A research team from the Swiss university ETH Zurich and the University Hospital of Zurich, led by Professors Robert Katzschmann and Omer Dzemali, has created a new 3D heart patch intended for implantation inside the heart. Published recently in Advanced Materials, the “RCPatch” is designed not only to close heart defects but also to support tissue regeneration.

“Traditional heart patches do not integrate into the heart tissue and remain permanently in the body. We wanted to solve this problem with our patch, which integrates into the existing heart tissue,” Lewis Jones, lead author of the study, explained.

Addressing Heart Damage and Advancing Repair Technology

Following a heart attack, disrupted blood flow deprives heart muscle of oxygen, causing tissue damage. In severe cases, this can lead to rupture of the heart wall, which requires immediate surgical repair. Currently, bovine pericardial patches are commonly used due to their structural stability and ease of implantation. However, these patches are biologically inert and remain foreign bodies, which can lead to complications such as calcification, thrombosis, or inflammation.

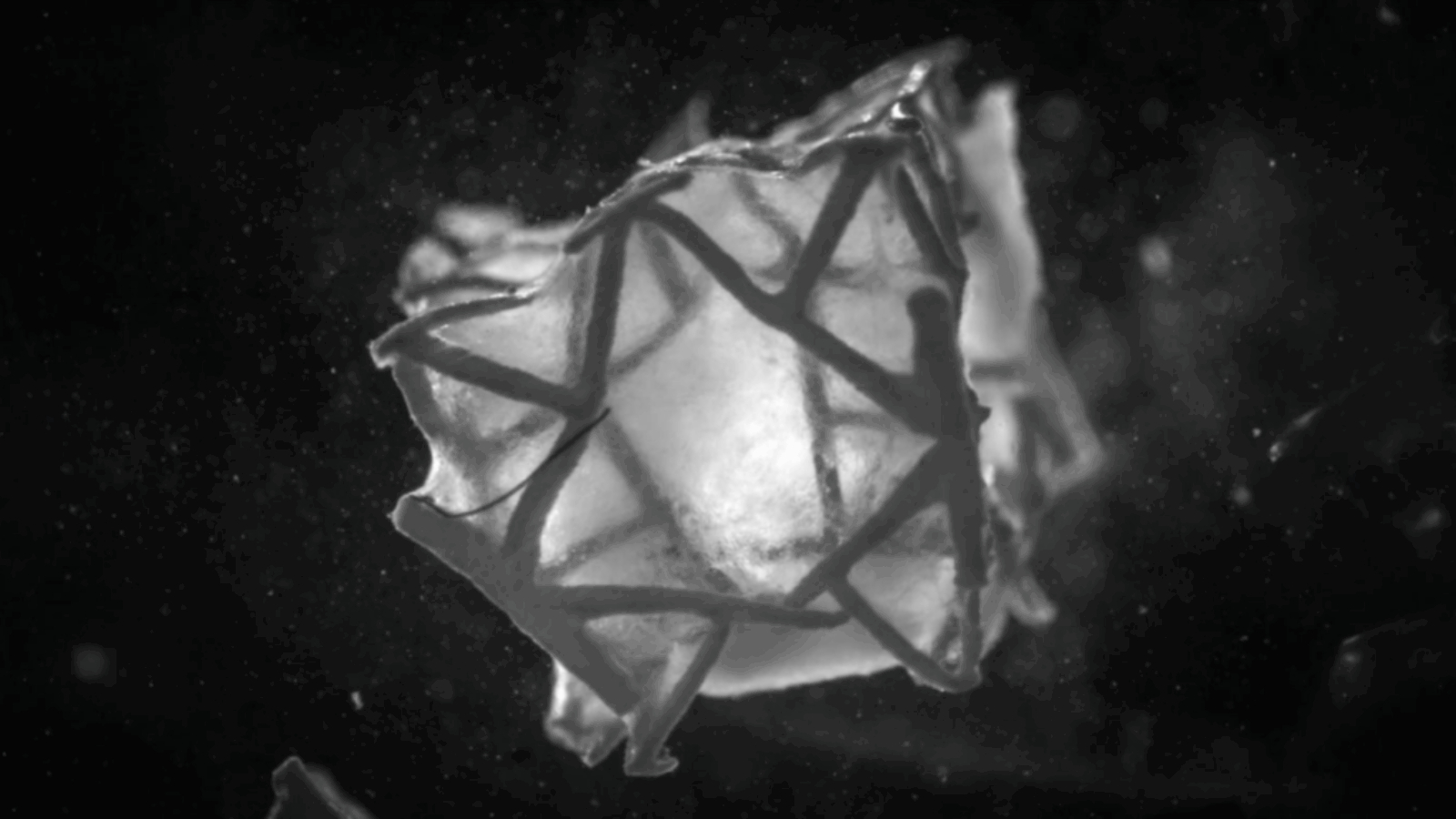

The RCPatch presents an alternative approach with three main components: a fine mesh to seal the damaged area, a 3D printed lattice scaffold made from a degradable polymer that provides mechanical support, and a hydrogel embedded with living heart muscle cells. The scaffold is designed to support tissue growth and fully degrades after integration, leaving no permanent foreign material. According to Jones, “The key advantage is that the scaffold degrades completely once the cells have integrated with the tissue, meaning no foreign body remains.” This combination creates a dense, user-friendly heart patch partly composed of living cells.

Preclinical studies using pig models showed that the patch could withstand physiological blood pressures, prevent bleeding, and aid in restoring cardiac function. The research team plans to continue refining the patch and assess its long-term stability in further animal studies. Their goal is to develop a tissue-engineered heart patch capable of both repairing and regenerating damaged heart muscle, potentially expanding treatment options after heart attacks.

3D Printing Advances in Heart Care

Manufacturing on Demand

A medical team at The Prince Charles Hospital in Brisbane recently performed a complex procedure to replace most of a patient’s aorta after scans revealed significant abnormal enlargement. Instead of relying solely on traditional imaging, the team partnered with the Herston Biofabrication Institute (HBI) to create a highly detailed 3D model of the affected artery. Using digital scans of the patient’s anatomy, engineers and designers produced a lifelike replica with the Stratasys J750 Digital Anatomy 3D printer.

This process took four days, during which the printer layered materials with varying textures to replicate both the structural and tactile qualities of human tissue. Having access to this physical model gave surgeons a much clearer understanding of the patient’s unique vascular anatomy, enabling more precise surgical planning than conventional 2D scans could provide.

Elsewhere, Triastek, a Chinese 3D printing pharmaceutical company, announced that its proprietary 3D printed non-vitamin K antagonist oral anticoagulant (NOAC), T20G, received Investigational New Drug (IND) clearance from the U.S. Food and Drug Administration (FDA). This innovation is expected to improve treatment for atrial fibrillation—the most common heart arrhythmia—affecting an estimated 30 to 100 million people worldwide (about 1%–2% of the global population).

You might also like:

Linköping University Researchers Develop “Skin in a Syringe” for 3D Printed Burn Grafts: The research received support from the Perling-Persson Foundation, the European Research Council (ERC), the Swedish Research Council, and the Knut and Alice Wallenberg Foundation.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paloma Duran

Leave A Comment