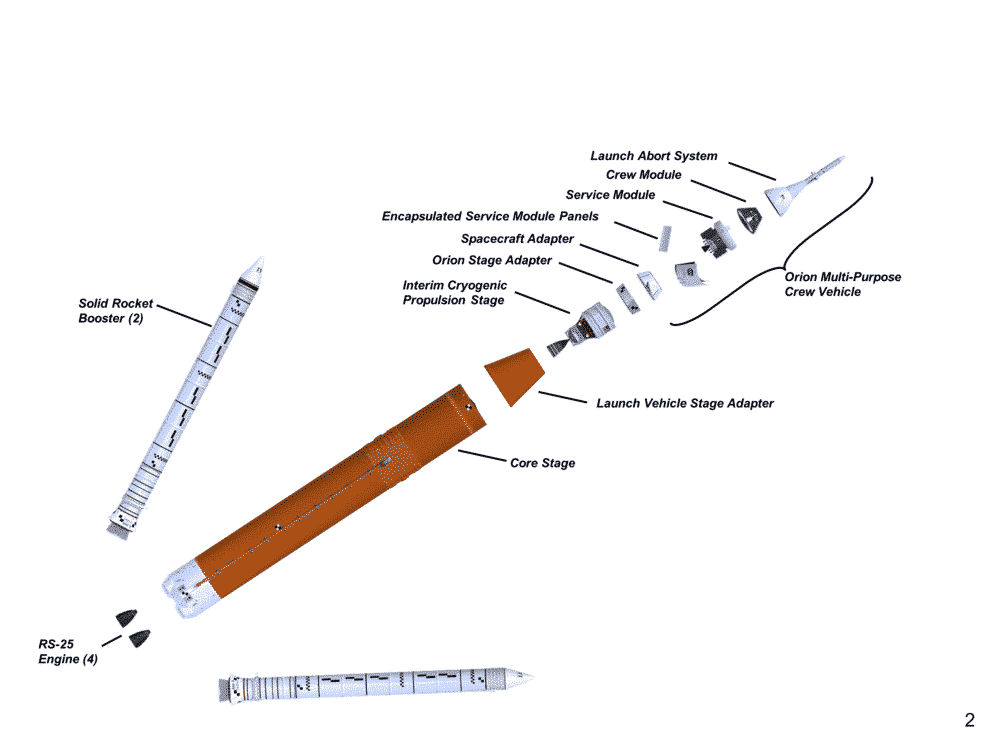

During the first launch, NASA’s Unmanned Space Launch System (SLS) giant rocket will fly around the moon as part of the initial test flight of the Artemis 1 mission. This will mark the beginning of one of the most talked-about space programs this year. Artemis is an ongoing government-funded manned spaceflight program whose goal is to bring the first woman and the next man to the moon by 2024, particularly, on the lunar south pole region. SLS is the most powerful rocket ever manufactured, powered by four super engines, which are designed to handle some of the most extreme temperatures, as they move large amounts of propellant to produce enough energy to allow the rocket to escape the gravity of the earth.

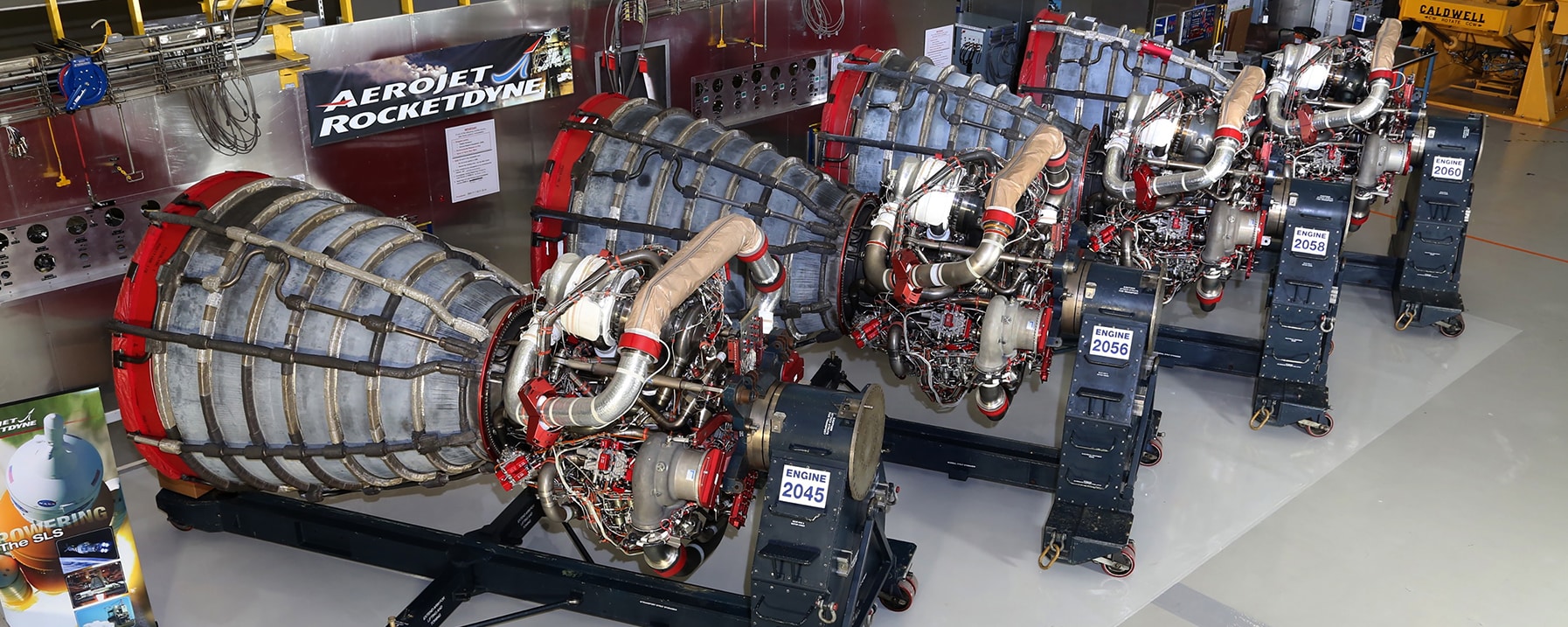

As part of a long-term partnership with NASA, Aerojet Rocketdyne of Sacramento, California, will manufacture a total of 24 RS-25 rocket engines to support up to 6 SLS flights, with a total contract value of nearly $3.5 billion. The company initially planned to produce six new RS-25 engines and recently received a $1.79 billion contract modification contract to manufacture 18 additional RS-25 rocket engines to support future deep space exploration missions.

“This contract allows NASA to work with Aerojet Rocketdyne to build the rocket engines needed for future missions,” said John Honeycutt, the SLS program manager at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “The same reliable engines that launched more than 100 space shuttle missions have been modified to be even more powerful to launch the next astronauts who will set foot on the lunar surface during the Artemis missions.”

Although the Space Shuttle Endeavour is now in the museum exhibit at the California Science Center in Los Angeles, its engines and the engines used to power the Discovery and Atlantis have been maintained by SLS. However, unlike the space shuttle, SLS will not reuse its engine. Once the core phase disappears about eight minutes after launch, the engine will decompose during the return process. Currently, there are 16 RS-25 engines remaining in NASA’s space shuttle program. Aerojet Rocketdyne has upgraded, tested, and prepared to support the first four SLS missions. However, as more SLS missions are expected to begin at the end of this century, Aerojet Rocketdyne is required to build more engines. In fact, six new consumable RS-25 engines have been assembled using advanced manufacturing technology, including 3D printing, thereby reducing the cost and time to manufacture each engine.

The additional 18 engines will continue to utilize the optimization of the supply chain, combined with the additive manufacturing (AM) technology that has been introduced in the initial production of the SLS engine.

Using AM technology to reduce costs and improve engine efficiency is a top priority for aerospace and defense companies. Alan Fung, a senior engineer in Aerojet Rocketdyne’s additive manufacturing team, told 3DPrint.com that hundreds of people have been designing, developing, and manufacturing engines that rely primarily on laser powder bed fusion technology for at least additive manufacturing. There are 35 parts on each engine.

“Our primary focus is to make reliable, robust printed parts, that will work 100 percent of the time. We started designing some of these pieces a couple of years ago to make sure they were tested and certified for NASA’s space program, which is crucial to the safety of the upcoming crewed missions,” said Fung.

With the delivery of these new engines scheduled to begin in 2023, the fleet will not waste any time. Fung said: “One of the main tasks of the first round is to work closely with NASA to develop certification procedures.” It is revealed that “we now have a process for manufacturing parts using safe and known additives, which is what we need to ensure The necessary conditions for parts to work properly on engines that power future SLS missions.”

3D printing simplifies the production of multiple RS-25 parts and components, lowers the production cost of the engine, and improves reliability. When there are fewer parts welds, the structural integrity of the engine will be improved. This is a very manual and complicated manufacturing process. In fact, the manufacture of rocket engines is so complicated that only a few countries can manufacture them.

“That’s where AM really shined for us. We were able to get rid of many welding joints and just incorporate the processes automatically, getting down the part count and reducing the load across the engine,” said Fung.

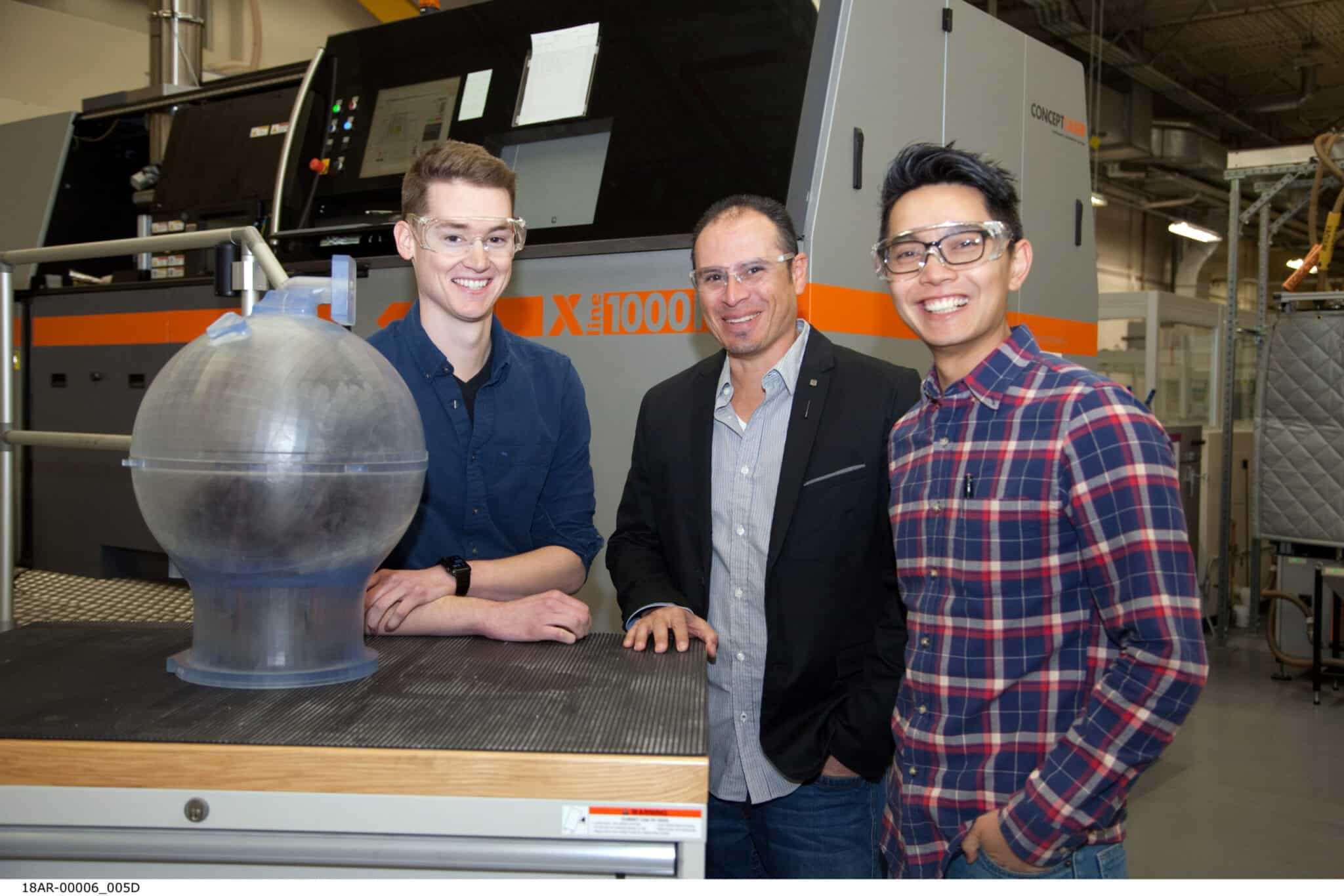

One of the largest 3D printed components on the engine is the key “Pogo” accumulator component. The complex hardware is about the size of a beach ball and can be used as a shock absorber to reduce the vibration caused by the propellant flowing between the vehicle and the engine. Fung described the 3D printed component as a key part of the engine because it helps to smooth the astronauts and vehicles and ensure a safe flight. In addition, he explained that Pogo used to require more than 100 welding points in the past. These welding points have to be completed manually and took nearly four years. The 3D printed Pogo developed at the Aerojet Rocketdyne plant in Los Angeles reduced welding to only third. And completed in less than a year.

Some of these modified components have been tested during engine tests that replicate flight conditions. For example, in a 400-second test conducted by NASA’s Stennis Space Center, Aerojet Rocketdyne was able to successfully evaluate the performance of 3D printed Pogo battery components.

“We expect that more and more engines will be additively manufactured in the future, leaving behind a lot of traditional rocket engine manufacturing processes that are very difficult, and allowing us to print more engines. Eventually, the time to build is going to go down even more, especially as the industry gears towards incorporating more lasers and bigger machines; which is good for us, because our engines keep getting a little bit bigger than the last ones. So, when those machines get to be bigger, use more lasers, and print parts faster, then that’s when we will see a really big shift in the way we make rocket engines,” went on Fung.

In cooperation with NASA, Aerojet implemented a plan to reduce future engine costs by more than 30% compared to the version on the spacecraft, thanks to advanced manufacturing technologies such as AM, and engineers modified some rocket components.

During the flight, these four engines will provide SLS with approximately 2 million pounds of thrust to send heavy rockets into space. The rocket engine is mounted on the bottom of a 212-foot-high core platform that can hold 700,000 gallons of propellant and provides a flight computer to control the rocket flight.

Aerojet’s AM team is using GE Concept Laser and EOS machines to meet the requirements of selective laser melting. Fung said they use superalloys, mainly nickel-based alloys, for 3D printed engine parts because of its excellent corrosion resistance, high strength, and resistance to hydrogen fuel in most Aerojet Rocketdyne liquid propellant rocket engines The resulting hydrogen embrittlement.

These new RS-25 engines are upgraded versions of the space shuttle engine, and the space shuttle engine is already the most reliable engine in history. It took engineers 40 years to make the reciprocating engine as reliable, safe, and high-performance as possible. But we believe that through additive manufacturing, we can also try to reduce costs. This technology will completely change the way we build engines”

Faced with so many challenges, having a certified rocket engine brings the next lunar explorer into orbit, like a stepping stone to progress. After all, the SLS rocket is the backbone of NASA’s deep space exploration, and it will prepare for human long-term space travel and the ultimate Mars journey.