Water scarcity is a major global problem. More than 1.1 billion people do not have access to the liquid that sustains life, while nearly 3 billion experience water scarcity at some point (WWF). In an effort to combat this reality—which has the potential to worsen dramatically due to the climate crisis—GE Research is teaming up with the University of California at Berkeley, University of Chicago and University of South Alabama to develop a 3D printed device that can turn air into safe drinking water.

The project, AIR2WATER, is being led by a GE Research team, which was selected for the four-year, $14.3 million project by the Defense Advanced Research Project Agency’s (DARPA). The innovative project is part of DARPA’s Atmospheric Water Extraction program.

At its core, the AIR2WATER project seeks to develop a portable device that can create clean water from air. The device will be compact and light enough that it can be carried by four people and will have the capacity to produce enough daily water for 150. The primary goal is to deploy the water-creating device to troops in the field so they have an adequate water supply.

“Today, the logistics and costs involved with transporting water are staggering and in dangerous war zone areas, result in casualties,” explained David Moore, Principal Investigator and Technology Manager for Material Physics and Chemistry at GE Research. “By creating a highly portable, compact device that efficiently extracts water from the atmosphere, we can save lives and ease the logistical and financial burden for our armed forces.”

Manufacturing on Demand

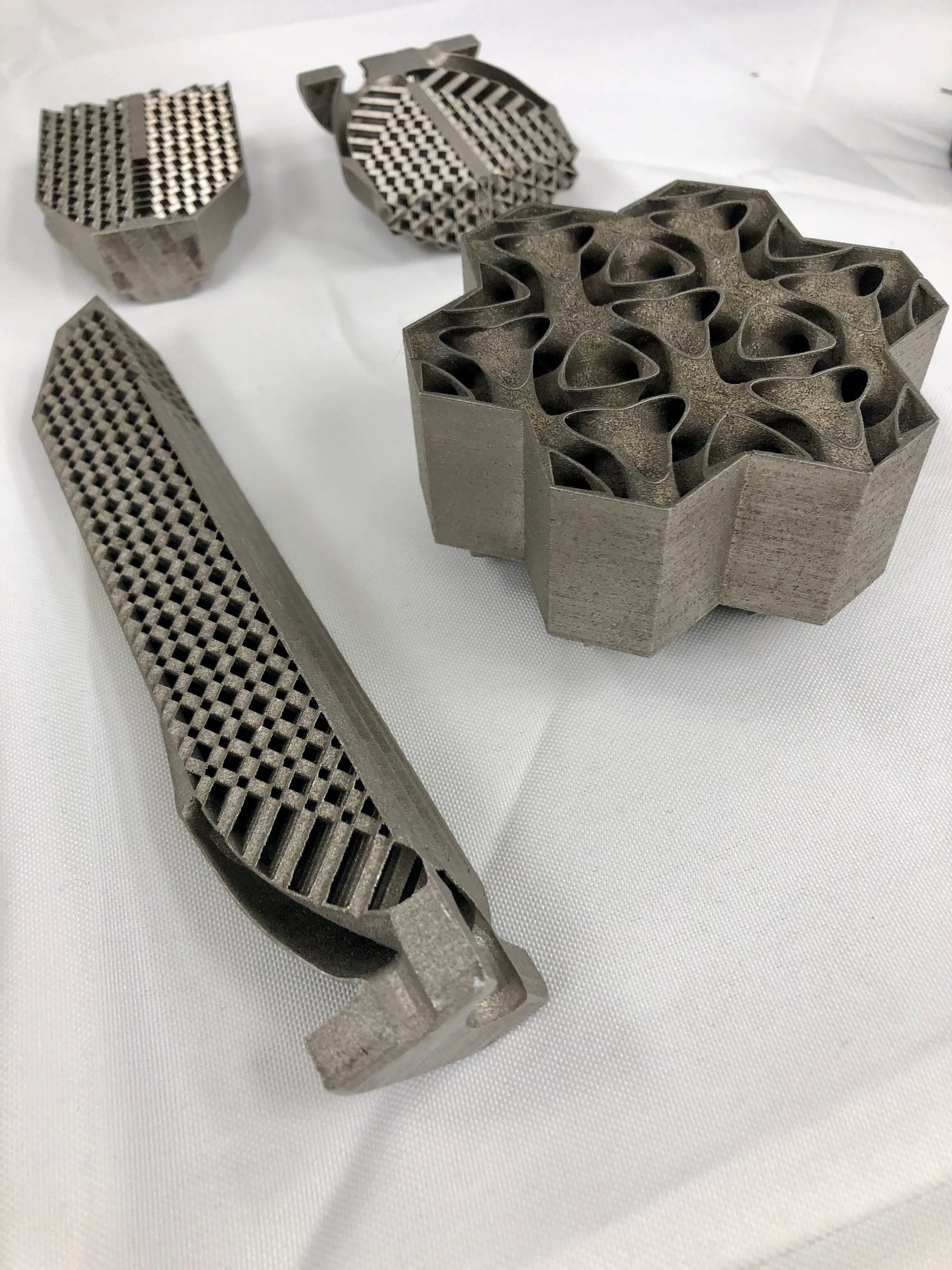

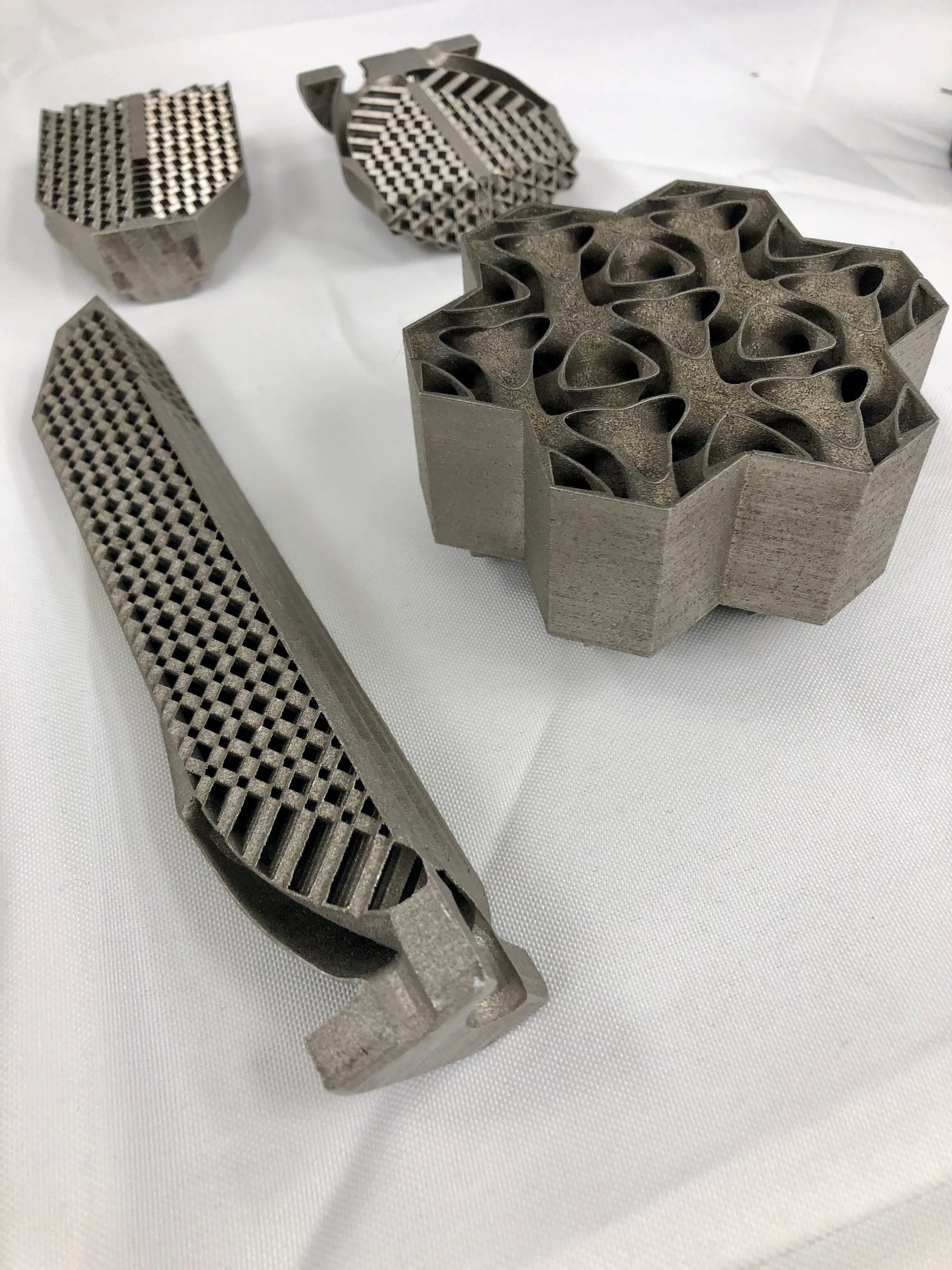

GE Research and its university partners are relying on a combination of innovative technologies and processes to develop the device, including new sorbent materials, thermal processes and additive manufacturing. As the company explains, the AIR2WATER device will use highly sorbent materials to absorb air, while a specially designed 3D printed heat exchanger will draw heat over the materials to release the water from the air.

Over the course of the four-year project, each partner will bring something different to the table. UC Berkeley and University of South Alabama have put top chemists and chemical engineers on the job to tackle the materials side, while AI experts from the University of Chicago will implement AI-guided molecular screening tools. GE researchers will spearhead the overall system, from the 3D design of the heat exchanger to the integration of the sorbent materials. The former will rely on GE’s extensive experience in the aerospace and power generation sectors.

The DARPA AWE program aims to support the “development of small distributed systems to reduce risks and costs associated with delivering potable water to troops in the field and for humanitarian missions.” By creating water out of air (and on site), there is the potential to drastically streamline military logistics in the field, saving time, money and resources. Down the line, the technology could also be used to help solve water scarcity around the world.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Tess Boissonneault

Leave A Comment