First discuss why metal printing needs support. Compared with SLS's use of powder self-supporting parts and SLA's massive support parts, SLM seems to be much more complicated. During the metal printing process, the high temperature of thousands of degrees and the large temperature difference can easily cause warpage and deformation of the parts. The presence of the support can better fix the parts and prevent thermal deformation; at the same time, due to the higher heat generated during the molding process, the powder The thermal conductivity is poor, and the support can play an important role in preventing overheating and rapid heat conduction. Third, the scraper is prone to mechanical disturbance during the powder spreading process. The support can firmly pull the parts to ensure the stability of the parts.

However, the metal support is not as strong as possible, because the removal of the metal support requires a lot of work, and the unreasonable design will cause the support to be unable to be removed. Therefore, the design of the support must not only follow the basic requirements of being strong enough, but also be relatively easy to remove. If the designed support can also remove the internal powder, it is perfect.

Although many 3D printing equipment manufacturers have launched their own support design software, materialise is no different than the leader in this field. Its newly introduced e-Stage metal support module has the advantages of greatly improving production efficiency, facilitating post-processing, and saving more materials. Important help.

Faster, easier and smarter

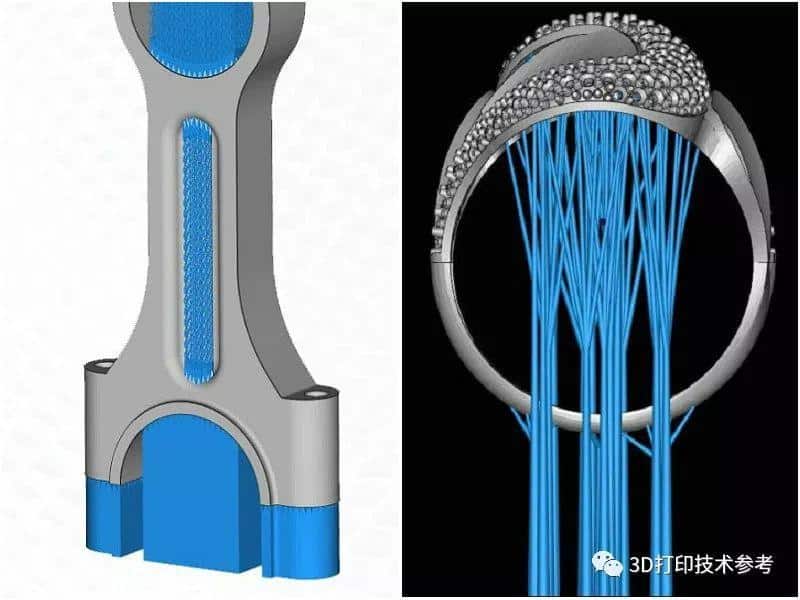

Prior to this, metal supports were mainly tree-shaped, tapered, and block-shaped supports, of which block-shaped supports were the most used, and tree-shaped supports were mostly used for jewelry printing. Although materialise claims that the SG + module can generate the most complete metal support, there are still great difficulties in removing the block support. Although it has a diamond-shaped hollow design, it is difficult to remove the powder inside, which can only be discarded during the online cutting process.

Block support and tree design

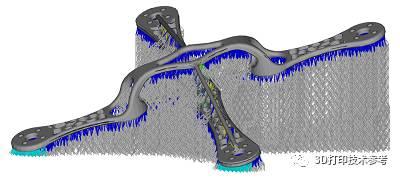

e-Stage aims to simplify the design of metal printing processes and generate support automatically. Operators can save data preparation and processing time, thereby reducing delivery time. Intelligent judgment needs to add support positions to avoid human errors, improve the success rate of processing, and reduce data preparation time by 90%.

Fully automatic generation of support structure

The super-large porous structure design makes the powder easy to release, so that more powder can be effectively used, and the loss is reduced by 20%.

Simple powder removal

The support mechanism that looks very tall

The reduction of connection points and the simple design of the disconnection point make post-processing easier and make the surface of the part more perfect, reducing post-processing time by 50%.

The support is easily removed, which is simply against the sky

Support is strong enough but weak enough

From the above introduction, e-stage does give us too many surprises, and the support no longer needs a hammer! I can't wait to use it, but I can't find resources. However, I believe it will not be used for a long time, it can still be used.

When many domestic manufacturers are learning materialise and supporting methods to launch their own software, it has gone further and deeper. The new version of e-stage also supports adding support to the SLA. As the parts become more and more complex and larger, the design requirements become more and more important. The support of automation can greatly improve production efficiency and simplify the support. Design will become increasingly important for post-processing.

Welcome attention

٩ (๑❛ᴗ❛๑) ۶

The original text originated from the WeChat public account (FacFox): how materially e-stage