Desktop Metal launched copper for the Studio System, an office-friendly metal 3D printing system for low volume production. With its excellent thermal and electrical conductivity, copper is considered an ideal material for transferring heat or electricity and is used in virtually every electronic device made.

Copper is the latest addition to the Studio System materials library that also includes 4140 chromoly steel, H13 tool steel, 316L and 17-4 PH stainless steels. In addition to materials that are already available, Desktop Metal’s team of materials scientists are continuously working to develop new materials and processes to make 3D printing accessible to even broader industries and applications.

The copper material used with the Studio System is pure copper. Unlike laser-based processes, which often print chromium zirconium copper, the Studio System’s proprietary Bound Metal Deposition process is able to print pure copper, unlocking the full benefits of the material.

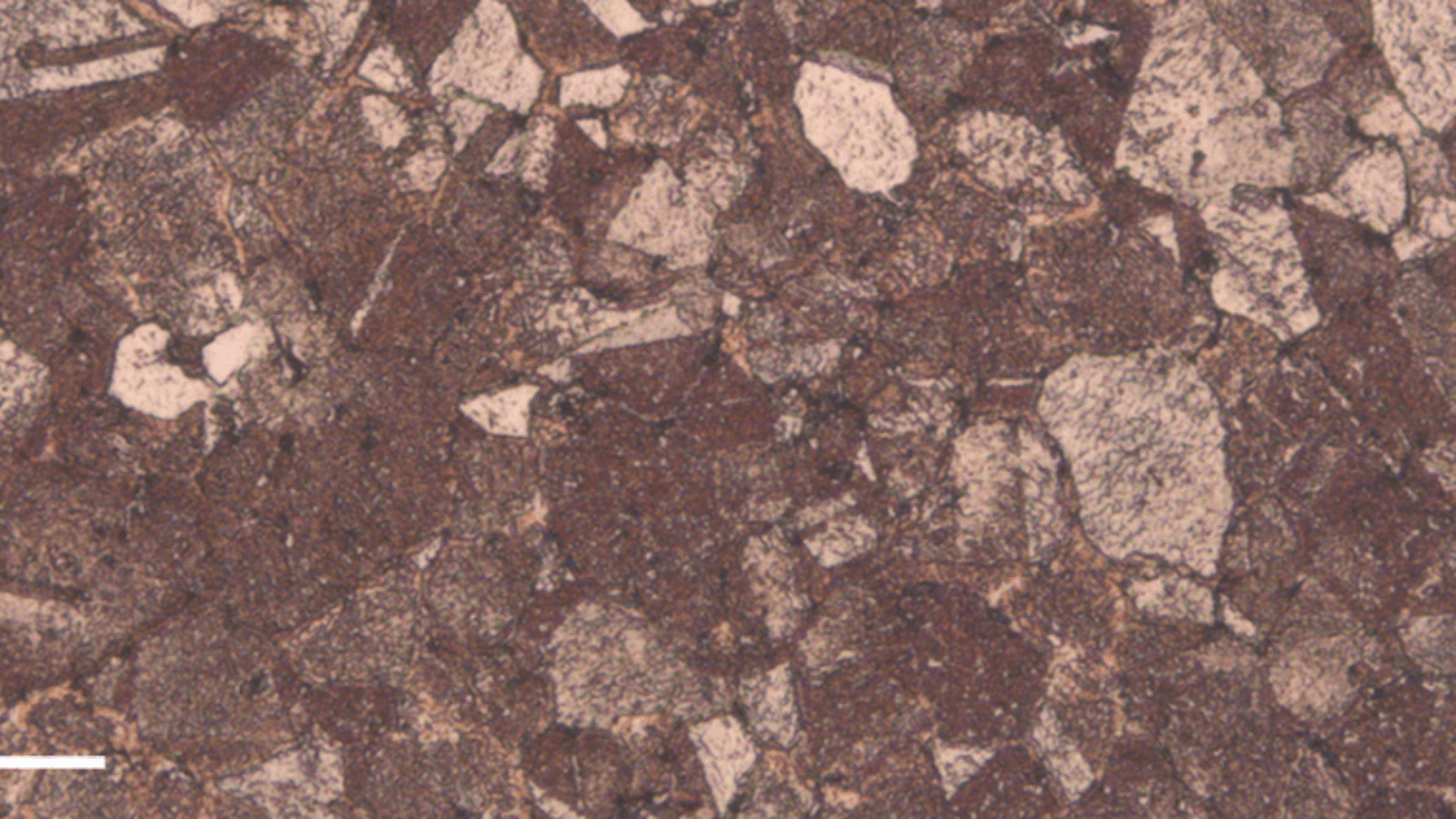

The metallurgy behind the Studio System is built upon the materials science and established powder supply chain of the metal injection molding (MIM) industry. When combined with Desktop Metal’s in-house expertise in material processing, binder compounds, and metal 3D printing, the results are high-quality metal parts with affordable material costs.

Manufacturing on Demand

Early customer applications demonstrating the material’s benefits include:

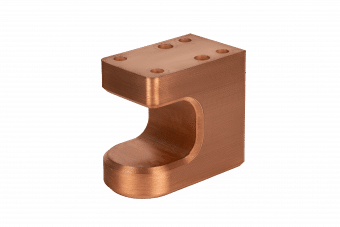

Manufacturing: Electrode Holder

Electrode holders are used to hold electrodes in position during resistive nut welding. Printed in copper, the

Automotive: Motor Heat Sink

Chemical Processing: Helical Heat Exchanger

Helical heat exchangers are used to cool a hot gas as it flows through a pipe. The Studio System allows for theheat exchanger to be printed with an internal helical channel that enables cooling fluid to flow through it. The complex geometry of that channel can only be made with additive manufacturing.

Electric Power Distribution: Bus Bar

You might also like:

RIZE touts a fifth product to achieve Greenguard certification: The RIZE 2XC is RIZE’s fifth product or material to obtain Greenguard certification, and the first product of the RIZIUM Alliance to obtain such certification. The RIZIUM Alliance allows traditional fused deposition modelling 3D printer players to implement safer, sustainable, recyclable 3D printing on a variety of platforms, while still delivering highly durable, market leading solutions. The RIZE 2XC certification makes RIZE the number-one provider of Greenguard certified products in the 3D printing industry.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Adam Strömbergsson

Leave A Comment