Global provider of advanced materials and additive manufacturing services, Henkel, has collaborated with dental product manufacturer Keystone to scale up 3D printing solutions for the dental industry.

The partnership will see Henkel add dental applications to its 3D printing portfolio, while Keystone will utilize the collaboration to increase its ongoing business in the sector.

“We are very pleased to find such a natural partner as Keystone,” said Ken Kisner, head of innovation for 3D printing at Henkel. “The combination of their longstanding know-how in the dental space with our broad material science expertise and market access will unlock new opportunities to develop and commercialize high-performance solutions for the dental markets.”

Additive manufacturing in the dental sector

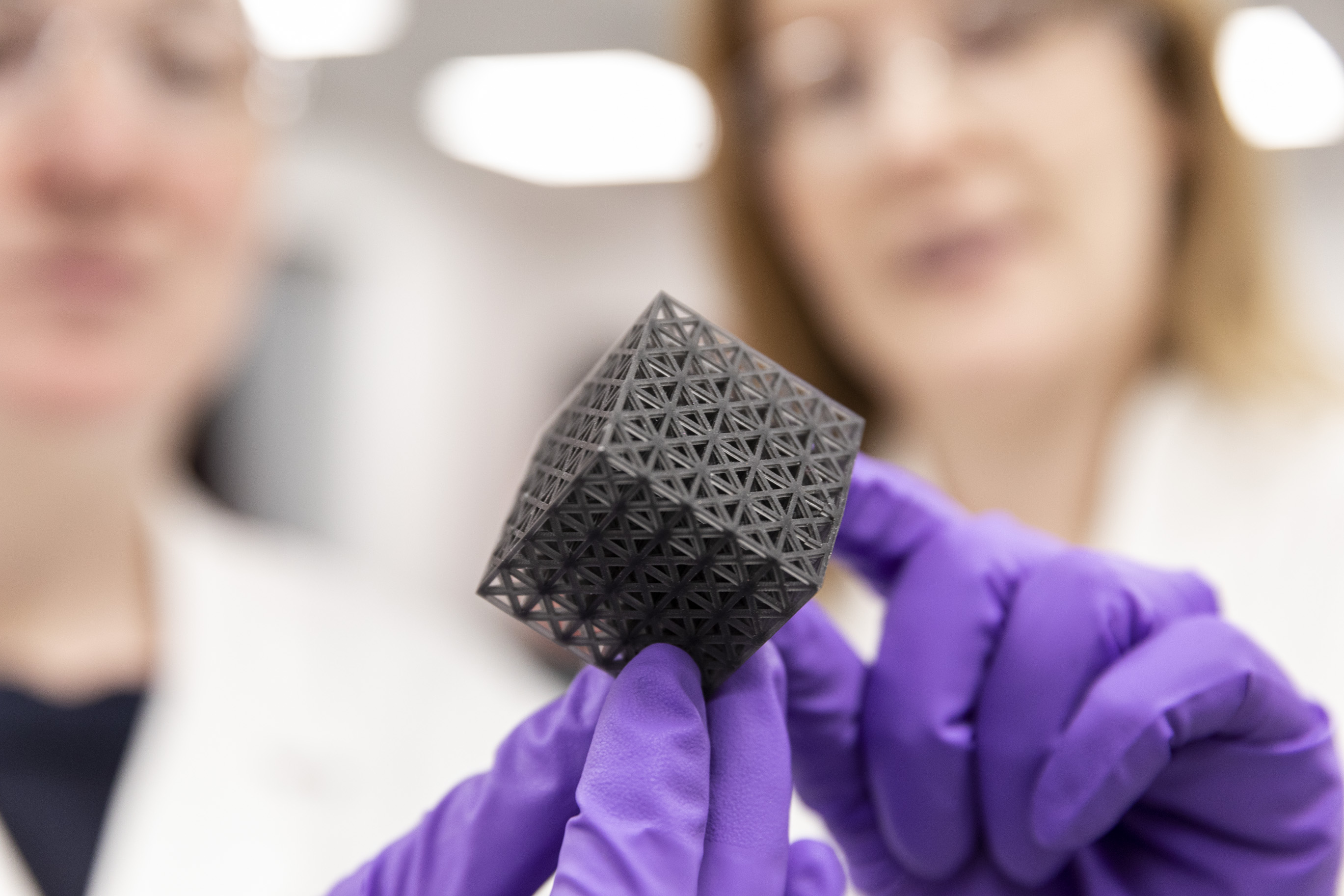

By its nature, 3D printing is suited towards the development of retainers, dentures, custom implants, crowns, and more; intricate, customized solutions that would otherwise be produced by labor-intensive, subtractive manufacturing methods such as milling machines.

Firms like SmileDirectClub, a Nashville-based teledentistry company, have recognized the potential of 3D printing in the dental sector. After announcing a partnership with US retail giant Walmart in January, its stock price (NASDAQ: SDC) shot up by 21% three days prior. Last year, at RAPID + TCT, SmileDirectClub announced a partnership with HP to increase the production of its clear aligners, with the deployment of 49 Multi Jet Fusion systems at the company’s Tennessee facility, which it claimed made it the “largest 3D printing facility in the United States.”

Since then, there has been a number of advancements in 3D printing materials and solutions for the dental industry, such as Swiss dental resin manufacturer Saremco Dental‘s new photopolymer resin for 3D printed crowns, inlays, onlays, and veneers. In June, post-printing developer PostProcess Technologies announced a collaboration with one of North America’s largest orthodontic laboratories to automate the company’s powder removal and surface finishing process for 3D printed dental products.

Most recently, SLA 3D printer manufacturer Formlabs added three new additions to its dental family of resins in July, aiming to cover all bases of a dental professional’s workflow.

Henkel and Keystone’s collaboration

Manufacturing on Demand

Well-known for developing and commercializing 3D printed solutions under its Loctite brand for the aerospace, automotive, engineering, and consumer goods markets, Henkel will now lean on Keystone’s polymer and ISO-compliant medical device manufacturing experience to add applications within the dental sector to its portfolio.

With more than a hundred years’ experience in the dental industry, Keystone offers a line of customized printing solutions under its KeyPrint brand. Keystone has long partnered with Molecule Corp, which was acquired by Henkel in 2019, however, the two firms enjoyed a longstanding business relationship prior to this.

As part of the extended collaboration, the companies will drive the penetration of Keystone’s KeyPrint line through increasing validations and partnerships with 3D printer firms alongside the innovation of new materials. It’s hoped the combination of the KeyPrint and Loctite brands will enable the efficient manufacturing of dental parts, while the two companies will also work together to develop opportunities, educate the marketplace, and market their 3D printing solutions on a global scale.

“We are excited to partner with a global industry leader and its professional team,” said Ira Rosenau, president at Keystone. “Henkel’s expertise and global presence will allow us to further bring our innovative 3D printing solutions to all corners of the dental market worldwide. The collaboration is a mutual fit for both companies presenting opportunities for further growth.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Hayley Everett

Leave A Comment