A payload containing 3D printed supplies for the 3D BioFabrication Facility (BFF) has arrived on board the International Space Station (ISS) docked 248 miles above the Earth’s surface. The cargo contained samples of human cells, bio-inks, and a set of new 3D printed ceramic fluid manifolds to replace the previously used printed polymers.

The new ceramic manifolds, produced through a partnership between Austrian ceramics specialist Lithoz and BFF launcher Techshot, are used inside bioreactors which supply the printed tissues with the nutrients they require to grow into usable patches. The new manifolds provide better biocompatibility with the tissue samples than the previously used printed polymers, resulting in greater yields of usable biological structures. The upgrade is regarded as a huge milestone by all parties involved.

Shawn Allan, Vice President of Lithoz, stated: “The success of ceramic additive manufacturing depends on working together with design, materials, and printing. Design for Ceramic Additive Manufacturing principles were used along with print parameter control to achieve Techshot’s complex fluid-handling design with the confidence needed to use the components on the ISS.”

What is the 3D BioFabrication Facility?

Launched in July of 2019, the 3D BFF initially made its journey out of the atmosphere in the cargo load of the SpaceX CRS-18 mission from Cape Canaveral Air Force Station. The bioprinter is the first of its kind, able to successfully print human tissue in the microgravity of space.

The printer is able to manufacture fine lines of human tissue emulating heart cells and other vital organs, thinner than a strand of human hair, from adult human stem cells and tissue-derived proteins which it uses as bioink. The end goal of the 3D BFF is to be able to manufacture whole human organs from scratch, although it is thought that this is still decades away.

Bioprinters on Earth have previously been successful in printing bones and cartilage but the manufacturing of soft tissues has proven more difficult. The relatively high gravitational forces present on Earth cause printed muscle tissues and blood vessels to collapse under their own weight, so researchers looked to the stars in hopes of success. Elsewhere bioprinting in space is underway with work by CELLINK and Made In Space.

Manufacturing on Demand

What it means for medicine

If the 3D BFF is ultimately successful, it could help eliminate the current shortage of donor organs present in hospitals around the world. Patients requiring tissue replacement would no longer have to wait for another’s death before they receive their vital transplants.

Due to the nature of additive manufacturing, the bioprinter would have the ability to manufacture patient-specific tissue replacements, using the patient’s own stem cells. This reduces the likelihood of tissue rejection and eliminates the need for a lifetime of immunosuppressant drugs.

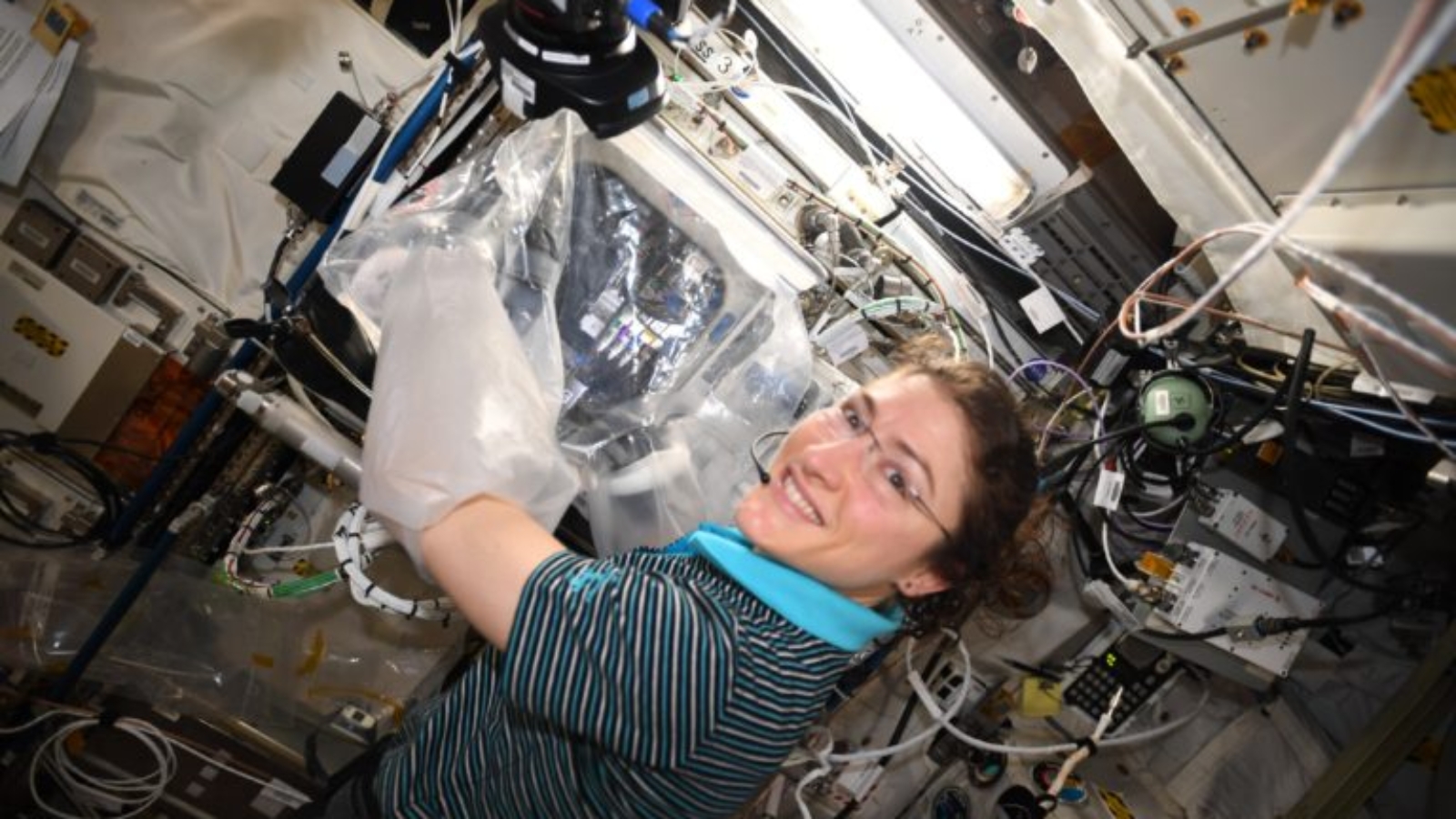

Featured image shows the 3D BioFabrication Facility. Photo via Techshot.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Kubi Sertoglu

Leave A Comment