Medical device supplier rms company has added a 3D Systems DMP Flex 350 Dual 3D printer to the more than 30-machine-strong print farm at its 3D printing complex.

Through its facility, rms offers medical OEMs complete ‘Powder to Package’ services, which allow them to go from a digital file to a sterilized, packaged final product. By expanding its capabilities with a DMP Flex 350, the firm anticipates being able to not only produce new types of implants but “accelerate throughput” across the board.

“rms company decided to invest in a DMP Flex 350 Dual [because] it is engineered in a way that allows us to produce the high precision, high-quality products we expect from our current installation of DMP systems without changing the processing parameters we validated when we initially developed our AM capabilities,” explains Ryan Kircher, a senior additive manufacturing engineer at rms company. “This [also] allows us to explore not only new products but reduce production times and costs.”

3D Systems’ DMP Flex 350 systems

Unveiled back in 2018, 3D Systems’ DMP Flex 350 machines are designed to enable the high-throughput, low-cost, and repeatable production of high-quality parts from challenging alloys. Compared to their predecessor, the ProX DMP 320, the 3D printers feature a new integrated Powder Management Unit (PMU), to ensure consistent part quality, and boast a 15% overall productivity boost.

Both the single-laser and dual-laser versions of the DMP Flex 350 also ship with a unique vacuum chamber concept that drives down users’ argon gas consumption and allows them to achieve high oxygen purity (<25 ppm). As a result, the systems are said to maximize the amount of powder that can be reused and allow for the production of extremely strong parts with high chemical purity.

When resulting parts undergo hot isostatic pressing, they’re even said to be of comparable quality to forged parts, something that could lend them aerospace use cases. That said, 3D Systems doesn’t just market the machine as a tool for producing end-use aerospace parts. Rather, the firm says its system can address user needs ranging from R&D and application development to serial production, in any area where custom lightweight metal parts are needed.

rms’ Powder to Package offering

rms company prides itself on being one of the largest contract manufacturers of high-quality, tight-tolerance medical devices in the world. Through its Powder to Package offering, the firm produces precision machined components and assemblies at prototype, pre-production, and post-launch volumes, for builds such as pacemakers and endoscopy devices.

Manufacturing on Demand

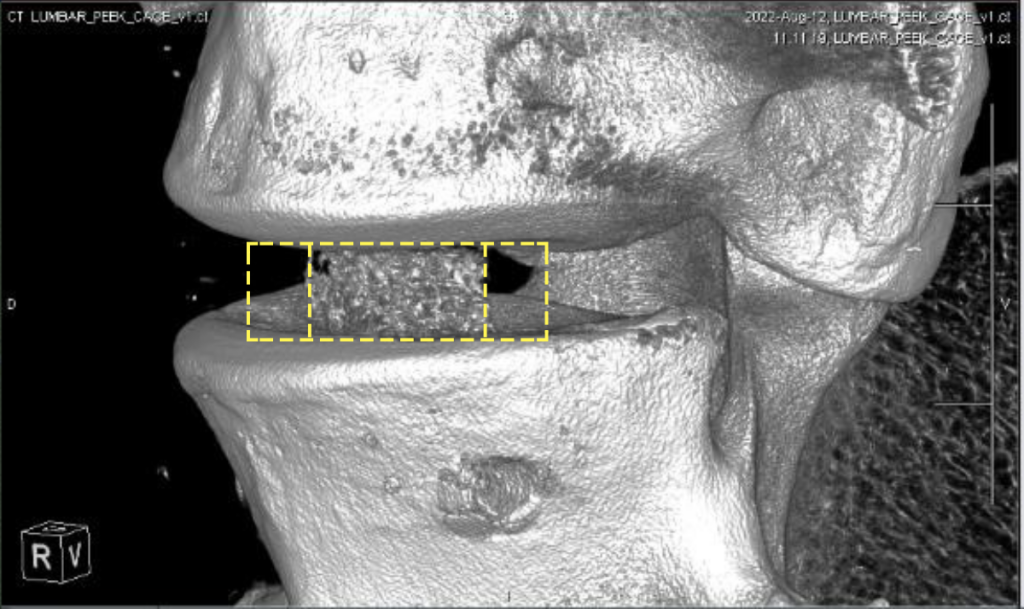

Over the last four years, 3D Systems has helped rms company expand the metal 3D printing behind its services, from just a single system to more than 30. While this has already allowed the business to establish itself a strong reputation as a manufacturer of high-quality titanium implants, adopting the DMP Flex 350 is expected to enable an increase of up to 50% in its small implant throughput.

The company’s engineers also believe these productivity gains will open new opportunities in the production of large joint and extremity implants, which were previously economically challenging with a single laser system. What’s more, the firm says realizing the benefits of installing the DMP Flex 350 hasn’t required any parameter tuning, so expanding its capacity has been a seamless process.

“Uptime on these machines is crucial for us to maintain our customer commitments,” adds Troy Olson, director of operations in rms company’s additive manufacturing division. “Our printers operate on a 24/7 production cadence, which leaves little room for downtime. During our validation process, the DMP Flex 350 Dual showed no measurable differences in mechanical properties or dimensional accuracy. We are excited to add this new capability to our existing printing operation.”

“As we continue to scale our additive manufacturing business, the 3D Systems DMP Flex 350 Dual will be at the forefront of our growth strategy.”

Additive manufacturing continues to gain popularity among medical OEMs as a means of producing customized surgical implants. Late last year, Bond3D and Invibio Biomaterial Solutions unveiled a technology for the 3D printing of next-generation spinal cages, which enables them to be configured in a way that accelerates patient recovery.

Likewise, 3D printed maxillofacial implants by the likes of Cerhum have come on leaps and bounds in recent years. Not long after its MyBone medical devices gained approval for use in patients throughout Europe, Cerhum’s technology was also deployed at the Claudius Regaud Institute and Toulouse University Hospital, as part of an operation that saw a cancer patient treated with a 3D bioprinted nose.

You might also like:

Regenerative Medicine strategy and tissue bioprinting plans announced by 3D Systems: Since being appointed CEO, Dr. Jeffrey Graves has clearly defined his vision for 3D Systems to lead in the medical vertical. On an earnings call last year, Graves singled out medical 3D printing for “patient solutions” as an “increasingly exciting market” where 3D Systems is “a clear leader.” Graves continued with optimism when he unveiled the new tissue program, claiming that 3D Systems development of “patient-specific human tissues” will “dramatically alter how patient care is delivered.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment