Researchers are exploring 3D printed mandibular models will help provide by exploring the technology that is the very best possible, enhanced remedy. Detailing their findings in ‘Evaluation of the Dimensional Accuracy of 3D-Printed Anatomical Mandibular Models Using FFF, SLA, SLS, MJ, and BJ Printing Technology,’ we understand a wide range of techniques can benefit both patients and professionals.

Since 3D printing continues to infiltrate a vast assortment and programs also –many procedures and materials are readily available to make 3D printed models that help in the identification of health conditions. Designs and implants have been 3D printed more frequently today with great success, assisting individuals to recover and enjoy a much greater quality of life following surgery to remove tumors in the jaw region nonetheless, challenges still exist in producing entirely functional anatomical models with no an assortment of inaccuracies and deformations.

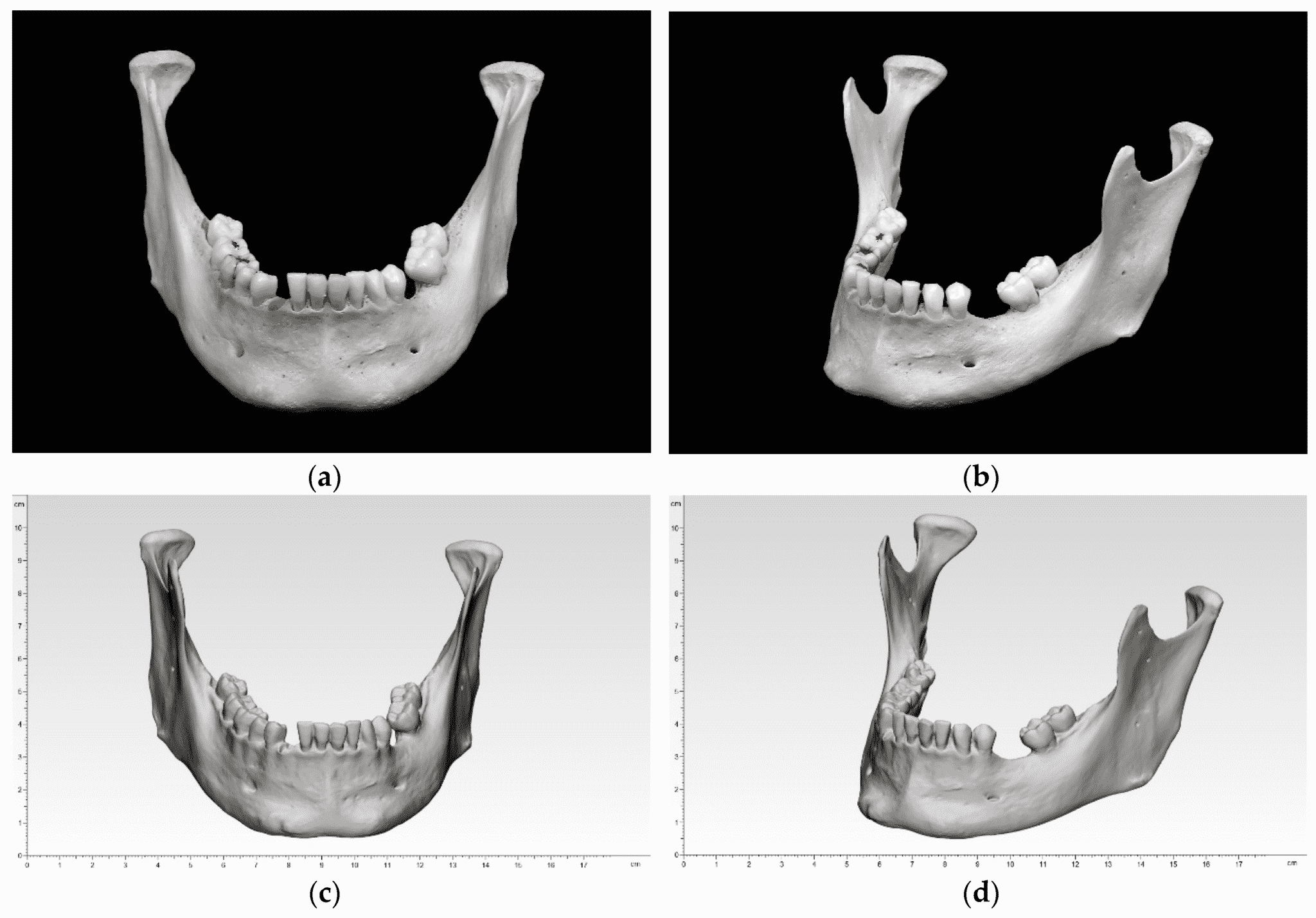

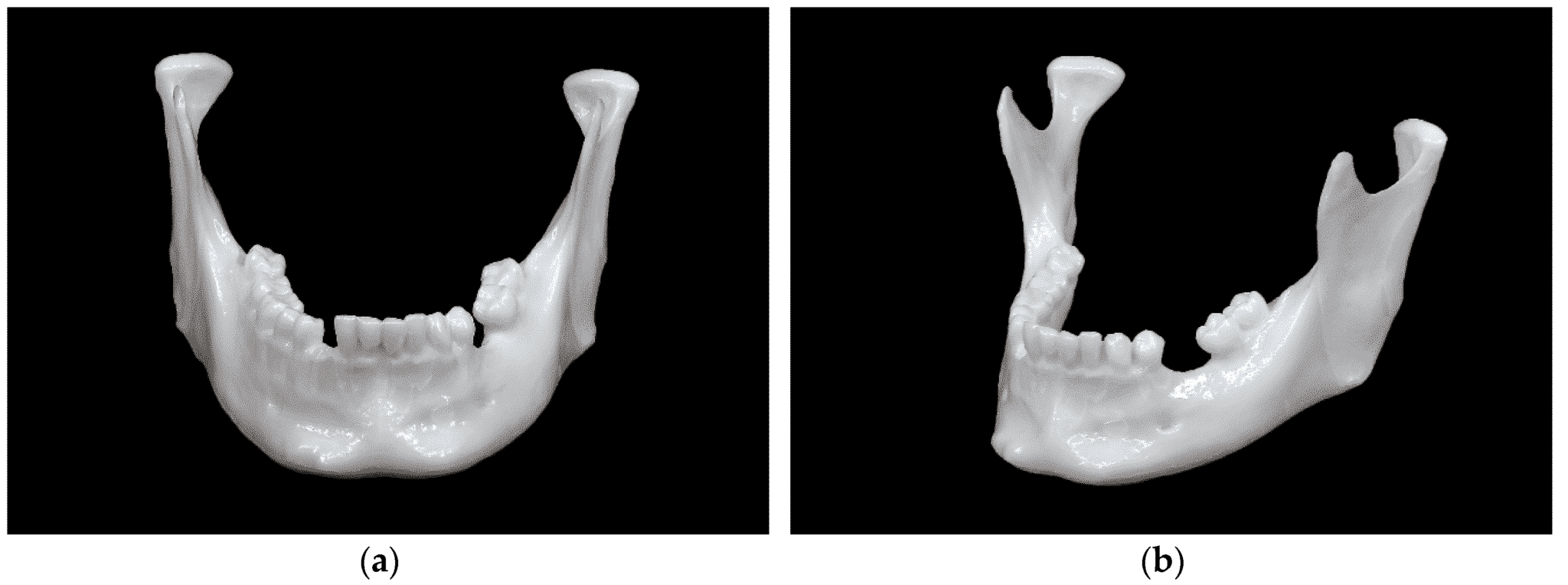

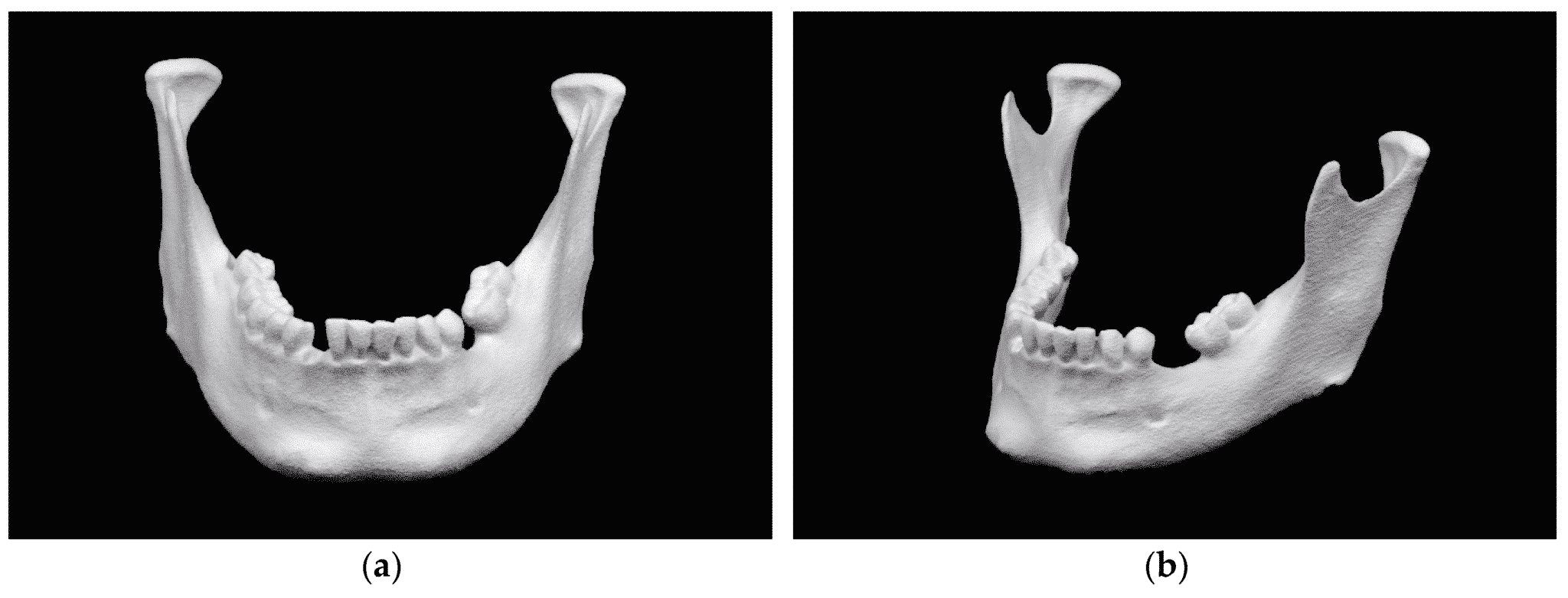

The investigators jumped to making the .stl document on a scanner that was high-precision, noting their procedure led to’significant decrease in malfunction sources’ Their aim was to compare 3D printed mandibular versions generated through practices that are different. Ten samples of a sterile bony mandible were fabricated on five kinds of 3D printing technologies.

“To leave the occlusal plane untouched for later analysis and to minimize the number of support structures required, all models were aligned vertically,” explained the researchers.

“Minor adjustments were made in the 3D slicer software before 3D printing. These adjustments ensured that the printing conditions corresponded to a clinical routine with a reasonable printing time and printing costs for a single model. According to the applied 3D printing technology, an adequate post-processing was conducted.”

Results seeing every System of technologies had been as follows:

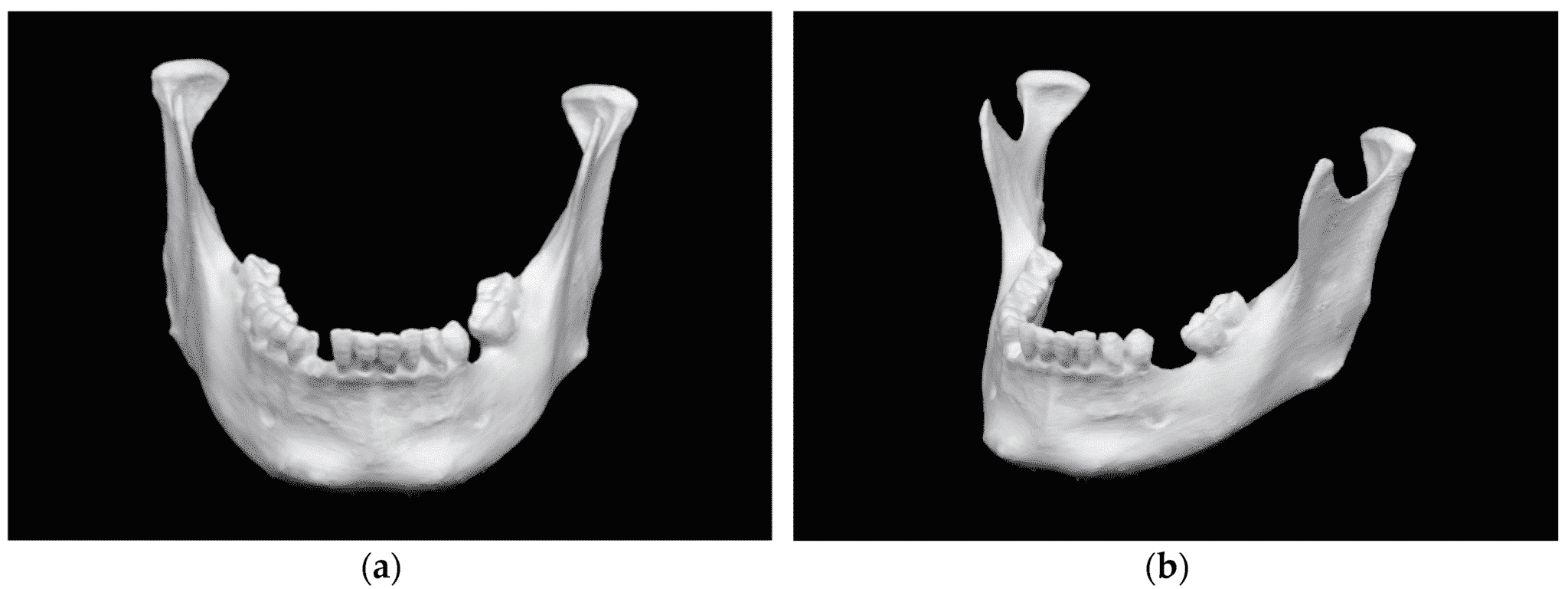

- FFF 3D printing — Little parts of support arrangements were mentioned, and ramus area markers were’fuzzy.’

- SLA technologies — surfaces were smooth, but the area was’not shaped.’ Ramus region markings were mentioned as well-defined.

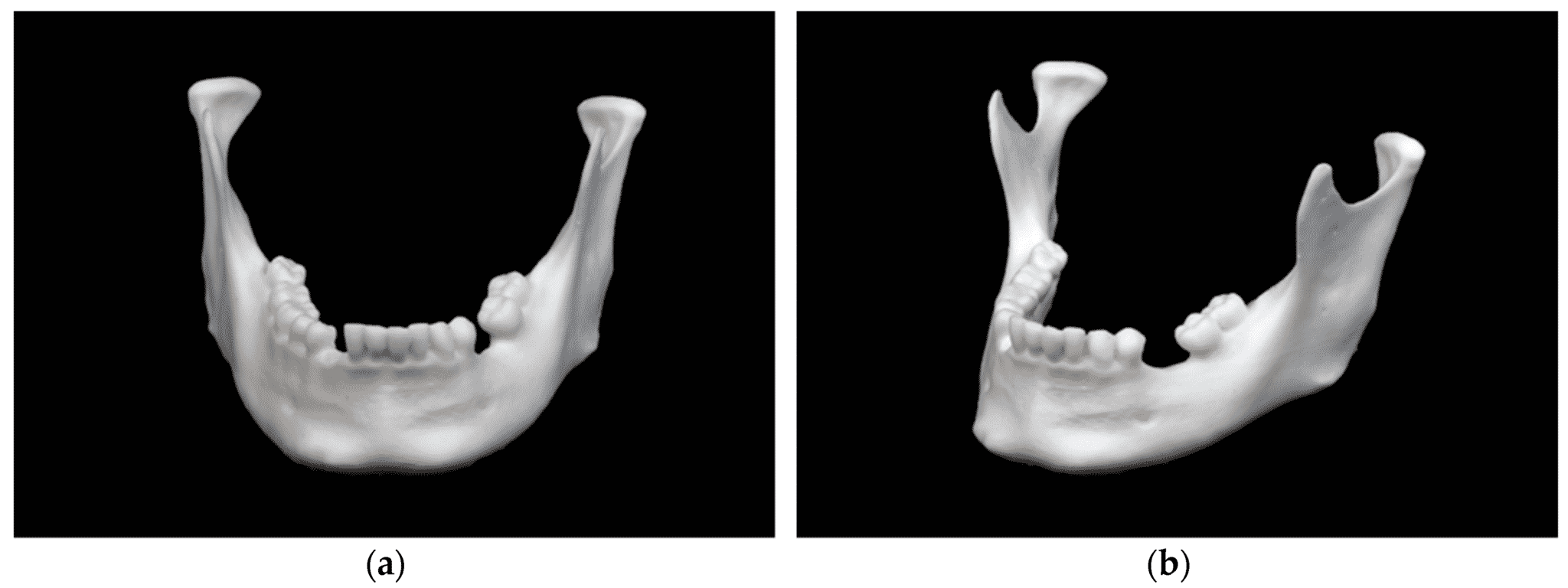

- SLS technologies –‘ssubtly coating lines’ have been exhibited, and also ramus markings were exhibited.

- Material-jetting 3D printing — Made matte and glossy surfaces, but ramus area markings were’observable’ no matter what.

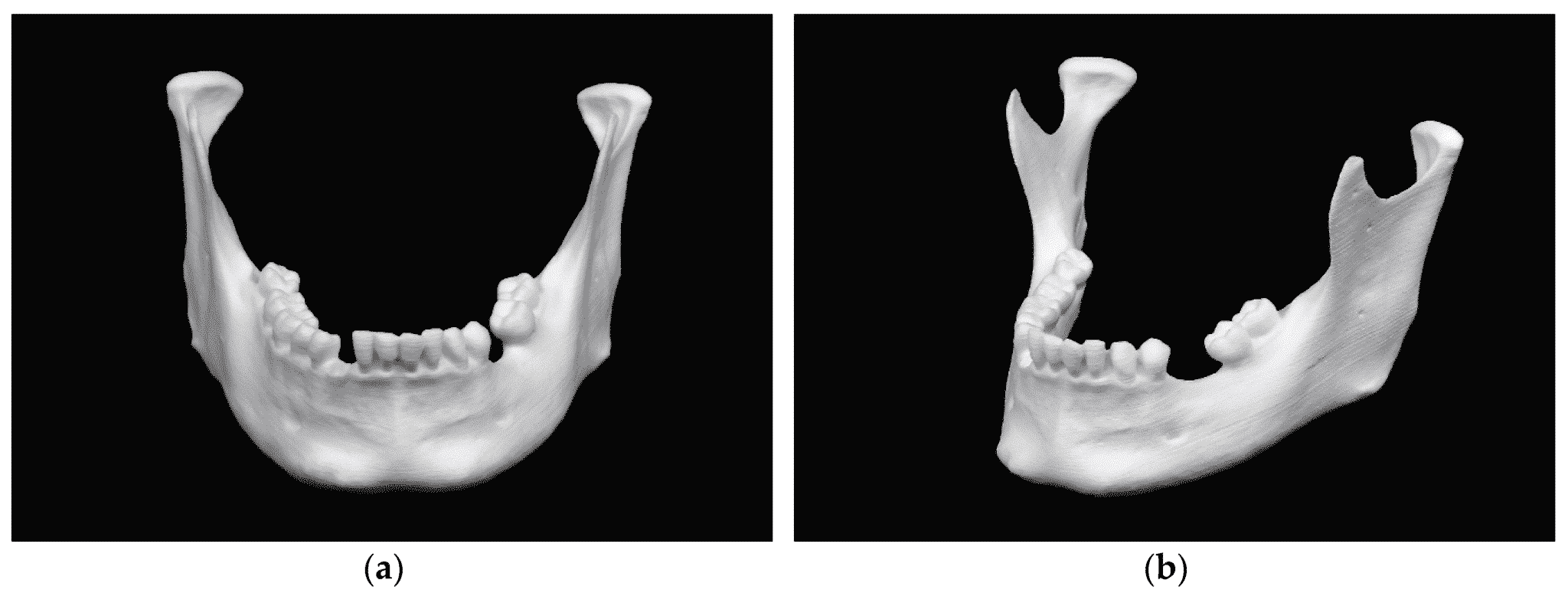

- Binder-jet 3D printing — Resulted in a coating. Ramus area markings were ‘not clear’.

“The findings here showed that all of the five evaluated printing technologies are very accurate. The SLS printer has the highest overall trueness (RMS 0.11 ± 0.016 mm), whereas the FFF printer has the highest overall precision (RMS 0.05 ± 0.005 mm). Despite the existing statistical significance of the differences in accuracy between all the 3D printers studied, when regarded separately, all are minor and acceptable for medical–surgical applications,” concluded the researchers.

“A broad range of cost-effective in-house desktop 3D printers based on simple AM technologies, e.g., FFF technology, offers both high accuracy and the ability to process a wide range of different printing materials, including a growing number of biocompatible materials. This qualifies them for most medical-surgical applications, such as the fabrication of anatomical models for the pre-bending of osteosynthesis plates, for surgical drilling and cutting guides, for implants, or simply for educational purposes.”