Purchasing discontinued and limited-edition parts from the original manufacturer can be expensive. Most of the cases, it’s not a problem depending on how wealthy you are, but whether you have found the correct method.

FacFox can quickly produce replacement parts to lower your maintenance costs or create custom parts to better suit your needs. Regarding your needs, we offer a solution with reverse engineering, 3D printing, and other technologies.

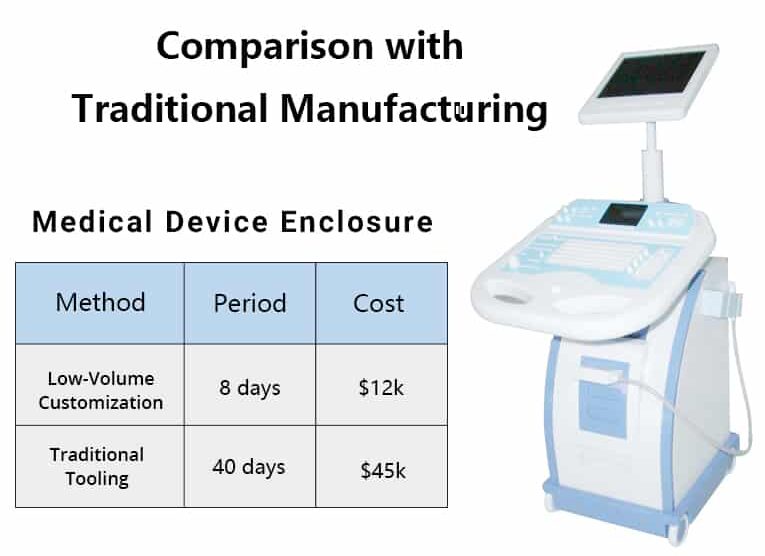

Seeing the 3D model with complex geometries like undercuts or cavities, traditional manufacturers will just turn you down. Not to say when you just quote for less than 100 pieces. Besides, the traditional tooling lead time can take several weeks and cost more than $10k. Not everyone can bear the costs.

Additive manufacturing gives developers maximum geometric design freedom, and complexity only plays a minor role in the production costs. No more expensive tooling process and no more minimum purchase volume. FacFox can customize parts in the exact quantity required. Be this means, we avoid unnecessary overproduction and guarantee maximum customer satisfaction. FacFox believes that our on-demand service can take the place of resource-intensive warehouses in the situation of low-volume production.

Our Advantages

Relying on advanced 3D printing equipment and technology, we have a team of professional engineers and designers, adhering to the spirit of craftsmen in the industry, and provide one-stop fast and small-batch manufacturing for new product development and production. “Many processes, many varieties, small batches, Fast delivery” to meet the customized small batch production order requirements of customers in various industries.

We specialized in the production of car tuning parts, medical equipment enclosures, electronic housings, drone housings, electronic connectors, and other product shells. All of the above products have reached the industry’s high level.

- Cutting-edge Technology: Rapid forming of parts with complex designs and intricate details.

- Short Production Period: The finished products can be produced in 2 days averagely, and the on-time delivery rate is 96%.

- High Product Quality: The quality of our products is recognized by more than 800 customers. We offer more than 10 kinds of finishing effects and can reach a precision of 0.2mm.

- Confidentiality System: We’ve set triple access controls on software, documents and plants, ensuring the safety from design, proofing, to low-volume production.

- Professional Team: Our specialists, owning more than 10-year experience in the manufacturing industry, can evaluate your plans practically and provide better solutions.

- Various equipment: We are equipped with various kinds of 600+ 3D printers and CNC machines.

- Buyer Protection: Full refund if you didn’t receive your order; remake if the item damaged during shipping; remake/refund if the item did not match your order.

Our Services

As a professional digital manufacturing solution provider who has been devoted for 10 years to turn your idea into real matters, we strive for clients’ best value by making parts with amazing quality, cost efficiency, and speed.

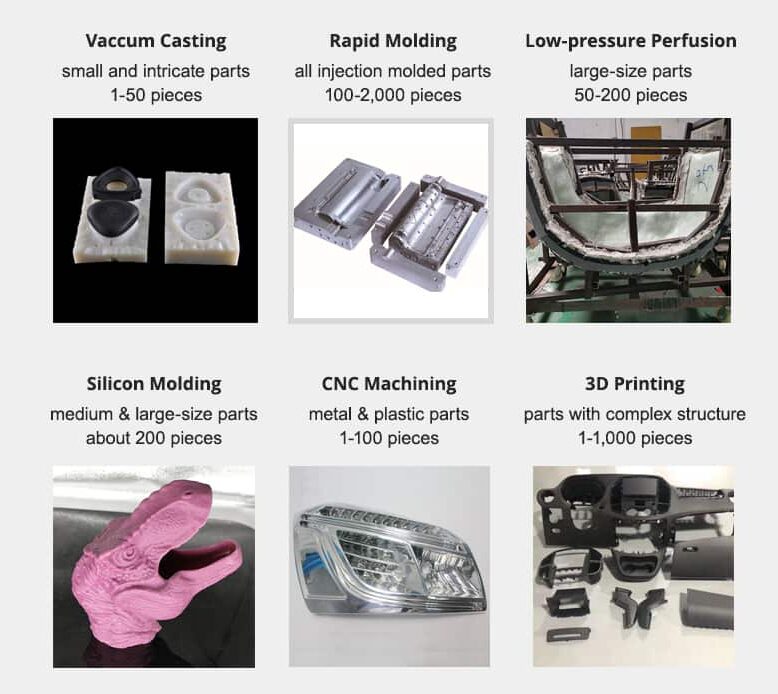

FacFox’s services include:

- 3D printing (FDM / SLA / MJF / DMLS / SLS / PJ / CJP…)

- CNC Machining (CNC Milling / CNC Turning)

- Injection Molding (Insert Molding / Overmolding)

- Sheet Metal Fabrication (CNC Laser Cutting / Plasma Cutting / Water Jet Cutting)

- Urethane Casting

- Metal Casting

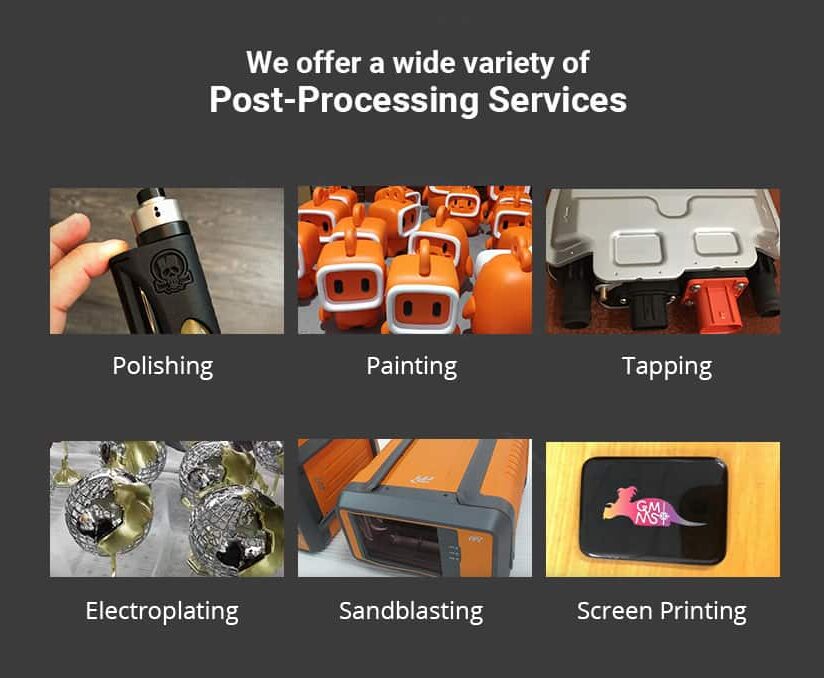

- Post-processing Services (Painting / Plating / UV-Coating / Anodizing…)

- Design, 3D Scanning, and 3D modeling.

- And more…

Our Plants and Manufacturing Facilities

Headquartered in Hangzhou, FacFox has factories and offices in Shenzhen, Dongguan, Suzhou, Changzhou, and Wuhan.

Case Sharing