A flurry of dental 3D printing developments have been announced ahead of the start of America’s largest dental laboratory event, Lab Day 2022, tomorrow in Chicago.

Resin-based 3D printer manufacturer Formlabs has announced a new partnership with dental 3D scanner provider Medit to make chairside 3D printing more accessible to dental practices, while 3D printer manufacturer 3D Systems has teamed up with dental material specialist Saremco Dental to combine its NextDent 5100 3D printer with the latter’s CROWNTEC material to open up a range of new applications for dental clinics.

LPBF 3D printer manufacturer Xact Metal, meanwhile, has announced its expansion into the dental sector in order to provide a “new level” of price and performance for the industry.

Formlabs to expand access to dental 3D printing

Through their newly-announced partnership, Formlabs and Medit are combining their respective capabilities to make chairside 3D printing more accessible to dental practices. Medit users can now download Formlabs’ PreForm app, a software integration for preparing dental CAD designs for printing on Formlabs’ machines, directly from Medit in order to simplify the in-office workflow for clinicians.

Dental professionals can scan a patient’s teeth using Medit’s i500 and i700 intraoral 3D scanners and then convert these scans into 3D printed models using PreForm and Formlabs’ Form 3B+ 3D printer. Clinicians will also be able to make use of Formlabs’ biocompatible resin portfolio, including its Permanent Crown and Temporary CB materials.

“Formlabs Dental is expanding access to 3D printing, and doing so requires partnering with industry leaders like Medit to address barriers to adoption in the dental industry,” said David Lakatos, Chief Product Officer at Formlabs.

“TOGETHER, WE’VE CREATED A COMPLETE CHAIRSIDE WORKFLOW THAT ADDRESSES THESE BENEFITS TO MAKE THE TECHNOLOGY MORE ACCESSIBLE, WITH THE ULTIMATE GOAL OF UNLOCKING THE BENEFITS OF DENTAL 3D PRINTING FOR BOTH PROVIDERS AND PATIENTS.”

3D Systems and Saremco combine hardware and materials expertise

Meanwhile, 3D Systems and Saremco have also combined their capabilities to advance R&D and time-to-market for the dental industry. The partnership will make Saremco’s CROWNTEC material available for use with 3D Systems’ NextDent 5100 dental 3D printer and dental software to produce patient-specific permanent crowns.

Described as a new-generation composite resin, CROWNTEC can be used to 3D print biocompatible permanent restorations such as crowns, inlays, onlays, veneers, and artificial teeth for dentures. The CE-marked material recently received 510(k) clearance from the FDA, and is offered in a range of shades to accurately match a patient’s teeth.

Combined with 3D Systems’ NextDent 3D printing hardware and software, CROWNTEC can be leveraged by dental labs and clinics to produce crowns and other restorations that are reportedly 30 percent stronger than those made from previous generations of crown and bridge materials.

“Our goal is to enable dental professionals to become more efficient and by doing so, ultimately improve patient outcomes,” said Stef Vanneste, Vice President and General Manager, dental, at 3D Systems. “3D Systems has established itself as the leader in digital dentistry solutions which includes our extensive portfolio of NextDent materials. As we innovate to meet our customers’ application needs, this strategic partnership plays a key role in helping to enhance our materials portfolio.”

CROWNTEC is now available with 3D Systems’ NextDent offering to customers within the US, EU, and other chosen markets dependent on regulatory approvals, in five shades: SW, B1, A1, A2, and A3. 3D Systems will showcase a variety of applications at its booth at Lab Day Chicago 2022, including its NextDent 5100, DMP Flex 200, ProJet MJP 2500 Plus, and ProX 800 machines and their associated materials.

“In Saremco, we found a partner that not only shares our values and beliefs in regard to innovation but also possesses expertise in digital dentistry,” Vanneste continued. “Their CROWNTEC material is a strong complement to our NextDent material portfolio, and is yet another step in helping dental professionals improve patient outcomes.”

Xact Metal expands into dental 3D printing

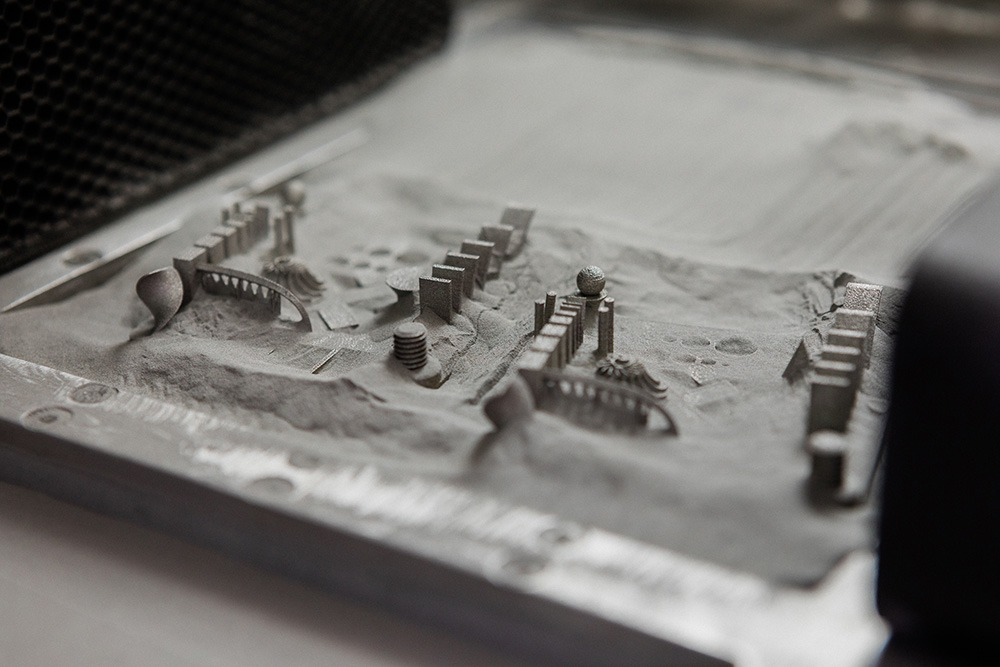

Ahead of Lab Day 2022, Xact Metal has announced its expansion into the dental 3D printing sector with a focus on metal dental applications. According to the firm, its newly introduced XM200G metal printer family is well-suited for the production of crowns, bridges, and removable partial dentures.

The company is offering its XM200G machines in tandem with Materialise’s Pre-Print Dental Module to provide a dental-specific workflow covering classification, error repair, print positioning, optimized support structures, and part nesting for the design and optimization of dental parts. The module is fully integrated into Materialise Magics Print for Xact Metal intuitive software to facilitate the 3D printing process.

Alongside its hardware and software offering, Xact Metal is also leveraging two certified dental powders from BEGO Medical. Mediloy S-Co is a cobalt-based dental alloy suitable for printing crowns and bridges, denture frameworks, implant prostheses, and other orthodontic applications. The second material, WIRONIUM RP, is specially engineered for the production of removable partial dentures with non-porous microstructures.

“At Xact Metal, we’re taking the essential specs of metal 3D printing and combining them with breakthrough technology to establish a new level of price and performance for the dental industry,” said Juan Mario Gomez, CEO of Xact Metal. “We have developed a high-performing and complete solution for dental labs using the newly-introduced XM200G with specific parameters tailored to the dental industry, a full software workflow in partnership with Materialise Pre-Print Dental Module integrated with Materialise Magics Print for Xact Metal, and certified dental powder from BEGO Medical.

“THE PACKAGE WILL MAKE IT SIMPLE FOR DENTAL LABS TO BEGIN PRINTING QUICKLY AND FOR A LOW COST.”

Leave A Comment