Today, medical treatment has come a long way, and various new technologies are constantly enriching medical products and bringing the true gospel to patients. 3D printing, as a new technology that has been widely recognized in recent years, has also made important contributions to helping medical care.

However, after all, 3D printing and medical care belong to two “independent” industries. 3D printing practitioners are actively exploring the application of technology, and medical personnel are also paying close attention to the possibility of the application of existing new technologies, plus two The professionalism of the technology is very high, only the personnel of the two parties can collide and spark when they communicate closely. As the application of medical 3D printing becomes more and more extensive, we can see that medical staff will actively seek the help of 3D printing, which provides an opportunity for 3D printing to play a greater role, and related medical cooperation continues to take place.

Innovative cooperation

Recently, the Atlanta Children’s Health Company launched Georgia’s first surgery to place a 3D printed tracheal stent on pediatric patients in August this year. The cross-functional team of pediatric surgeons used three custom stents printed by biomedical engineers at Georgia Institute of Technology to complete an airway obstruction operation for a 7-month-old baby. It is worth noting that the personnel of both parties has done an innovative experiment this time.

The person in charge of the hospital said that the combination of children’s clinical expertise and bioengineering research can provide more effective clinical care and find innovative and life-saving treatment options for patients, which is crucial for the future of Georgian pediatric care.

In this case, patient Amir suffered from congenital tracheal softening. The trachea collapsed to varying degrees due to the lack of proper cartilage stiffness and support of the trachea. During Amir’s hospitalization in the pediatric intensive care unit, airway collapse often occurred, which could not be corrected by conventional surgical methods. With this in mind, the clinical team recommended surgical insertion of an experimental 3D printed tracheal stent to open his airway and further expand the trachea and bronchus.

The tracheal stent used is a new device still under development, designed by Scott Hollister, the head of the joint program of Georgia Institute of Technology and Atlanta Children’s Healthcare. Hollister said: “The possibility of using 3D printing technology to save the lives of children is our daily motivation in the laboratory, and we are determined to develop innovative solutions to meet the needs of Georgia’s most complex pediatric patients.”

Complex surgery and 3D printed tracheal stent

Hollister is also the director of the 3D Medical Manufacturing Center of Georgia Institute of Technology. His team produced multiple versions of stents in various sizes to ensure that the surgical team placed the stent in the right place during the surgery and perfectly fit the patient’s airway and its surroundings. The bracket is printed with polycaprolactone (PLC) powder by the SLS process.

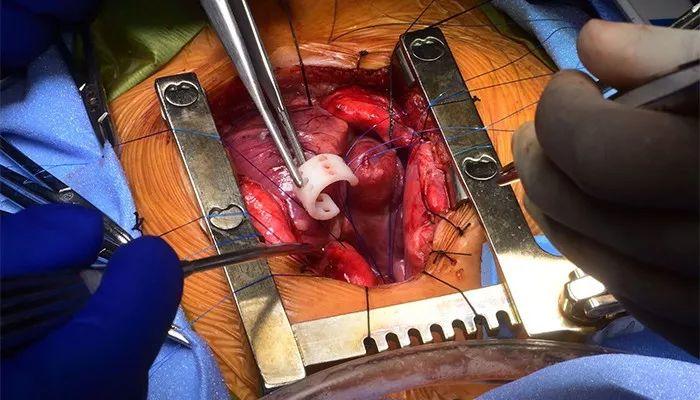

In this complex 10-hour operation, a team of children ’s cross-functional surgeons successfully placed three 3D printed stents around the patient ’s trachea on August 17. In the next 3-4 years, the material of the stent will be absorbed to allow the expansion of the trachea and bronchi.

Expand Case

At present, there have been more than a dozen cases of using 3D printing to make stents to treat bronchial softening. The earliest began in 2013.

Kaiba Gionfriddo, a 6-week-old boy born in Ohio, USA, was unable to breathe spontaneously in 2012. He was diagnosed with extremely rare congenital tracheobronchial softening and face daily death threats. The University of Michigan School of Medicine used 3D printing to make a tracheal stent implanted in the body based on CT images. After 7 days, it evacuated from the ventilator and spontaneously breathed. This is the world’s first 3D printed tracheal stent for clinical use.

In China, in 2016, Tangdu Hospital and Xi’an Jiaotong University cooperated to complete a case of tracheal softening trachea 3D printed external stent suspension surgery. The patient’s trachea softened up to 6 cm, the narrowest part was only 3 mm, and the length of the softened segment reached the limit of tracheal resection, resulting in severe dyspnea and life-threatening. The 3D printed tracheal stent is placed around the softened trachea and fixed, so that the collapsed trachea is propped up by the outer stent, and the narrow airway is unclogged again, so that the patient avoids long tracheal resection and becomes the treatment of trachea Effective method. It is worth noting that the biodegradable stent is still used for this stent.

Risk and opportunity

These cases are very exciting from an engineering perspective, but from a medical and biological point of view, there are still many problems facing verification, such as the mechanism of action of tracheal tissue and degradable stents and the stents they bring Structural design issues, which design will have a better effect, whether the trachea still has the risk of collapse after the degradation of the stent is completed, how the material degradation cycle is, and so on. In addition, this technology is also facing costs and medical licensing issues.

End

In any case, 3D printing is gaining more and more approval in surgical practice, including innovations in surgical technology. If more design matters and choices can be clearly understood by surgeons, then more interesting progress in this direction will be seen in the future.

At the same time, for 3D printing practitioners, these printed parts are just models, and the pure model does not make any sense to us, but through cross-domain cooperation, it is used where it should be, and its value is only Will be reflected.