Direct machining of rubber parts without going through the lengthy steps of mold making and casting should be very useful for a number of applications especially when only small quantities are needed, when prototyping parts or for custom made single items. Just a few examples are rubber gaskets and custom-crafted rubber stamps. Probably there are many others. My interest is in prototyping small rubber parts for fluidics/microfluidics.

As you can find out by googling CNC machining rubber is quite tricky! Being soft, the rubber will normally just be pushed away by the tool or tear instead of the mill or cut when using a CNC milling bit. You could of course laser cut rubber with a sufficiently powerful laser, (probably not working with all rubbers!?) but I do not own one. I’d like to use my hobby CNC mill instead.

Buying or building an oscillating knife or swiveling knife accessory was also not an option for me, not only because of the complication and cost involved but also because these only allow to cut rubber, while I need a simple and cheap tool that in addition will allow me to also engrave and to drill tiny holes in the rubber.

I couldn’t find a solution until one day I thought: “Why not use a needle as a CNC milling bit? ”

After all, needles are very sharp and excellent in cutting and very cheap as well…which helps! A rotating needle at least should be able to cut holes in rubber and other “soft” sheets.

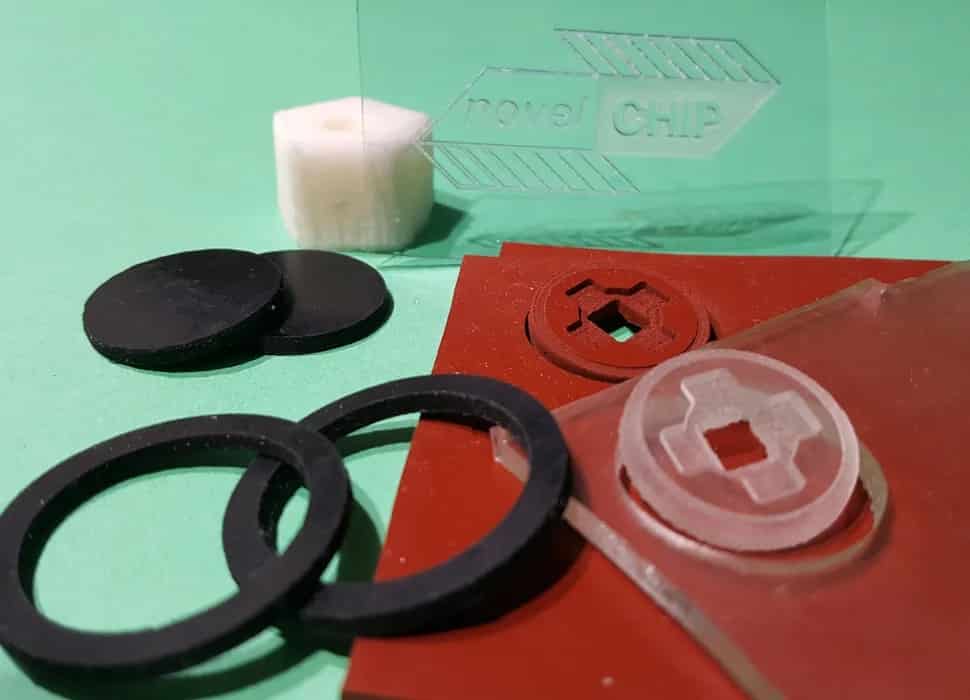

So I started buying a bunch of needles of different gauges at the pharmacy, mounted them on my CNC mill, and started experimenting with several types of rubber sheets and rubbery materials (silicone rubber, buna rubber, PVC rubber, etc…) getting immediately some great results! (and some failures as well).

So if you are interested in experimenting with a new, cheap, and easy CNC rubber drilling / cutting / milling / engraving technique, wait no longer and buy some needles and mount them onto your CNC spindle collet and start experimenting!

Here I show my experience (successes and failures) and how I solved some minor problems with mounting the needle on my spindle collet for very small needles.

Prepare: The Needle

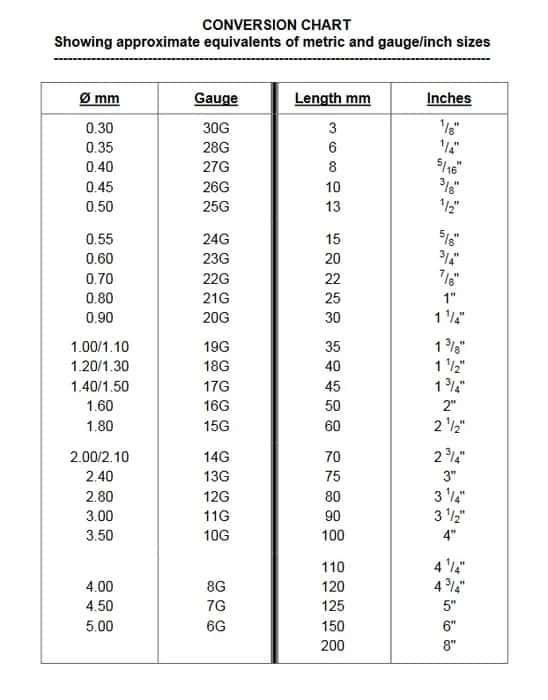

Needle sizes are normally expressed in gauges. A conversion chart to convert “needle gauge” into needle diameter (in mm) is the first thing you need to have a look at, to decide which needles to buy.

As my smallest spindle collet (Kress spindle) accepts only a 2 mm shank tool and no smaller, I started with a 14 gauge_Needle (2mm) which, although not common, can be bought in most pharmacies as it is used for infusion of patients.

Normal needles range from 18 gauge (1.2 mm diameter) to 25 gauge (0.5 mm diameter).

The only thing you have to do with the needles is to cut them to the length you like.

These needles might not be easy to fix on your spindle collet as it is not so common to have collets for such small shank diameter tools, unless it’s an adjustable collet such as in Dremels or you are well equipped.

If you are not happy with the bigger needles its time to consider building some simple adaptors.

Prepare: Make a Needle Adaptor

The simplest adaptor is obtained by sticking scotch tape around the needle to thicken the shaft until you can clamp it with your smallest spindle collet. Leaving a small “flag” helps to clamp the needle better in the collet: slide the “flag” into a slit in the collet. While not ideal, this adaptor still works reasonably well, since the forces on the needle are normally quite small because usually it cuts so well.

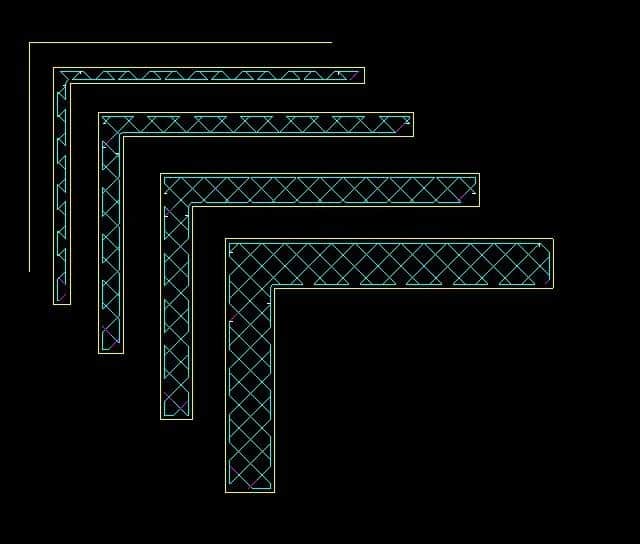

A more precise and versatile adaptor that requires however some effort in building consists in a metal rod with two holes: a first centered hole having a diameter slightly larger than the needle diameter (e.g. 0.02 mm larger) and a second off-center hole having the same diameter as the first hole but placed at a distance from the center equal to slightly less than the needle diameter (say 0.1 mm less). (see the scheme for a 18 gauge needle for an example). The depth of the holes depends on the needle diameter. The deeper the better but 6-10 times the needle diameter (a few mm) should be fine. The central hole serves to recieve the cutting needle, while the off-center hole to insert a short, blunt piece of the same needle (blunt it with sandpaper) used to firmly clamp the cutting needle. Once inserted the cutting needle, carefully push the short blunt needle into its hole using a small metal or plastic block, until it is completely inserted and holds the cutting needle firmly in place. The smallest needle for which I could build such an adaptor was a 25 gauge needle, using a 0.3mm endmill to mill the two small holes in a 8 mm diameter Brass rod.

Probably there are also simpler ways to build such adaptors. You might just try to glue a needle in a centered hole in a metal rod.

Prepare: Making Rubber Gaskets

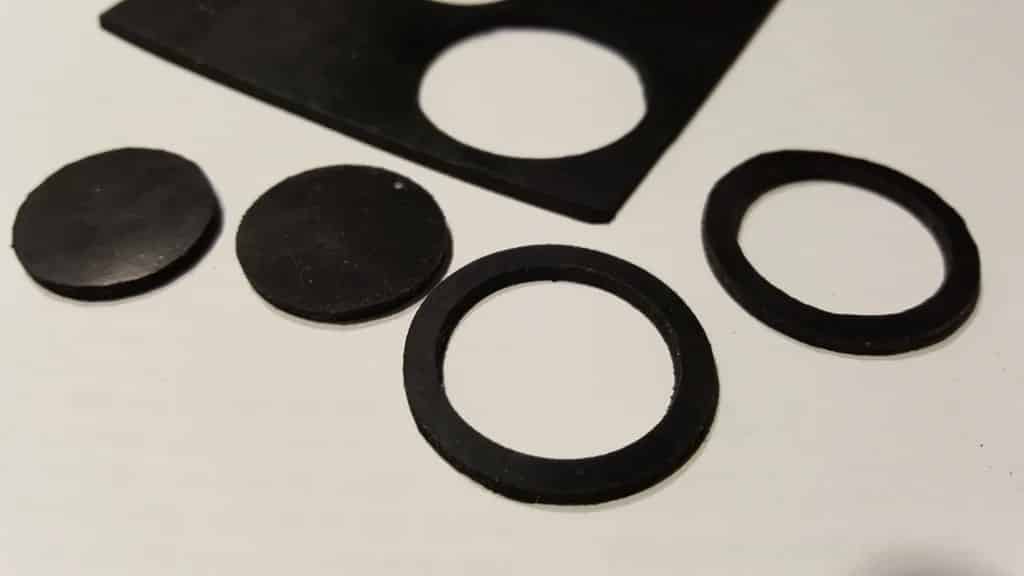

The most useful application for rubber milling/cutting is probably the making of gaskets. It happened to me several times that I needed a gasket of a specific size.

To CNC cut a gasket with a needle just stick a rubber sheet on a previously flattened working surface of your CNC machine (I used double adhesive tape) and start milling. I suggest you to start with a silicone rubber sheet since silicone appears to cut best with needles. You will then need to experiment with feedrate and spindle speed but usually higher spindle speeds and lower feedrates work better. I typically cut at feedrates of 200-400 mm/min setting spindle speed at 16000 rpm.

It also worked with black “buna rubber” however the needle wear out quite fast, lasting just for cutting a single gasket. Apparently buna rubber contains some abrasive particles and so I do not recommend it to be cut with a needle. Probably an abrasive grinding tool should be better in this case (for larger parts).

Case 1: Silicone Rubber CNC Machining

I got the best results with silicone rubber. For example transparent castable silicone (I used Sylgard 184 from Dow Corning or RTV 615 ) and commercial silicone rubber sheets.

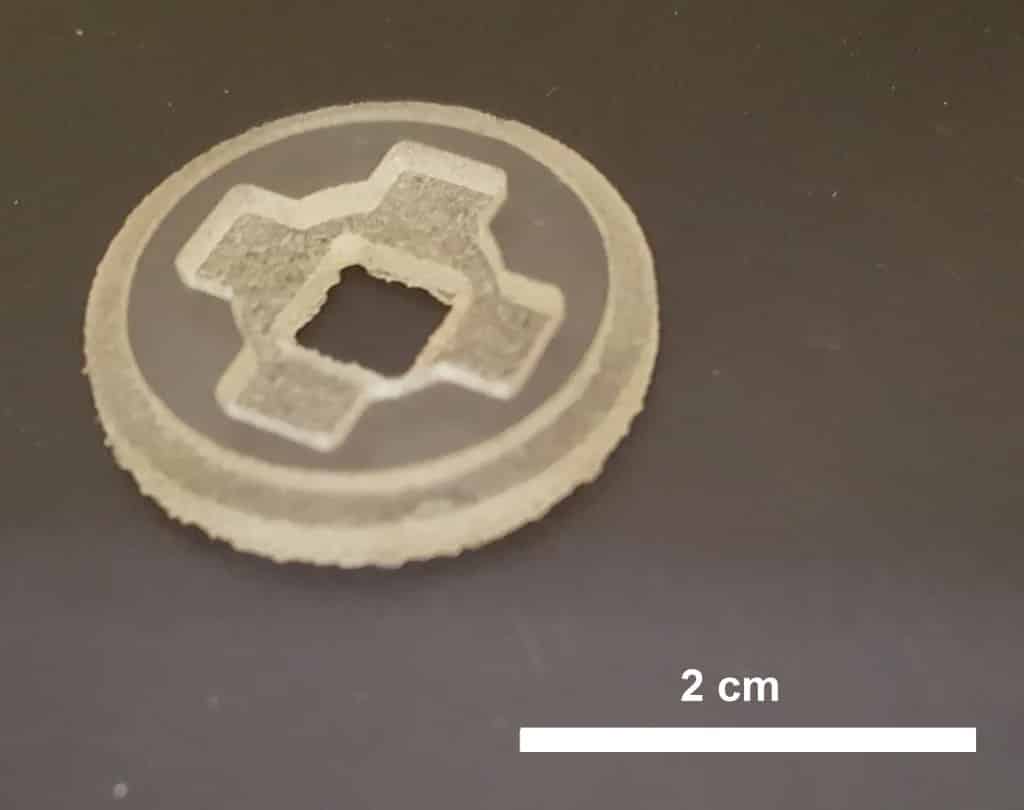

- To test the milling possibilities I milled a “rubber wheel” with some 3D structure, which turned out quite nice proving that rubber can indeed be milled with a needle.

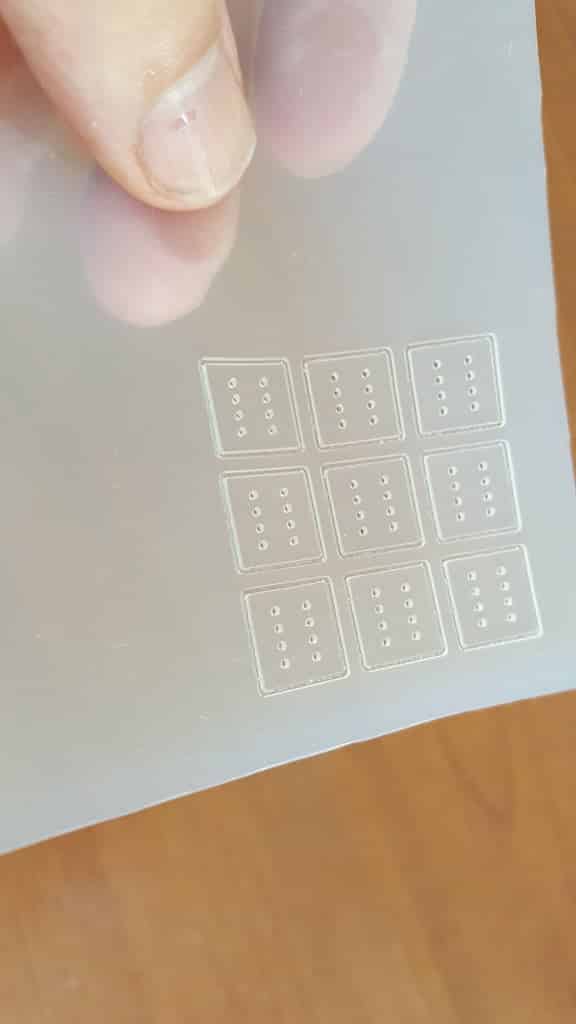

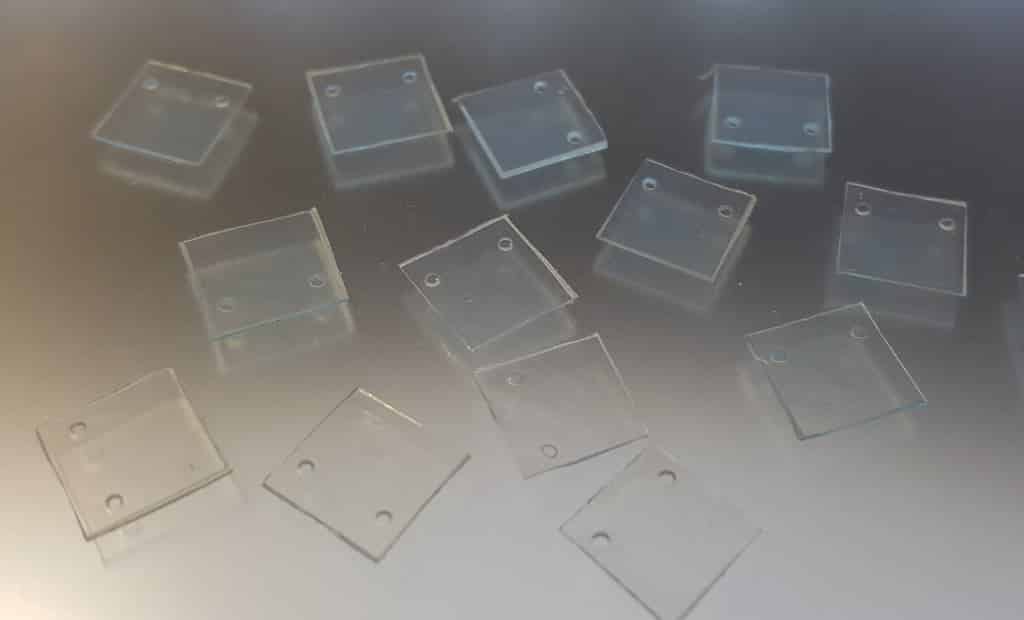

- Then I tested hole drilling, carving and cutting on thin commercial silicone sheets (0.3 mm and 1 mm). The results were also quite good.

At the moment I am using these capabilities to prepare membranes for fluidic microvalve, but of course they can be used for lots of other things.

Case 2: CNC Engraving Custom Rubber Stamps

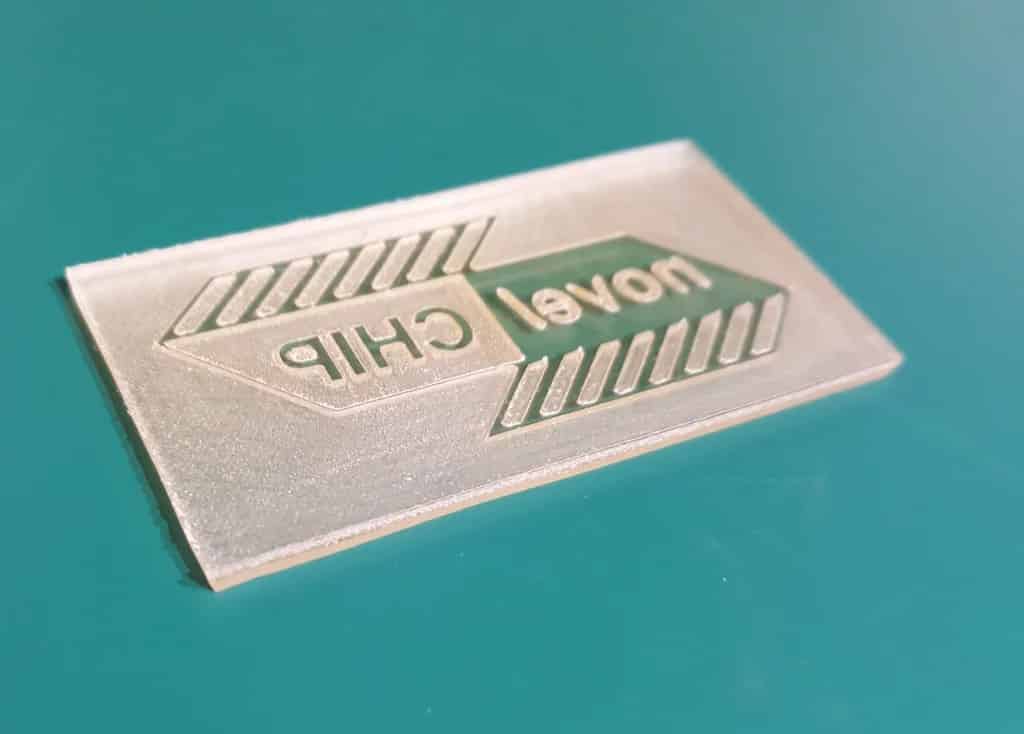

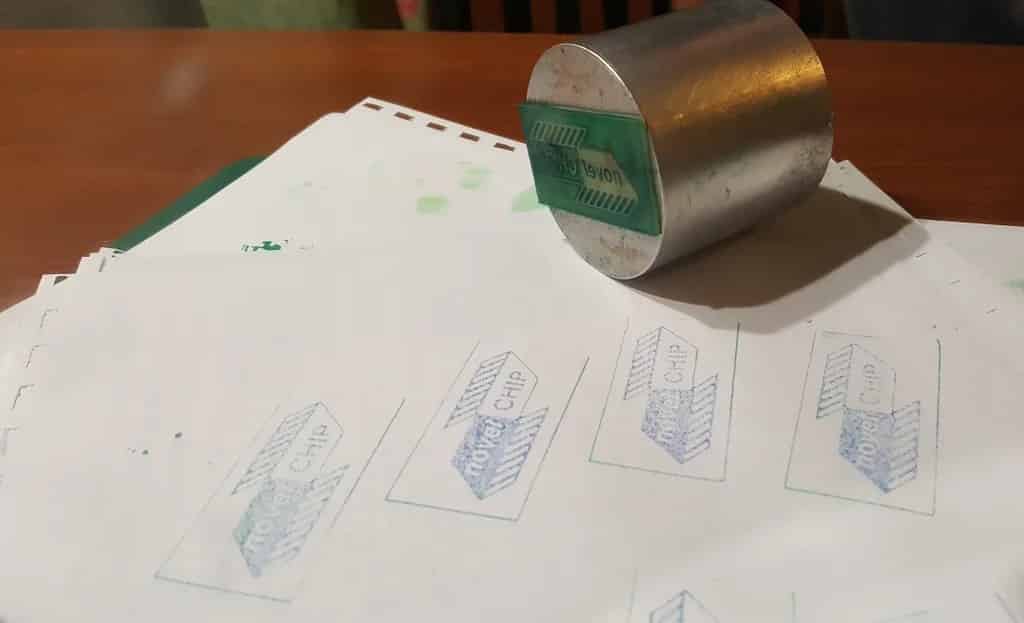

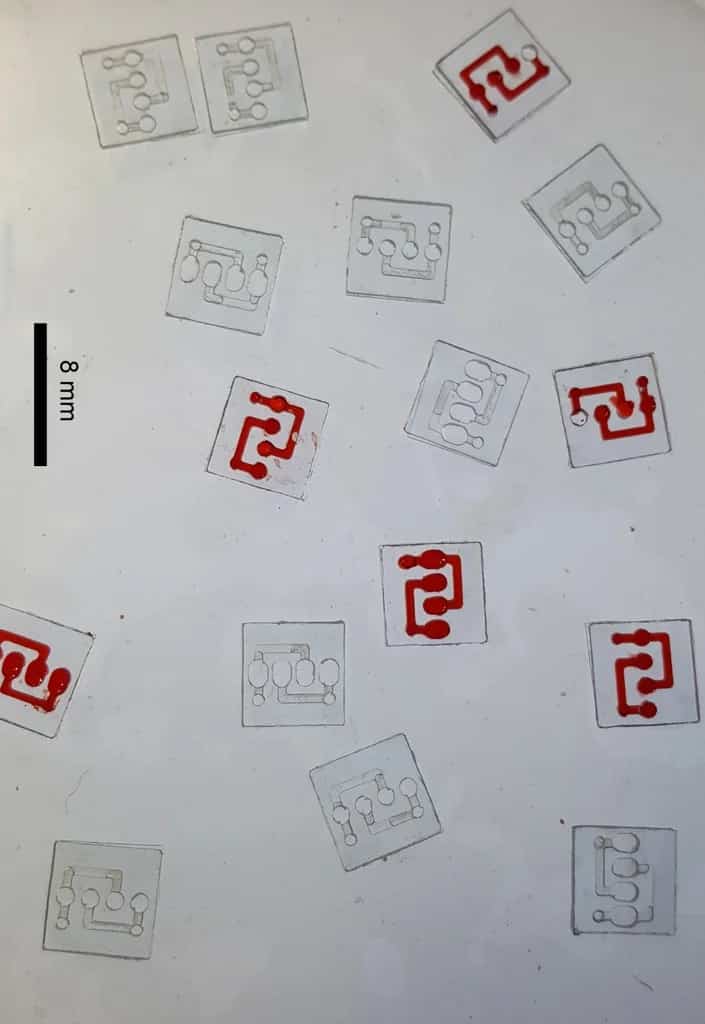

Another possibility is to use the needle tool to CNC mill custom rubber stamps. It turns out that quite nice rubber stamps with fine details can be made as you can see in the picture.

This is just to show the possibilities of rubber machining using a needle as CNC milling tool, so I didn’t search for any special rubber for stamping inks, but just used a PVC rubber sheet, 2 mm thick. Not sure if this is the best rubber for stamping ink. I milled my Logo 0.4 mm deep using a 0.8 mm diameter needle, taking care to design it mirrored in the CAD software, otherwise the stamped image will be mirrored!

For testing I glued the stamp with double-sided adhesive tape to a block and soaked a piece of cloth with ink used for fountain pens as an inkpad. Worked nicely!

Case 3: High Tech Applications: Microfluidic Devices

The reason why I started investigating rubber machining is my interest in fluidics, that is the technology to manipulate fluids (liquids, air) at small scales to perform different tasks. One application of fluidics is in biotechnology to analize biological samples rapidly and at low cost. The term “lab on a chip” has been coined to signify that biological analysis normally done in a hospital with bulky equipment can be shrunk down to credit card sized “microfluidic chips” that carry out the same tasks as big machines in laboratories, for example analyzing your blood or urine or even sequence your DNA. To rapidly get an idea what microfluidic chips can look like and what they do I think a good starting point is the LabChip youtube channel

For more detailed and updated information on what microfluidics is useful for, I suggest you to have a look at this technology update web channel

What I am specifically interested in is exploring the analogy between fluidics and electronics, since air and liquid can be used to make logic gates and computations as is done in computers with electrons (which also constitute a fluid- allthough an electrical one), by using valves instead of transistors. It turns out that it is quite easy to make such valves and fluid logic circuits even with very simple tools that everybody has at home.

I made some more complex fluidic circuits but still just by using my hobby CNC machine. This includes a Pulsing Fluidic Heart Micropump and Vacuum powered fluidic ink LEDs and circuits.

To progress however, I found that it would be useful to make these chips rapidly by direct CNC milling silicone rubber instead of rubber casting.

So I carved some channels and test patterns on thin commercial silicone rubber sheets (1 mm thick) first using a 0.8 mm diameter needle and then a 0.5 mm diameter needle in the attempt to make even finer channels.

Channels of widths around 0.6 mm and depths from 0.2 mm to 1mm are easily milled with the 0.8 mm needle. The reason why the channels turn out to be narrower than the needle is not entirely clear to me but it suits my needs of making smaller channels.

With the 0.5 mm (25 gauge) needle to my great astonishment I got channels that were so narrow that they could be barely seen by eye. I then understood I actually had made a “laser sharp” cut rather than engraved the silicone. So laser sharp cutting of silicone appears to be possible if the needle diameter is 0.5 mm or smaller and well centered. Again I do not understand why this happens, but it works and opens lots of possibilities.

To test some of the possibilities I designed a test pattern, defining channels in the CAD file as areas to be cut along the perimeter and inside using a crosshatch toolpath pattern to remove material inside the areas.

The results is shown in the picture and is absolutely incredible and unexpected! All those tiny channels could be made exactly as designed in the CAD with precise sizes and sharp edges and corners which would be absolutely impossible with any normal CNC milling tool, especially considering that I could mill these channels with any depth down to a few mm ! To better see the carved channels I have closed them with adhesive tape and then filled with red ink (food color dyes).