Fitchwork is a collaborative architecture, fashion, and product design practice founded by Travis Fitch. Driven by an obsession with pattern, Travis combines geometric research with novel design and fabrication tools to create radical-yet-rational forms.

Since its conception, in 2016, Travis has collaborated with an array of different companies to create projects ranging from 3D printed, runway-worthy dresses, to 3D printed reinterpretations of traditional household items, furniture, and light installations.

One of Fitchwork’s most notable projects, the Harmonigraph Dress, is an exploration of the relationship between body and cell, where the realization of a part is inseparable from the whole. The pattern and geometric structure of the 3D printed dress takes direct reference from the Fibonacci sequence – one of the most objectively beautiful naturally occuring patterns – and translates it into something that has never been seen before. Historically, it has never been possible to create something like this in the physical form. Fitchwork has made this dress a reality through adopting the design thinking associated with 3D printing and utilizing the available technology.

Manufacturing on Demand

One of Fitchwork’s other fashion-related projects is ‘Oscillation’ – another 3D printed dress, designed in collaboration with fashion brand threeAsfour and additive manufacturing company, Stratasys, exploring multi material printing in the production of couture.

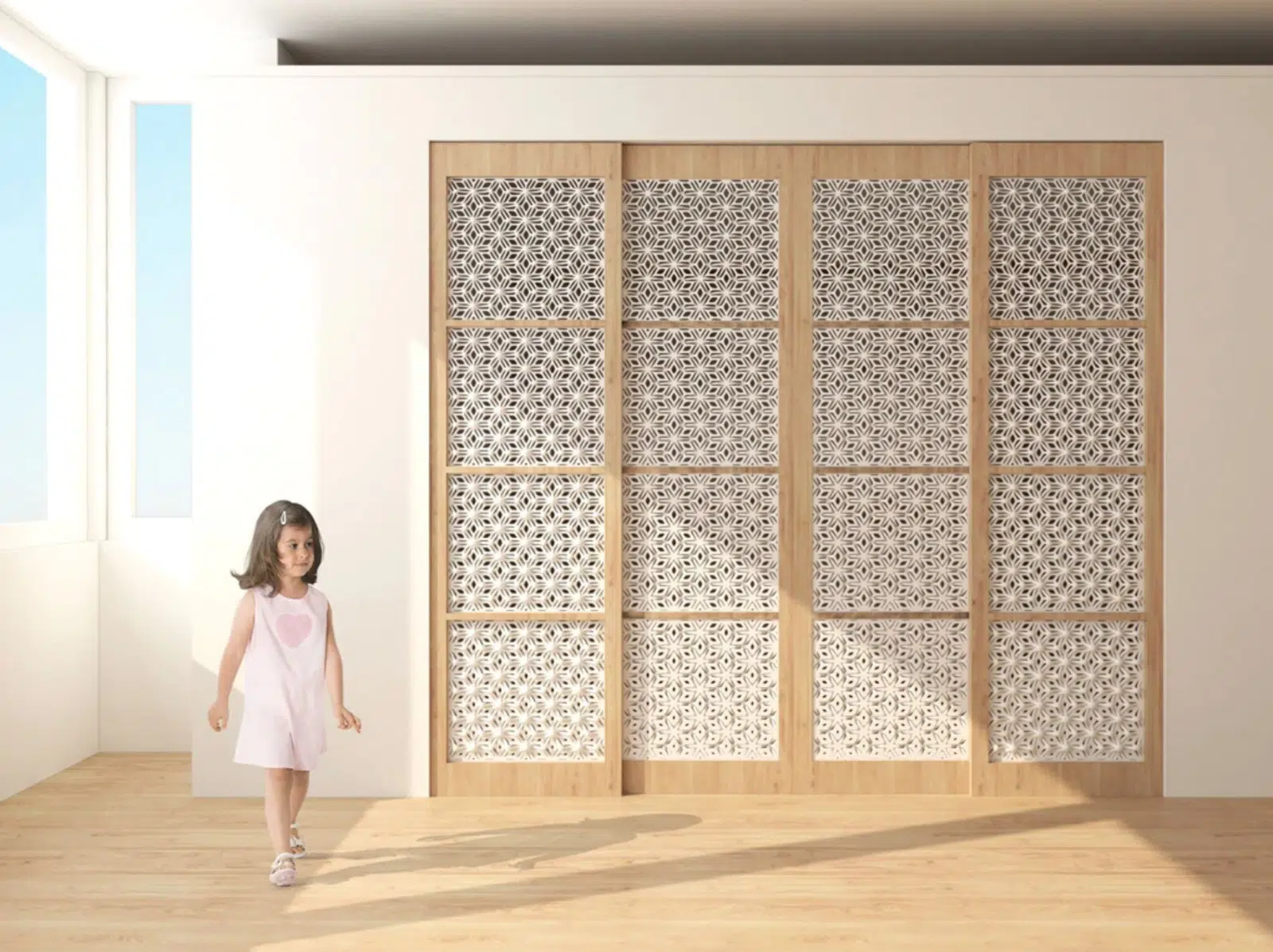

In addition to these dresses, Fitchwork has created the Texo Door, a reinterpretation of the traditional Japanese Shoji Screen, in collaboration with Japanese design studio, Yaitopale. The door was created for a kindergarten in Kobe, Japan, and was made by 3D printing PLA, in a pattern evocative of traditional Sashiko stitching, as a replacement for the traditionally-used material – paper.

Once again, Travis’ pattern-based thinking was reflected in Fitchwork’s Superpattern pop-up store in Manhattan, New York. The pop-up featured a collection of 3D weaves applied to a range of customizable, made-to-order objects. The objects were based on eight fundamental forms—a ring, a cuff, a bracelet, a necklace, a table lamp, a pendant light, a ceramic vessel, and an ottoman. The objects were made using a combination of tilling and weaving patterns through different methods, including laser-sintered nylon, silver or brass cast via a lost wax process, and porcelain slip-cast in a mold.

These processes bend the rules of materiality, freeing the interwoven patterns to flow around organic, curvilinear shapes in unprecedented ways.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment