The city has lost its exquisite decorations, historical buildings are gradually in disrepair, repair costs have risen, and the number of people capable of doing this work has fallen. Edg, headquartered in New York, is a company that hopes to reverse this trend by using additive manufacturing. Founded in 2004 by the person in charge John Meyer, a team of 30 designers, engineers, and architects developed modeling software and localized 3D printing systems to restore the historical appearance to the scene.

Edg’s system uses custom molds to cast its design-Meyer admits this is not a new concept. He added that innovation is the company’s design process and the localized printing system that has been improved over the years. Instead of packaging and transporting the cast product from the printing plant to the project site, Edg can perform 3D printing molds and on-site casting decorations before installing the finished product in the designated location, which will increase delivery time and the possibility of damage.

Meyer believes that one of the greatest advantages of Edg technology is efficiency. He said that in communities where tight budgets often lead to “boring, monotonous designs,” this technology allows them to “add decorations to buildings in a cheaper and more economical way.”

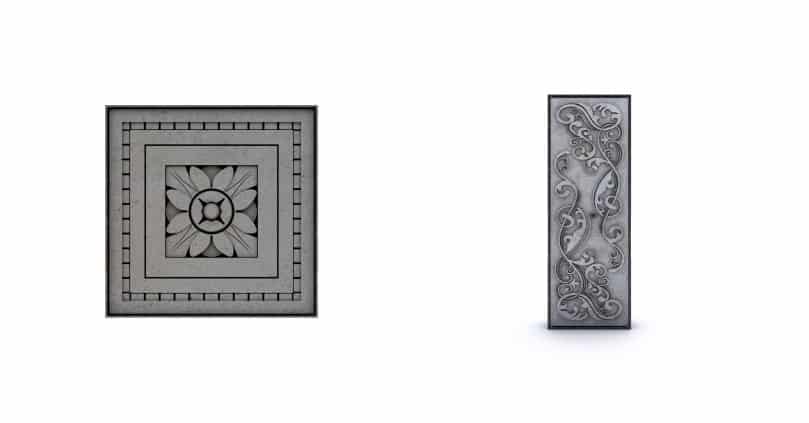

When Edg was committed to developing manufacturing partnerships, it launched Synthesis 3D, an extension of the design company’s creation of 3D printed objects to help fund the company’s long-term research on 3D printed facades and large-scale projects. These products usually appear in Edg’s interior design projects in the form of feature walls and furniture pieces, such as concrete tables in the form of large bolts.

With the office’s recent acquisition of a 3D printer capable of printing 3½-foot cubes, Edg was able to prototype its decorations more quickly. The team not only experimented with designs and proportions, but also experimented with different printed materials, such as flexible or water-soluble concrete mixtures.

“We’ve been able to reduce the cost of a lot of our printing parts—to between 30% and 50% of what it originally was just by experimentation, understanding the limits of the technology [and] the materials,” Meyer says. “We really refined our process, and we’ve turned it into a nice kind of manufacturing line.”

Meyer and Edg’s team, including Edg’s vice-principal and design director Richard Unterthiner, are integrating other development technologies into Edg’s workflow, such as high-resolution laser scanners to scan and render facade fragments. These scans can inspire further designs, but can also simplify the repair of damaged building components. For example, Edg does not need to re-engrave the historical appearance, but can scan the elements and re-3D printing.

Meyer and Unterthiner also see potential in reducing the cost of bespoke design through a friendly user interface, which will enable end-users to have a hand in transforming their own environments. “Everyone wants something unique in the marketplace now,” Unterthiner says. “Everything is out there to be looked at, studied, and inspired by; so we take that and work with our clients and come up with something new and modern that can build on the whole lexicon that cities have put forth.”