Fortify, a provider of advanced composite-photopolymer printers, has delivered a FLUX CORE 3D printer and Flux Developer materials onboarding software for the design and engineering of defense systems, to IERUS Technologies.

“Placing a printer at the IERUS Technologies headquarters provides a critical resource to support the growing need for additive manufacturing solutions in electromagnetics for defense,” said Eric Versluys, Director of Defense Programs at Fortify. “Fortify’s printers are uniquely positioned to print low-loss 3D printing materials, enabling performance advantages where traditional manufacturing falls short (due to machining, weight, and size).”

IERUS Technologies, a provider of engineering and design solutions, such as sensors and strategic systems, for defense and commercial customers, is designing novel RF structures such as Graded Refractive Index (GRIN) lenses leveraging Fortify’s FLUX CORE system. The Flux Core system enables companies like IERUS to take advantage of the design freedoms enabled by RadixTM, a 3D printable low-loss material developed by Rogers Corporation.

Manufacturing on Demand

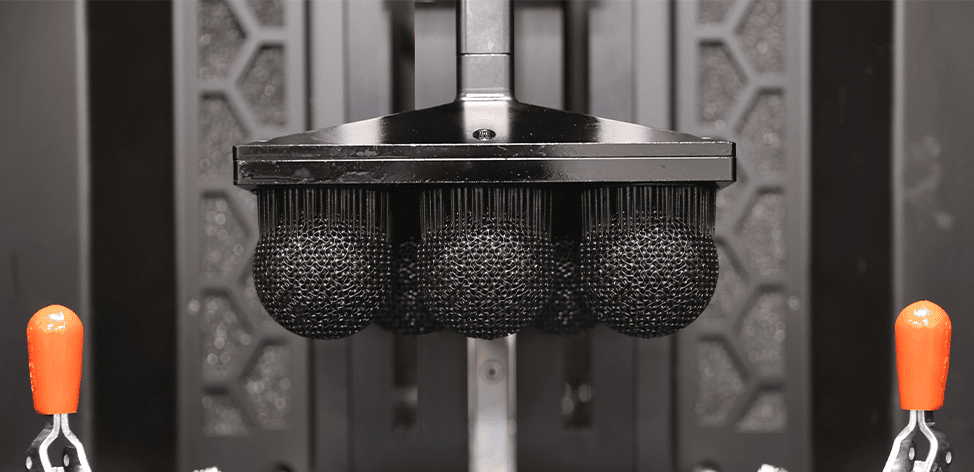

Fortify’s FLUX CORE 3D printer

Fortify’s FLUX CORE 3D printer

“The Fortify 3D printer line will enable IERUS Technologies to develop complex RF structures that push the limits of traditional RF architectures with novel electromagnetic phenomenologies,” said Jason Keen, CEO of IERUS Technologies.

This announcement comes a few months after Fortify’s strategic investment from In-Q-Tel and the development of a portfolio of electronic 3D printing materials. IERUS will leverage the Flux Developer toolkit, an open platform for the development of viscous and filled resins, to optimize the printing of RF devices.

Back in July, the US Department of Energy’s Advanced Manufacturing Office awarded $3 million to polySpectra and Fortify, along with National Renewable Energy Laboratory, MPI Systems, RePliForm Inc, and Oak Ridge National Laboratory to develop durable direct additive tooling for automotive lightweighting via Cyclic Olefin Resin-based composites. The goal of the project was to develop additively manufactured tooling with orders of magnitude improvements in cost and durability versus traditional CNC tooling with cycle times on par with CNC tooling.

You might also like:

nano3Dprint launches B3300 dual-dispensing 3D printer: The printer’s unique, proprietary dual material dispensing system can print two different materials together to build combined material prints. The B3300 expands users’ range of printing materials – from gold and silver to UV curable polymers and silicone.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment