Advanced composite materials company Hexcel has introduced a new conductive polymer-based carbon fiber composite material for 3D printing.

The company’s new thermoplastic HexPEKK EM is tailored to meet the needs of electrostatic management, electromagnetic (EM) shielding, and radiation absorption in advanced aircraft applications. By directly integrating EM quality into 3D printed parts, Hexcel’s materials can enable users to reduce expensive post-processing steps and provide “flight-ready” components from the start.

“The introduction of this advanced additive manufacturing material will enable the fabrication of extremely complex aerostructures with unparalleled structural and electrical functionality,” said Lawrence Varholak, Vice President of Additive Manufacturing at Hexcel. “It significantly reduces weight and cost while providing unlimited design flexibility.”

Hexcel’s growing 3D printing material portfolio

Founded in 1948, Hexcel is a well-known material manufacturer that not only provides materials for the 3D printing industry, but also provides materials for the wider industrial manufacturing industry. In addition to its product portfolio, the company also has vested interests in multiple areas, including aviation, energy generation and transportation industries.

Hexcel’s current product lineup includes a range of carbon fibers, fabrics, adhesives and tool materials, but those in the 3D printing field are likely to recognize its proprietary HexPEKK thermoplastic series. The polymer series has been optimized for the manufacture of aerospace components, and even meets the smoke and toxicity requirements (UL VO, OHS) inside the aircraft, and can be used in the industry for final use.

Hexcel’s aerospace additive research began in 2016 when it opened a new research center in Duxford, UK, aiming to develop new composite materials for the aerospace and industrial markets. A year later, the company took another step and acquired Oxford Performance Materials (OPM), a well-known producer of high-performance thermoplastics and carbon fiber reinforced 3D printed parts.

After the acquisition, Scott DeFelice, CEO of OPM, stated that its focus is “still focused on the application of PEKK” and that the company is “developing some exciting new materials.” Hexcel subsequently reaffirmed its commitment to the development of new PEKK aerospace materials by obtaining 3D printing parts approval from the multinational airline Boeing.

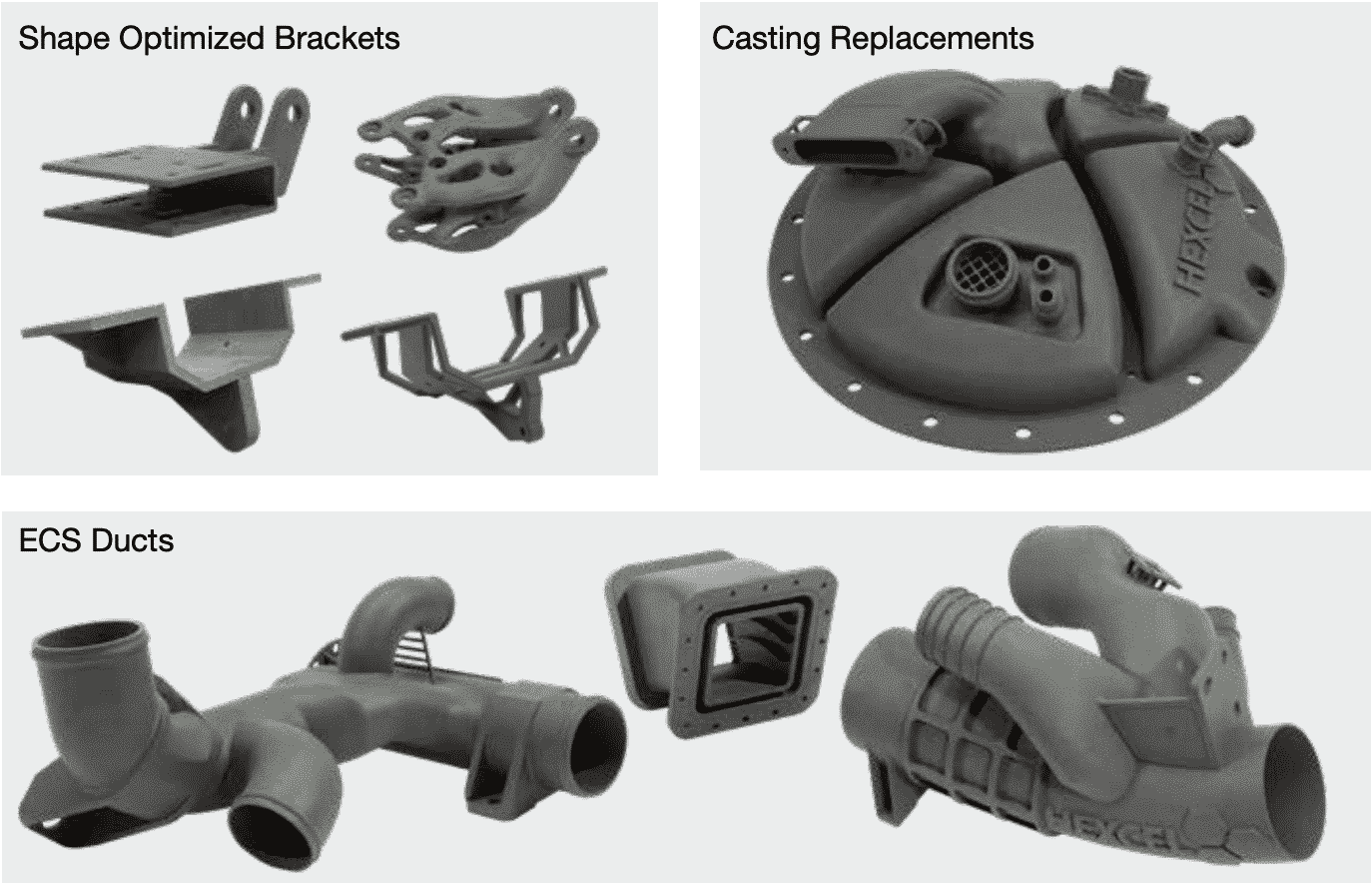

The certification is directly awarded to Hexcel’s HexPEKK polymers, which allows them to be used in the manufacture of brackets, environmental control system pipes and castings. With the release of the latest version of HexPEKK, the company now aims to solve more applications in the aviation field.

HexPEKK EM’s outstanding aerospace certificate

Currently, non-EM-enabled printing materials require conductive coatings to have the quality required for use in the aerospace industry. Electrical conductivity is critical in aviation applications because it allows parts to effectively manage electromagnetic interference and absorb radiation.

Hexcel’s new PEKK material has integrated EM characteristics, eliminating the need for such expensive and time-consuming post-processing tasks, which makes it likely to be suitable for printing various aerospace components. The polymer was developed using the company’s industry-certified HexAM process, which means that the polymer has demonstrated a high level of performance in terms of sustainability, working temperature and chemical resistance.

“In the design of all aircraft, the management of static dissipation, electromagnetic interference and radiation absorption is extremely important.”

The company’s self-described “industry-leading” materials are designed to produce end-use components for commercial aircraft, military aircraft, helicopters and drones. According to Hexcel, this makes HexPEKK EM an ideal choice for reducing the weight and cost of related components, such as air intakes, electronic enclosures and cockpit structures.

In addition, the inherent design flexibility of 3D printing may encourage the redesign of similar aerospace objects in a lower cost and more efficient manner. Moving forward, the company promised to continue to develop its patented HexAM process to “fundamentally improve the way the world’s aircraft components are manufactured.”

The role of PEKK in additive manufacturing

The heat resistance of polyetherketone (or PEKK’s) makes it popular in the aerospace industry, but researchers have also discovered more and more experimental methods to use its antibacterial properties.

3D printer manufacturer EOS developed its own carbon fiber reinforced PEKK material in cooperation with Boeing in April 2018. The polymer is designed to meet the challenging UV resistance, flame retardancy and federal aviation regulations in the aerospace industry.

Elsewhere, researchers at OPM and McGill University have demonstrated the antibacterial properties of the material by making 3D printed PEKK implants. OPM transplantation can repair bone cartilage, and reports have shown strong evidence of new bone formation.

At the same time, a team from Northeastern University developed 3D printed anti-infective orthopedic devices based on OPM’s use of PEKK materials. Inspired by the natural repelling surface of cicada wings, the team’s fine-tuning “nanohair” is said to be comparable to industry standard PEEK implants.