Population aging is one of Europe’s great challenges in the 21st century. By 2024, 22% of Europeans are expected to be over 65. Patients suffering from chronic joint detop fects or defects in the oral and maxillofacial regions have a significantly reduced quality of life and are continually dependent on health care. The Covid-19 crisis has shown how dangerous chronically overcrowded hospitals and large cohorts of care-dependent and risk-grouped patients can become. Therefore, science and technology must work together to ensure that living longer can be synonymous with living well. INKplant, a project funded by the European Union H2020, was conceived to face this challenge and democratize its new solutions.

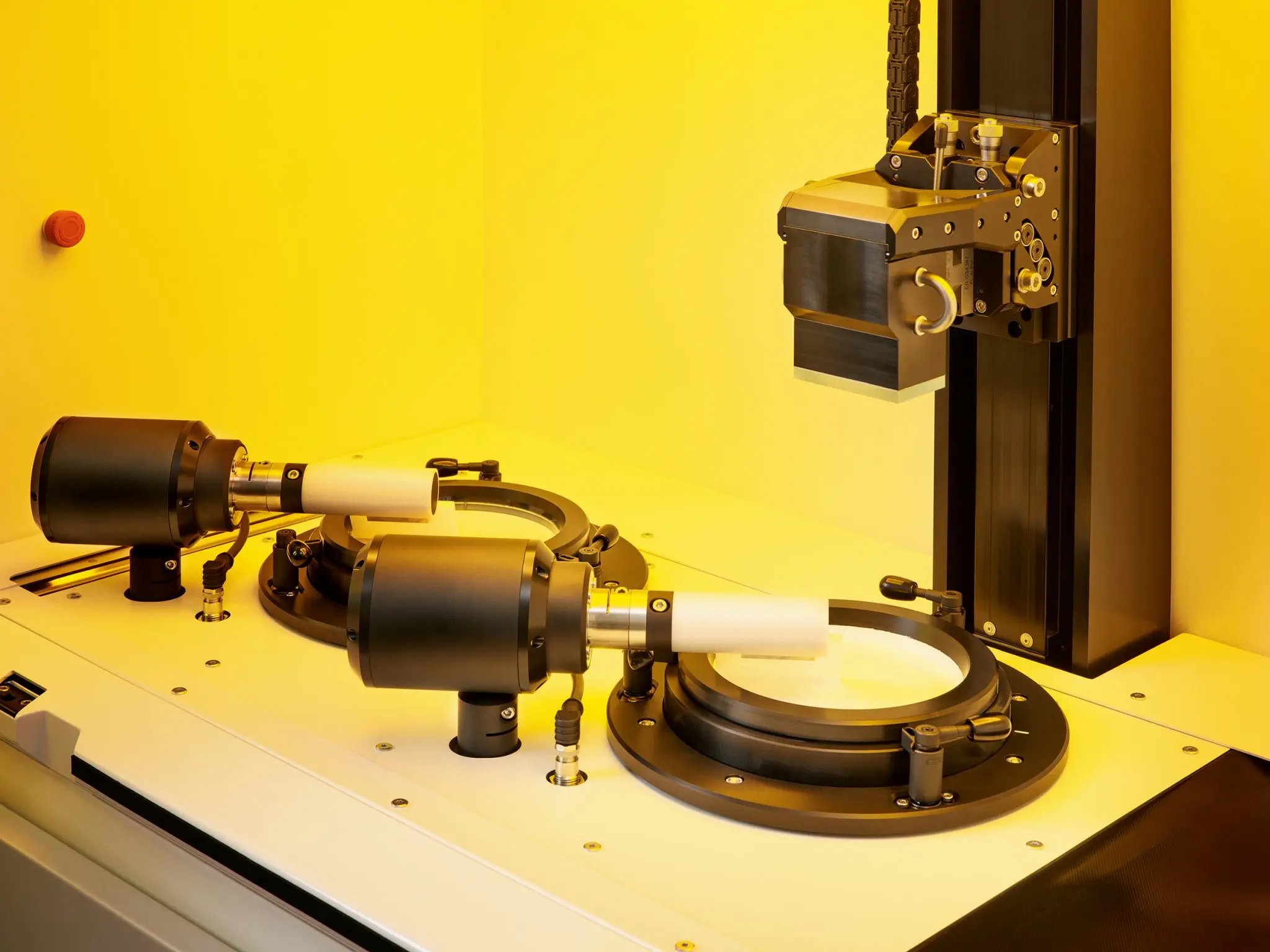

INKplant is an ambitious initiative with a €6 million budget that will create patient-specific implants by combining several advanced biomaterials and cutting-edge technologies. This is possible thanks to high-resolution additive manufacturing technologies (lithographic ceramic production and 3D multi-material inkjet printing) and advanced simulation and biological evaluation. The resulting implants will conform to each patient like a tailored suit.

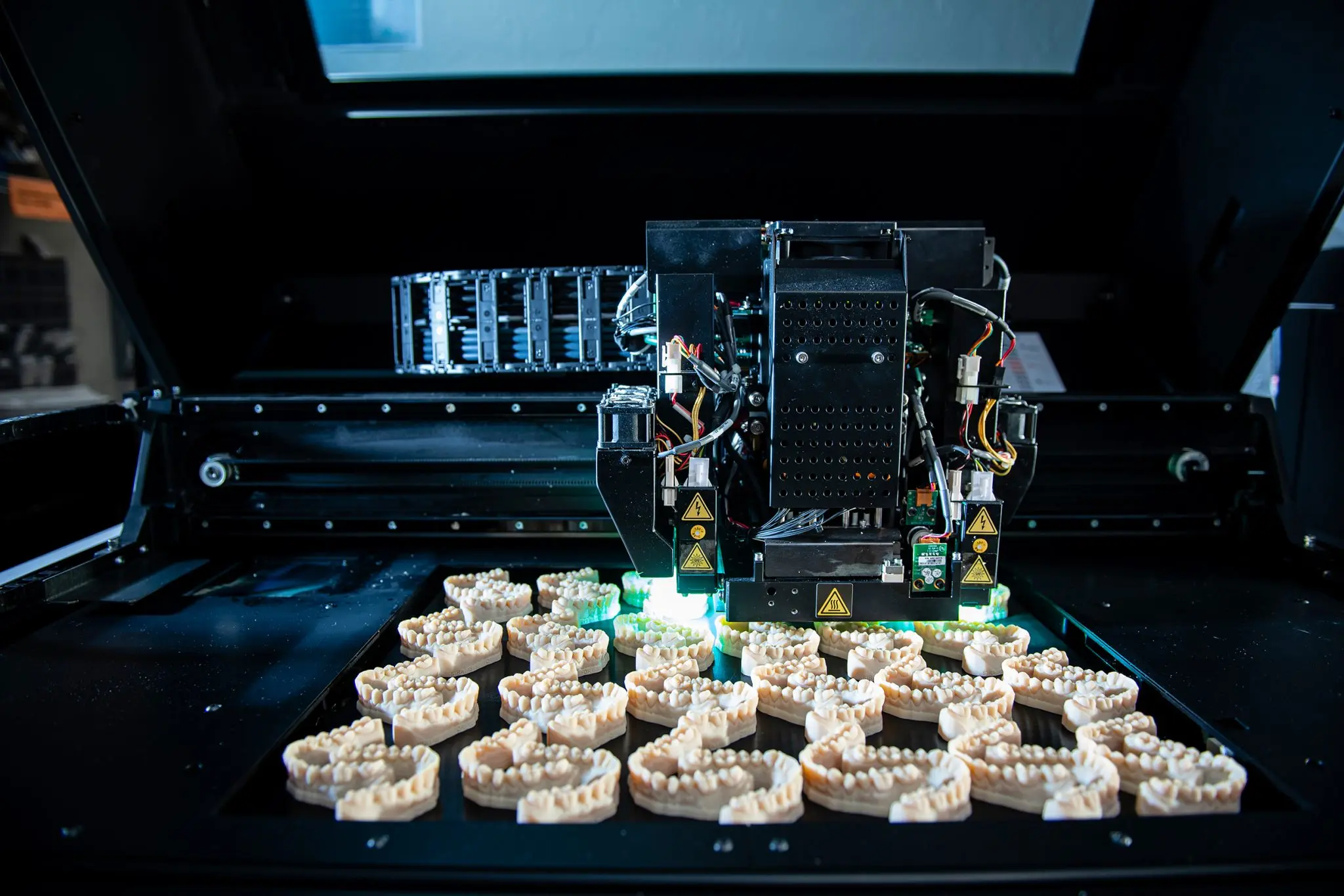

Ceramic stereolithographic 3D printing from Lithoz.

Reducing healthcare costs

The INKplant approach could significantly reduce or even avoid the need for invasive surgical procedures using inorganic prosthetic components. The methods envisaged in the project represent an enormous improvement in the quality of life of patients and will reduce the invasiveness as well as the complications deriving from the prosthetic components by improving the biocompatibility of the materials used.

INKplant will provide new solutions to some of the most widespread and urgent medical problems in European healthcare. Project partners will work on four different use cases: meniscus defects, osteochondral defects, palatal defects, and patient-specific implants for dental and oral rehabilitation

To alleviate the suffering of patients with joint defects, INKplant will develop meniscal implants and implants to repair osteochondral defects of the knee, thus avoiding the need for total joint replacement.

For defects in the oral and maxillofacial region, caused by common birth anomalies or as a result of diseases such as cancer, INKplant will develop implants for the repair of the palatal defect and implants for patients for whom, due to lack of bone in the jaws, neither conventional dental prostheses nor conventional dental implants have feasible treatment options.

Manufacturing on Demand

Personalized therapies

Medical tissue repair implants are currently manufactured in standard sizes and shapes from inorganic and non-resorbable materials. Unlike these current artificial implants and prostheses, which are perceived by the body as foreign materials, INKplant will enable the production of individually customized implants with improved biomechanical performance and biocompatibility that will not only alleviate suffering but also have the potential to promote tissue regeneration. damaged in the body.

By reaching the thresholds of complexity and detail in the production of materials with high precision and production capacity, INKplant addresses the complexity of the regeneration of different body tissues. In addition, the project will bring individualized and gender-specific treatments to challenge medical problems to mass production. With these contributions, INKplant aims to reduce healthcare costs and rehabilitation times.

This will be made possible by the hybrid additive printing process developed during the project. The implants will be characterized by their different materials that mimic the biological and mechanical performance of the affected soft and hard tissues.

Strengthening biofabrication in the EU

Coordinated by the Austrian applied research company PROFACTOR, 19 partners from seven countries are collaborating on this project to address some of the greatest threats to the quality of life during aging: reduced mobility due to joint problems and reduced oral function due to restorations unsuitable prosthetics. INKplant’s international team aims for excellence in innovation through cutting-edge technology and science and wants to tackle this ambitious challenge from a multidisciplinary and multisectoral perspective.

The consortium includes experts in tissue engineering, biomaterials, 3D printing, standardization, and bioethics. It also includes world market leaders in additive manufacturing such as Lithoz and Stratasys, and four different university hospitals, two of which are among the largest in Europe (Charité Berlin and Vienna General Hospital).

INKplant combines medical and technical expertise, together with cross-cutting issues such as standardization and ethical aspects. Only with this integrated vision of regenerative and personalized medicine is it possible to make a real impact in society.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Andrea Gambini

Leave A Comment