As part of the Artemis program, NASA is sending astronauts back to the moon, where we will prepare for human exploration of Mars. Additive manufacturing or 3D printing technology from experts from NASA, industry, and academia is a pioneering method of printing rocket parts that can power these journeys.

NASA’s Rapid Analysis and Manufacturing Advancement Technology Project (RAMPT) is advancing the development of additive manufacturing technology for 3D printed rocket engine parts using metal powder and lasers. This method is called blown powder directed energy deposition method, which can reduce the cost and delivery time of producing large and complex engine components (such as nozzles and combustion chambers). Previous developments in additive manufacturing did not have the large-scale capabilities offered by this emerging technology.

“This technology advancement is significant, as it allows us to produce the most difficult and expensive rocket engine parts for a lower price tag than in the past,” said Drew Hope, manager of NASA’s Game Changing Development Program, which funds the RAMPT project. “Further, it will allow companies within and outside of the aerospace industry to do the same and apply this manufacturing technology to the medical, transportation, and infrastructure industries.”

Credits: NASA

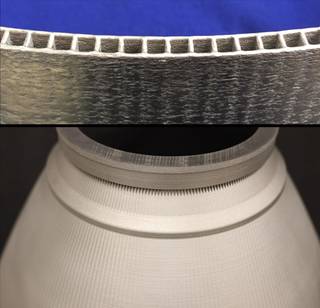

The printing method is to inject metal powder into a molten metal pool or molten pool heated by a laser. The powder nozzle and laser optics are integrated in the print head. The print head is mounted on the robot and moves in a pattern determined by the computer one layer at a time. This manufacturing method has many advantages, including the ability to produce very large parts-only limited by the size of the room in which they are manufactured. It can also be used to print very complex parts, including engine nozzles with internal coolant channels. Rocket engine nozzles containing internal coolant passages allow cryogenic propellant to pass through the passages to help keep the nozzles at a safe temperature.

“It’s a challenging process to manufacture the nozzles traditionally, and it can take a very long time,” said Paul Gradl, RAMPT co-principal investigator at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “Blown powder directed energy deposition additive manufacturing allows us to create very large-scale components with complex internal features that were not previously possible. We’re able to significantly reduce the time and the cost associated with the fabrication of channel-cooled nozzles and other critical rocket components.”

The RAMPT team recently used this technology to produce one of the largest nozzles printed by NASA, with a diameter of 40 inches and a height of 38 inches, with a fully integrated cooling channel. The manufacturing time of the nozzle has reached a record level (compared with the traditional welding method, it took nearly a year and only 30 days). Due to the rapid development of technology, the completion time was one year earlier than planned.

The success of the RAMPT project attracted the attention of NASA’s Space Launch System (SLS) Rocket Team. NASA’s SLS and Orion spacecraft are the backbone of our deep space exploration program, which includes sending the first woman and second man to the moon in 2024 and establishing a sustainable exploration system by the end of the decade. The SLS program is investing in RAMPT’s blown powder directed energy deposition manufacturing process with the aim of certifying it for aerospace. The team used the technology with RAMPT to build and evaluate tunnel cooling nozzles no more than 5 feet in diameter and nearly 7 feet high.

Johnny Heflin, SLS Project Liquid Engine Office Manager, said: “Using this new type of additive manufacturing technology to produce channel wall nozzles and other components will allow us to manufacture SLS engines at the required scale, reducing schedules and reducing costs.”

Credits: NASA

Through a series of rigorous heat tests, engineers will make a small-scale nozzle withstand the same 6,000-degree combustion temperature and continuous pressure faced during the launch process to prove the durability and performance of the new directional energy deposition technology.

Public-private partnership

While NASA is leading the technology development expedition, partnerships with academia and industry play an important role. Through an agreement with Auburn University in Alabama, RAMPT has partnered with specialized manufacturing companies that have advanced “state-of-the-art technology” to support their work and make the technology developed by the team widely available to the private sector . Because partners share some of the development costs, these public-private partnerships also add value to NASA missions.

NASA’s investment in powder blown direct energy deposition manufacturing technology and material development will play a key role in realizing the agency’s most ambitious exploration mission. The technology may also play a key role in many other industries (including commercial spaces), helping to make the world a better place to place one print at a time.

The RAMPT project is funded by NASA’s “Game Change Development” program within the Space Technology Mission Bureau. RAMPT includes partners from across the organization, including NASA’s Glenn Research Center in Cleveland, NASA’s Ames Research Center in Silicon Valley, California, industry and academia.