Mark One, an Italian company that creates customizable professional 3D printers, and the Provec Kawasaki Racing Team (KRT) have renewed their technical partnership for the 2022 WorldSBK racing season. The KRT currently leads the field with more than 500 podium finishes, thanks to the efforts of six-time World Superbike champion Jonathan Rea and teammate Alex Lowes.

The fast-paced and ever-changing nature of the racing world requires teams to regularly design, test, and update their methods and applications. In order to keep up with these demands, the KRT has incorporated Mark One’s innovative 3D printing technology into its production process. This allows the riders and crew to quickly transform ideas into components and sets them on a path toward achieving their goals.

The fast-paced and ever-changing nature of the racing world requires teams to regularly design, test, and update their methods and applications. In order to keep up with these demands, the KRT has incorporated Mark One’s innovative 3D printing technology into its production process. This allows the riders and crew to quickly transform ideas into components and sets them on a path toward achieving their goals.

Mark One’s collaboration with the KRT began in 2018 after the team expressed interest in adopting additive technology in order to revolutionize its production cycle and create new high-performance components. Upon acquiring two of Mark One’s ONE printers, the KRT saved 85% in production times and costs.

Following these results, the KRT decided to obtain a third printer for the 2022 racing season. Mark One supplied the team with the new MK One system, which was placed in its workshop in Barcelona. KRT currently keeps the other two ONE systems in its racing box.

Manufacturing on Demand

Mark One’s extrusion 3D printing technology has allowed the KRT to consistently perform at the highest level, without compromising on quality. The company’s 3D printers enabled the team to create customized components, reduce production times, and guarantee users simplicity of use.

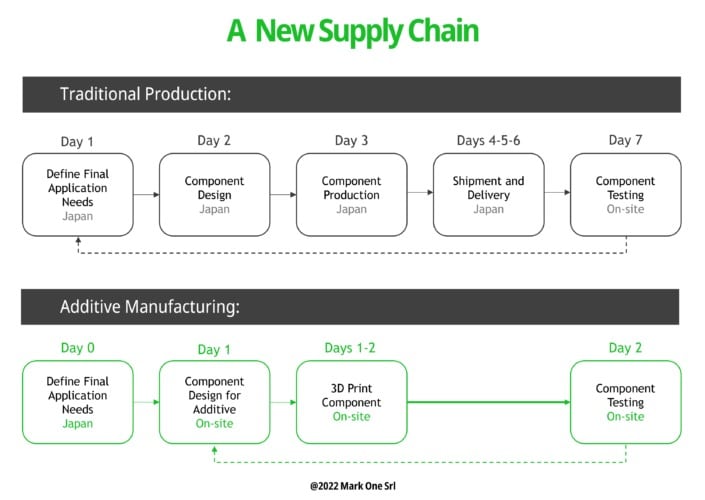

The renewal of Mark One and the Kawasaki Racing Team’s technical partnership for the 2022 racing season represents an opportunity for the SBK team to explore further the benefits of additive technology. As the graphic on the side shows, KRT’s supply chain has been significantly simplified, meaning they can currently test many components within just a few days.

The renewal of Mark One and the Kawasaki Racing Team’s technical partnership for the 2022 racing season represents an opportunity for the SBK team to explore further the benefits of additive technology. As the graphic on the side shows, KRT’s supply chain has been significantly simplified, meaning they can currently test many components within just a few days.

Mark One’s 3D printers ensure better control of the entire production process, thanks to their simplicity of use and this means that the KRT is able to actively manage each stage of the printing process and guarantee the production of complex and high-performance components, without having to rely upon external suppliers. In this way, the KRT has managed to cut a phase of the traditional supply chain that led to long lead times.

This change was essential for the KRT’s technical crew, who is required to carry out rapid component prototyping for the team’s riders throughout the racing season. Once these prototypes are ready, they are printed and immediately tested by the KRT’s riders. The testing phase allows both the riders and the crew to fine-tune the components so that they appropriately address the issues at hand. In the case that adjustments need to be made, the KRT can simply use Mark One’s 3D printers to reprint the component.

You might also like:

Tesla enthusiast runs 90-printer farm to make SnapPlate holders: The SnapPlate removable front license plate mounts are made to install and completely remove in seconds. The clean, minimal design blends perfectly with the front end when it’s installed and leaves no unsightly hardware behind when it’s removed. Users can choose from pre-configured assemblies with USA, Canada and Mexico plate mounts or configure a custom SnapPlate for other countries.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment