When someone hears about 3D printing, they think of a cutting-edge production technology that has nothing to do with art and creativity, but this is not the case. To illustrate this aspect of technology, we recently interviewed the powerful architect and designer Serena Fanara. She designs and produces many product lines, including furniture accessories, jewelry, and gadgets, as well as lighting systems and event arrangements. At the core of all her work is the mission of environmental sustainability. To reflect this spirit, she launched the SeFa Design by Nature brand in 2015.

Based in Italy, Fanara is an early believer in the potential of 3D printing. This technology, combined with her expertise and talent, allows her to make her own designs more freely and faster than using more traditional methods.

3dpbm: What was the path that led you to combine your creativity with additive manufacturing?

Serena Fanara: It all started when I was in university in Florence, and I started creating furniture products for fun. I was already very active artistically: I was working with large installations for events and shows. From that point, I thought that I could combine my passion with studies, and I began to produce small furnishings, especially lamps. In this process, my training as an architect helped me a lot, as I was already well acquainted with 3D modeling software.

I have always been attracted to and inspired by plant forms in my designs. I believe they transmit harmony, and I like to reimagine them in my work. Over the years, I have also continued my research on neuroscience. For instance, I started to understand how my installations aroused different reactions in people based on the colors and shapes I used. In line with that, I started learning chromotherapy and ambient therapy—aspects that are too often relegated to the background, but which are very important for the daily well-being of all of us.

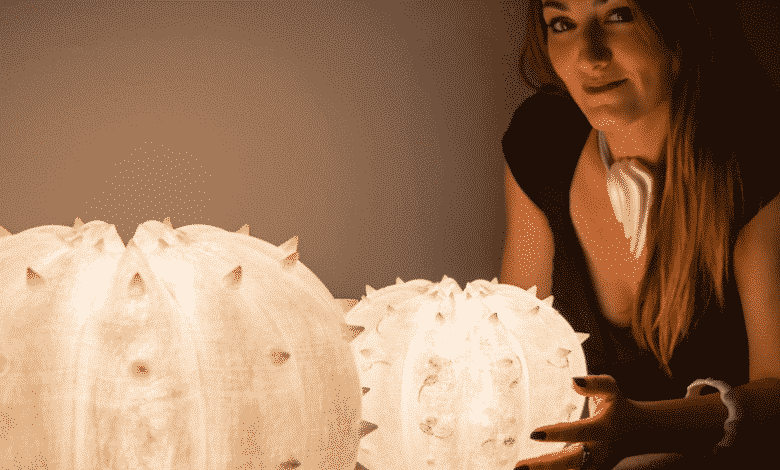

With my work, I can release my creativity through the particular shapes of my lamps and other creations. Using technology, I try to take my ideas to the maximum, creating objects that convey beautiful sensations. When I design on request, I try to personalize my client’s experience so that they can recognize themselves and feel completely at ease with the object or furniture they have commissioned.

3dpbm: Why did you choose 3D printing? What advantages has it brought you?

SF: I immediately understood the enormous potential of 3D printing: I have always created my works by hand and digital manufacturing has allowed me to produce very complex shapes, reducing processing times and margins of error.

Until about 2008, I worked with laser cutting. Then I met WASP in Milan during the presentation of one of its first 3D printers. From there I started to get closer to the world of 3D printing and to follow the company. When the first Delta4070 3D printer came out, I bought it. It was certainly a turning point from the production point of view, because the possibility of being able to experiment and correct mistakes quickly and without affecting the work was fundamental to raising the quality of the product and, consequently, the level of creativity. 3D printing allows you to speed up the time from idea to production, all with significant savings compared to traditional production techniques. For a designer, having the opportunity to work independently on their own ideas allows them to design with greater care and come up with a greater variety of concepts.

Another aspect that I noticed, is that the use of these technologies makes the role of the designer more flexible. You can easily change the size, shape, or color of a product using 3D printing. This allows for a greater degree of creativity and customization, making every single piece a little bit unique.