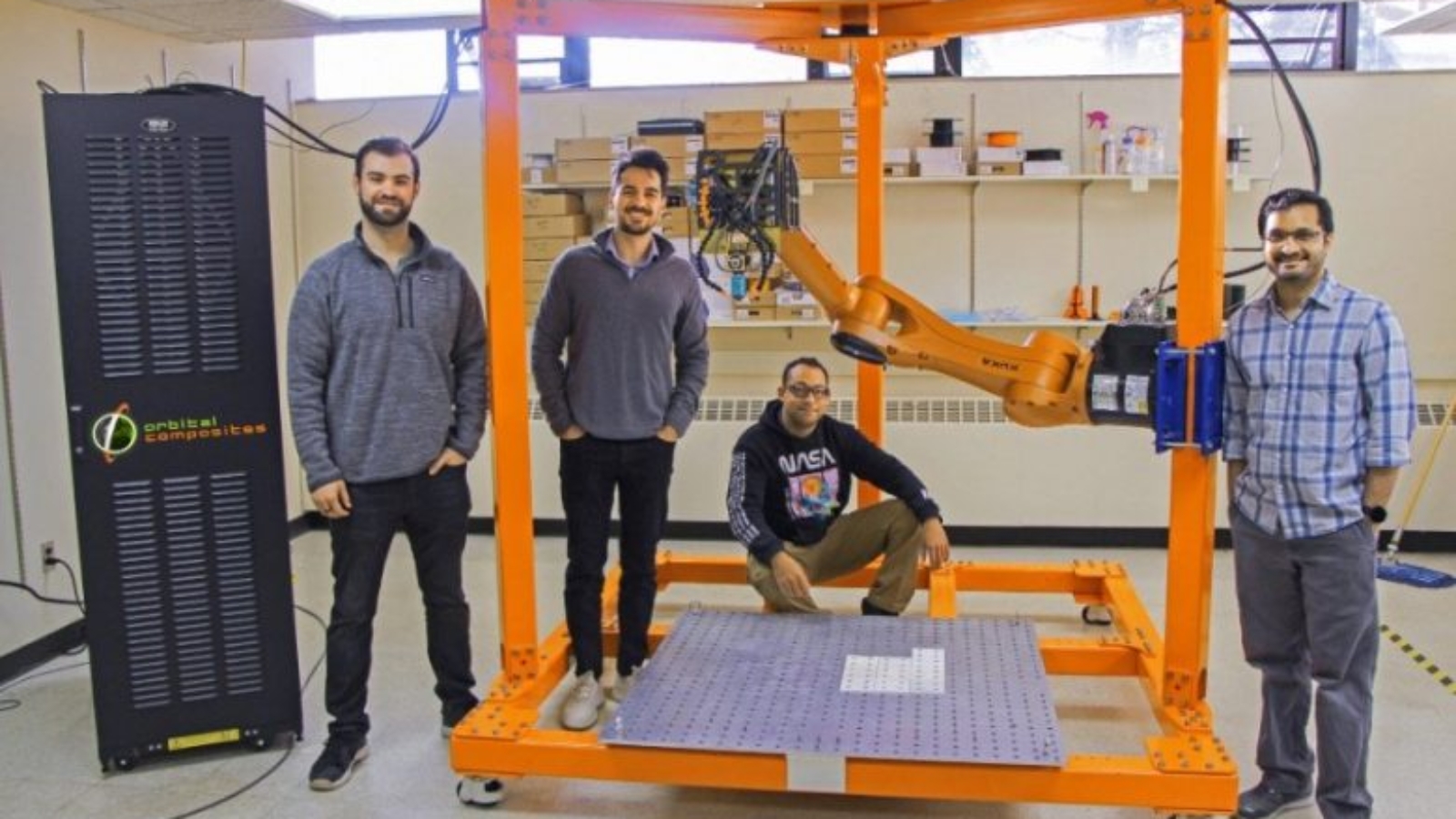

Orbital Composites has shipped its robotic 3D printer to the University of Minnesota Duluth (UMD). Orbital Composites’ commercially available Orbital S AM platform, will assist UMD in their polymer and composite additive manufacturing research, under the guidance of Dr. Gireesh Menta, professor of Mechanical Engineering at UMD. This marks a milestone for both parties as education about robotic 3D printing is gaining prominence in advanced manufacturing. UMD is expanding its teaching and research capabilities in large-scale, out-of-plane robotic 3D printing of thermoplastic polymers, by receiving its first robotic 3D printer. For Orbital, this is also their first commercial shipment of a turnkey robotic 3D printer.

Orbital S is a modular, robotic, additive, and subtractive manufacturing platform. It gives students a chance at hands-on learning of a variety of topics: robotics, software programming, material science, and, of course, 3D printing of polymer & composites. By learning to operate the robotic 3D printer, the students will receive interdisciplinary learning experience in mechanical and electrical design, chemistry, programming, as well as other subjects. This scalable platform also gives students the opportunity to learn about and use manufacturing equipment that can be used for both quick prototyping and high-volume end-use parts.

“Our team at the University of Minnesota – Duluth (UMD) is very excited to receive the Orbital S robotic 3D printer,” said Dr. Venkata Gireesh Menta. “It not only enables us to conduct research in this exciting next-generation manufacturing technology but also allows us to bring true interdisciplinary instruction to our classrooms. We expect this technology to improve UMD’s competitiveness in the Additive Manufacturing field and result in job opportunities with students gaining extremely valuable skills in robotics, AI, and additive manufacturing. We have many projects in mind and can’t wait to get started!”

The modular Orbital S platform provides students with a comprehensive overview with every process that goes into using a robotic additive and subtractive system. Students similarly express their enthusiasm to work with this technology throughout their collegiate journeys. “The arrival of the Orbital’s robotic 3D printer signifies UMD’s ambition to move forward with the never-ending march of technology, rather than stagnating in its wake” commented Ty Lindley, a graduate student at UMD.

Manufacturing on Demand

The Orbital S platform can print objects of virtually any shape and size, enabling research across many verticals, such as aerospace, biomedical, renewable energy, architecture, clean transportation, space, and many more. Giving soon-to-be young professionals access to such novel technologies Educating the future workforce about advanced manufacturing methods is a key component of Orbital’s mission for creating technologies for future generations.

Lindley believes this technology will not only have a positive impact on students’ learning experiences but the environment. “Incorporating sophisticated robotics and software into additive manufacturing opens up a brave new world with implications reaching as far as machine learning and AI, while reducing waste associated with manufacturing complex and strong parts. We are thrilled to be working with the Orbital S printer, and hope this next-generation machine helps reduce the impact to the environment associated with plastic, composite, and potentially metal manufacturing. The exposure to this technology is extremely valuable to me, and to anyone hoping to be competitive in markets involving engineering, innovation, and manufacturing.”

“We are innately passionate about educating the next generation of engineers and advance the research in robotic 3D printing”, said Cole Nielsen, Founder & CTO of Orbital Composites. “We see Orbital S platform as a perfect multidisciplinary teaching and research tool for Robotics, 3D Printing, Advanced Materials and Software development. As such, it is an essential tool for project-based learning for next-generation Mechanical, Civil, Electrical, Biomedical and Software engineers alike”.

“To ship, we also had to get our system UL certified”, concluded Amolak Badesha, co-founder and CEO of Orbital Composites. “We achieved UL safety certification for the Orbital S system, making us eligible to ship our system to every college, university, and national research lab in North America. Our goal is to get these robotic 3D printers in every university to educate the next-generation workforce trained in Robotics & Additive Manufacturing”.

You might also like:

What comes after binder jetting?: All the big players in the segment are working on it: Desktop Metal has developed advanced software for effective sintering and ExOne has introduced nano-particled binders. XJet has taken it all a step further by directly jetting the metal nanoparticles, further blurring the lines between binder jetting and material jetting. However, all these approaches still fall somewhat short and a new company, whose very name means change and evolution, is ready to introduce a new approach that will address all these issues through chemistry.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Victor Anusci

Leave A Comment