Netherlands-based Luxexcel is a pioneer of 3D printed lenses. The company’s proprietary technology—first developed over a decade ago—stands on a strong foundation of optic, material, process and, of course, 3D printing expertise. Today, Luxexcel remains the only company to have developed a 3D printing process for creating prescription lenses.

Despite having carved out its own niche in the ophthalmic lenses market, the innovative company is also forging new avenues for its 3D printing technology. Recently, the company has made something of a smart decision—pardon the pun—by making inroads into the smart glasses segment. Though smartglasses have faced hurdles in terms of their adoption, Luxexcel’s 3D printing is uniquely positioned to enable technology companies to make the wearable devices viable for a broader consumer market.

To learn more about this opportunity and illuminate how Luxexcel’s technology fits into the emerging smart glasses trend, we caught up with Luxexcel CEO Fabio Esposito.

The Luxexcel VisionPlatform

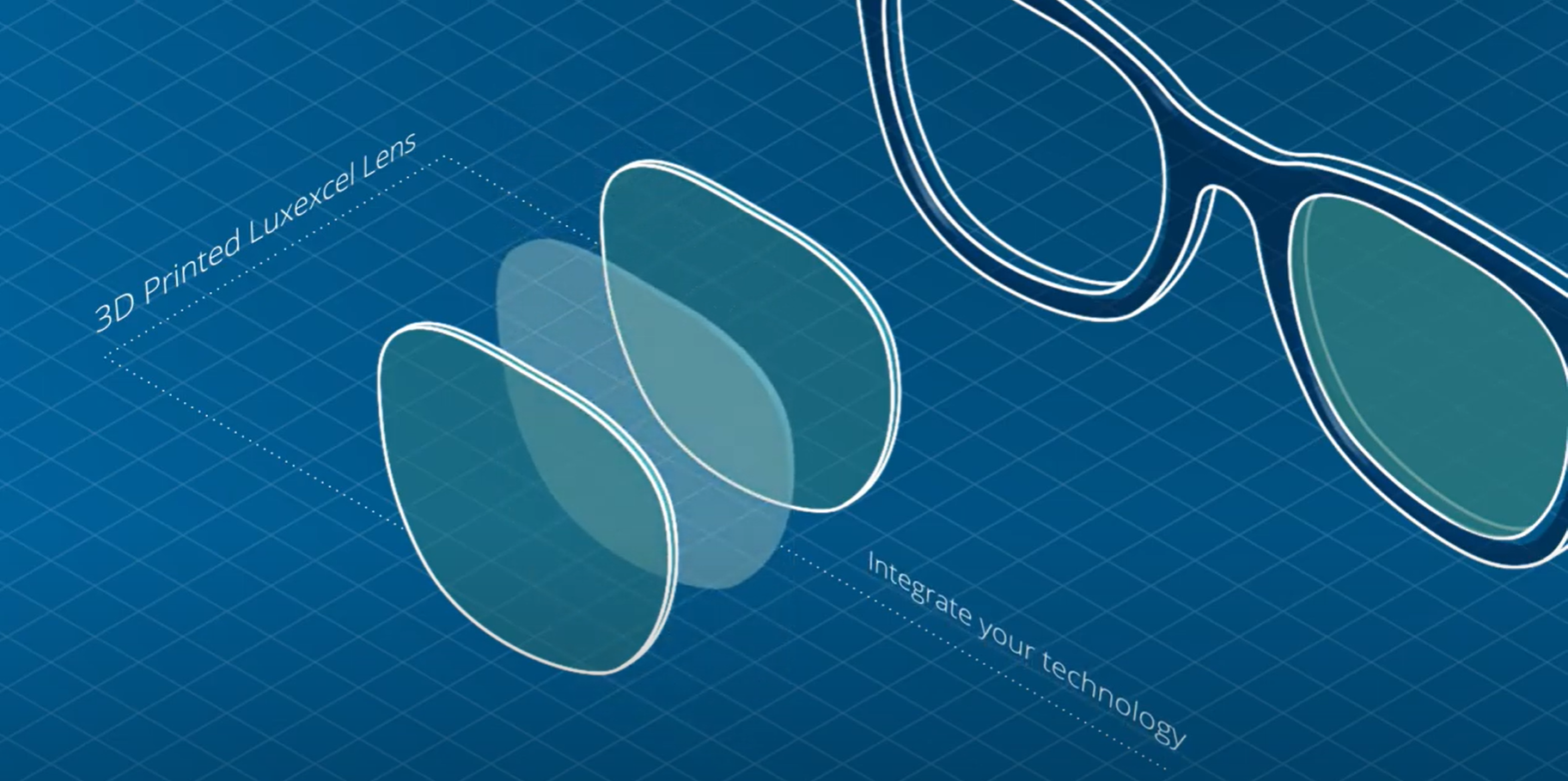

Before focusing on how Luxexcel has the potential to breathe new life into the smartglasses market, we have to first look at the company’s technology. The VisionPlatform™ is Luxexcel’s turnkey solution for 3D printing ophthalmic lenses, and comprises hardware, software and proprietary materials.

“Luxexcel has developed a unique 3D printing technology to manufacture lenses for eyewear and smart glasses,” Esposito says. “The technology, based on proprietary printer hardware, software, process and ink materials, provides a complete solution for printing lenses, adding prescriptions and integrating smart functionalities.”

The 3D printer itself is an inkjet-based system that is capable of producing lenses without the need for supports or any post-processing. As Esposito explains, the printed lenses can simply be “snapped into a frame once printing is complete.”

Materials and software are the other puzzle pieces. “The proprietary consumable material—Luxexcel VisionClear™—has been formulated to create transparent objects, ideal for producing lenses worn today by people around the world,” Esposito explains. “Our solution is completed by VisionMaster™ software, which controls the material deposition—billions of droplets precisely positioned—to form lenses with or without prescription.”

The VisionPlatform™ is already in use in Europe and the United States. In fact, the company recently celebrated a milestone for its technology, with its customers surpassing the production of 50,000 lenses, destined for the traditional and smart eyewear markets as well as high tech industries.

Glasses, but smart

Despite the technology having existed for some years, smartglasses have so far failed to reallyreach consumer acceptance. Among the main reasons we don’t see people walking around donning Google glasses or other AR lenses is design: existing smartglasses tend to be bulky, which in turn make them unfashionable. Many have argued that they are, to put it bluntly, ugly. Another hurdle that smart eyewear developers have had to contend with is the fact that a significant percentage of the world’s population need prescription lenses. Luxexcel’s 3D printing technology can solve all of these issues for smartglasses manufacturers.

Esposito elaborates: “Tech companies need to bring to market smartglasses for consumers that look like everyday glasses. Our 3D printing allows them to embed a smart device directly into a 3D printed lens. Thanks to this capability, the eyewear is thinner, with an estimated 50% reduction in overall weight compared to legacy lenses. At the same time, the smart device is also protected by the lens material, creating a rugged, dust-resistant and waterproof solution.

“By contrast, most traditional lens-making methods would require gluing or other fixing techniques. They also need to be operating at high temperatures to fabricate smartglasses. Traditionally, you would start with a lens, which you would then need to modify to attach the smart device. At Luxexcel, we have eliminated this assembly step and simplified the whole manufacturing process.

Manufacturing on Demand

“Ultimately, during the printing process, our technology enables the seamless integration, or encapsulation, of smart devices into the prescription lenses. Devices such as waveguides, holographic foils, flexible displays, active filters, liquid crystal technology, etc,” he says.

A trillion-dollar opportunity

The still-developing smart eyewear market, which has evolved (and stuttered) over the past decade, is expected to grow into a $1+ trillion opportunity—with a CAGR of 42.9% from 2020 to 2030 (Research and Markets). Luxexcel not only aims to be a part of this growing market, it plans to play an integral role in the segment’s growth thanks to its scalable solution for printing smart prescription lenses.

“In our path to smart eyewear, we identified three major pillars: the ability to print commercially-viable prescription lenses, the ability to produce them at scale and, finally, the ability to embed smart devices into said lenses.”

According to the Luxexcel executive, the company has already achieved the first two pillars. Luxexcel attained quality acceptance for its printed lenses as well as general market acceptance for custom lenses. Since reaching this first goal (in the form of ISO, ANSI and FDA certifications), the company has been working with its customers as well as internally to achieve volume production. As we saw last December, the VisionPlatform’s production scale was demonstrated when Luxexcel reached production of over 50k commercial lenses.

The goal today is therefore to meet the third pillar: to seamlessly integrate smart devices into its 3D printed prescription lenses. The way Esposito sees it, the ability to offer prescription smartglasses is imperative to the technology’s success.

“It is estimated that 70% of the adult population needs vision correction to see their best and function in every work and life,” he says. “By 2030, it is estimated that 8/10 will need some kind of vision correction. In short, many of the people that want to use smartglasses will need prescription lenses. Smart and vision correction was therefore a must for Luxexcel to enable the manufacturing of smartglasses. As you can see there is a convergence of health and tech happening. At Luxexcel we are uniquely positioned to enable it. We can print custom prescription lenses while integrating smart devices.”

WaveOptics partnership

Luxexcel is already taking tangible steps in the smart eyewear market. Most recently, it revealed a collaboration with WaveOptics, a designer and manufacturer of waveguides and light engines. Together, the companies are developing a module that integrates all three components needed for augmented reality (AR) smartglasses: the 3D printed prescription lens, waveguide and projector.

The AR lenses will be fabricated using Luxexcel’s jetting technology and will directly embed the waveguide into their curved, transparent structure. The 3D printed lens will also function as a mounting for the projector and can reportedly ensure perfect alignment in an optical module. Finally, the prescriptions can be printed on the lens and can be tailored to the wearer’s needs. According to Esposito, the smartglasses module will be unveiled on March 18th 2021, at the SPIE AR, VR, MR Fireside Chat. Prototype samples will become available as soon as Q2 2021.

“We are working on projects together with large companies to develop the next generation of smart glasses. So stay tuned for more,” Esposito concludes.

This article was published in collaboration with Luxexcel.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Tess Boissonneault

Leave A Comment