3D printed ophthalmic lens specialist Luxexcel has announced that its proprietary 3D printing technology for optical lenses has advanced from the pilot phase to the printing of commercial lenses.

Based in the Netherlands, the company has reached a stage where its technology is able to ship commercial lenses to customers on a daily basis. It has had 5000 lenses printed on several of its ISO-certified VisionPlatforms™ installed in USA and Europe over the past 12 months.

Previously Luxexcel had raised $13.9 million in series C funding, announcing that it was moving into its “next phase” of development. Now having moved past that pilot phase, Fabio Esposito, CEO of Luxexcel, says that “By achieving this level of maturity we are ready to further grow the incredible potential of this technology and develop unique lenses both in ophthalmic and in smart eyewear.”

“3D printing is uniquely positioned to bridge the gap between traditional lenses and the future of eyewear which resides in smart functionalities.”

The Luxexcel VisionPlatform™ for 3D printed lenses

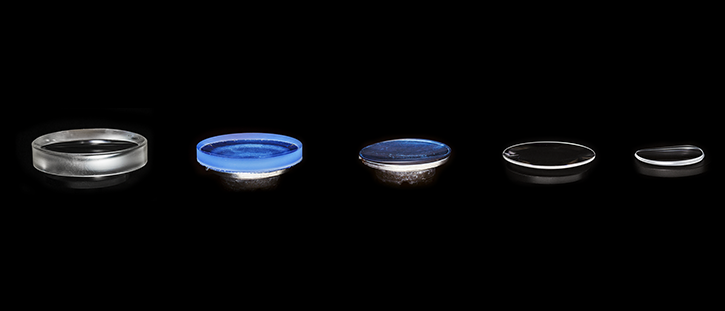

Developed in 2009, Luxexcel’s 3D printing technology is an additive manufacturing process for developing functional lenses. The technology helps to combat the waste produced by traditional ophthalmic lens fabrication methods.

The conventional process for manufacturing custom optical lenses involves multiple machining steps in which material is subtracted from a lens blank through grinding, polishing, and edging. In this process around 80% of the material is wasted. It is also a low yield and labor intensive approach.

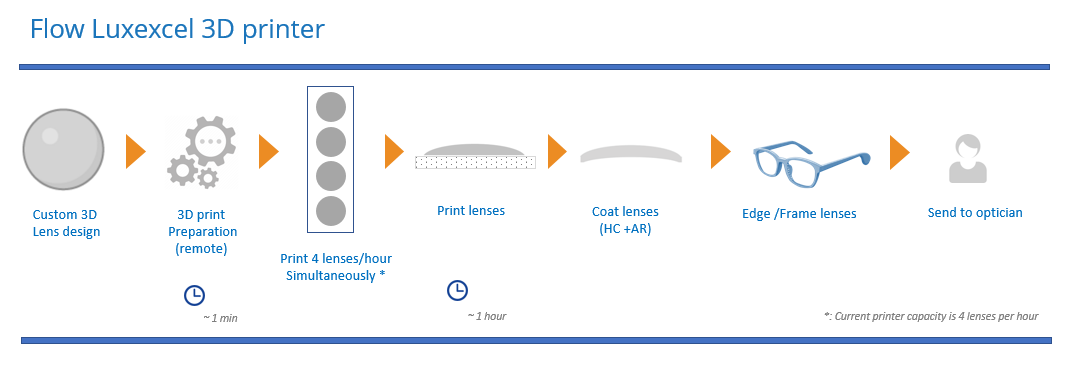

Luxexcel’s alternative process begins with the custom lens design and surface prescription being prepared in Luxexcel’s VisionMaster™ Software for printing. Luxexcel’s liquid material called VisionClear™ is then loaded into the VisionEngine™ 3D printer, which manufactures lenses by jetting tiny droplets of a UV-curable resin onto the substrate and curing it with UV-light. This solution is able to produce custom lenses at volume, with less material wastage.

The process is all comprised onto Luxexcel’s VisionPlatform™. It consists of industrial-grade 3D printers, lens-design software and workflow integration tools. This enables customers to manufacture 3D printed ophthalmic quality lenses which meet industry standards including all ANSI, ISO & FDA requirements, in a “single step” process.

“We have developed this solution to bring to the eyewear market an amazing capability: 3D printed lenses. In the past 12 months, Luxexcel focused on the industrialization of the VisionPlatform™ in collaboration with key manufacturers in the ophthalmic field,” commented Guido Groet, Chief Commercial Officer of Luxexcel.

Manufacturing on Demand

“The Luxexcel VisionPlatform™ brings a unique solution to the world of eyewear and enables the addition of prescription to smart eyewear.”

3D printed optical lenses

Luxexcel’s objective is to ‘change the way ophthalmic lenses are made’ by collaborating with independent optical labs to provide new production tools and create unique new eyeglasses for the ophthalmic industry.

Luxexcel are not alone in having utilized 3D printing to develop optical lenses, however. Dr. Song Hongxin, an ophthalmologist and researcher at the Beijing Tongren Hospital, China, has 3D printed optical lenses to help treat patients with keratoconus, an eye disease that deforms the cornea.

Northwestern’s McCormick School of Engineering has developed a method for 3D printing high quality lenses for use in optical imaging devices. Applications of the technology include customized contact lenses or smartphone lens attachments.

MSc applied psychology student Logan Williams, from the University of Canterbury in New Zealand, has also invented a set of 3D printed “Polar Optics” contact lenses. The 3D printed lenses have the potential to protect sufferers of photosensitive epilepsy from seizures.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Anas Essop

Leave A Comment