Hydrophilic-hydrophobic composite structures exist widely in nature, such as cell membranes, mammalian skin, and plant surfaces. The combination of this heterogeneous material allows cells to transmit bioelectrical signals and evolve complex life systems.

In recent years, the hydrogel/elastomer-based hydrophilic-hydrophobic structure has made significant progress and has extensive application prospects in stretchable electronics, software robots, friction generators, and other fields. But its structure is still relatively simple and cannot compete with the natural structure. As a rapid prototyping technology, 3D printing can be used for the preparation of complex soft structures. However, the interfacial adhesion performance of the existing hydrophilic/hydrophobic structures is extremely poor in the printing process.

In response to this problem, Tang Jingda, a teacher of the soft machine laboratory at the Academy of Aerospace, Xi’an Jiaotong University, and Suo Zhigang, the professor of Harvard University, have proposed a strong bonding technology for 3D printing of soft structures. They realized printing hydrogel/elastomer which has hydrophilic-hydrophobic structures and keeps an extremely strong interface bonding effect. Related research results were recently published in Advanced Functional Materials.

Difficulty in bonding hydrogel/elastomer composites

Soft materials have potential application value in modern medical fields such as biomedicine, electronic skin, and flexible robots. No wonder why soft materials are widely concerned.

As a kind of soft material, the hydrogel is composed of water molecules and polymer network, and gel with water as the dispersion medium. It has the advantages of high water content, the permeability of chemical biomolecules, biocompatibility, and biodegradability. The hydrophilic material is non-irritating to human tissues, so it is widely used in daily life, such as jelly (gelatin), baby diapers, contact lenses, etc.

Tang Jingda told China Science News, that the first generation of hydrogels was soft and brittle materials, so their mechanical properties have not obtained widespread attention.

In the past two decades, a lot of work has been carried out internationally to improve the mechanical properties of hydrogels, which has formed a research hotspot, and has successively developed high strength and high toughness such as nanocomposite hydrogels, dual network hydrogels, and tough hydrogels. Hydrogels, these high-strength hydrogels can withstand large deformations. Such as Suo Zhigang reported in Nature in 2012, a tough hydrogel named polyacrylamide-sodium alginate hydrogel.

Elastomers generally refer to materials that can be restored to their original shape after the removal of external forces. At present, elastomers are more widely known as polymers with elasticity. Elastomers have excellent mechanical properties and show stable properties under various environments. As a hydrophobic material, elastomers usually cooperate with multiple materials to form a hydrophilic-hydrophobic composite structure.

Hydrogel and elastomer have complementary properties. Therefore, designing a composite material with the advantages of both hydrogel and elastomer will greatly expand its application field.

In recent years, a series of hydrogel/elastomer composites are connected together by means of interfacial bonding, but there are disadvantages such as weak bonding force and uneven texture. Obtaining a homogeneous hydrogel/elastomer composite by a simple preparation method remains a major challenge.

Covalent bond & tough material for strong bonding

Tang Jingda said that to achieve the super-strong bonding of hydrogel and elastomer, two conditions need to be met: first, these materials are connected by a covalent bond; second, the hydrogel material is sufficiently tough. “In this way, the hydrogel/elastomer composite structure can achieve strong bonding.” Tang Jingda said.

Mao Yiqi, an associate professor at the Academic of Mechanical and Vehicle Engineering of Hunan University, said that he had tried to use a physical method to bond the hydrogel to the elastomer. “The hydrogel is wrapped with an elastomer, and they are bonded by water. However, the adhesive formed by this method is easy to detach and the effect is not good.”

According to reports, previously, Zhao Xuanhe’s team at the Massachusetts Institute of Technology took the lead in achieving hydrogel/elastomer bonding in the form of covalent bonds through surface treatment, but the surface treatment method is not suitable for 3D printing technology.

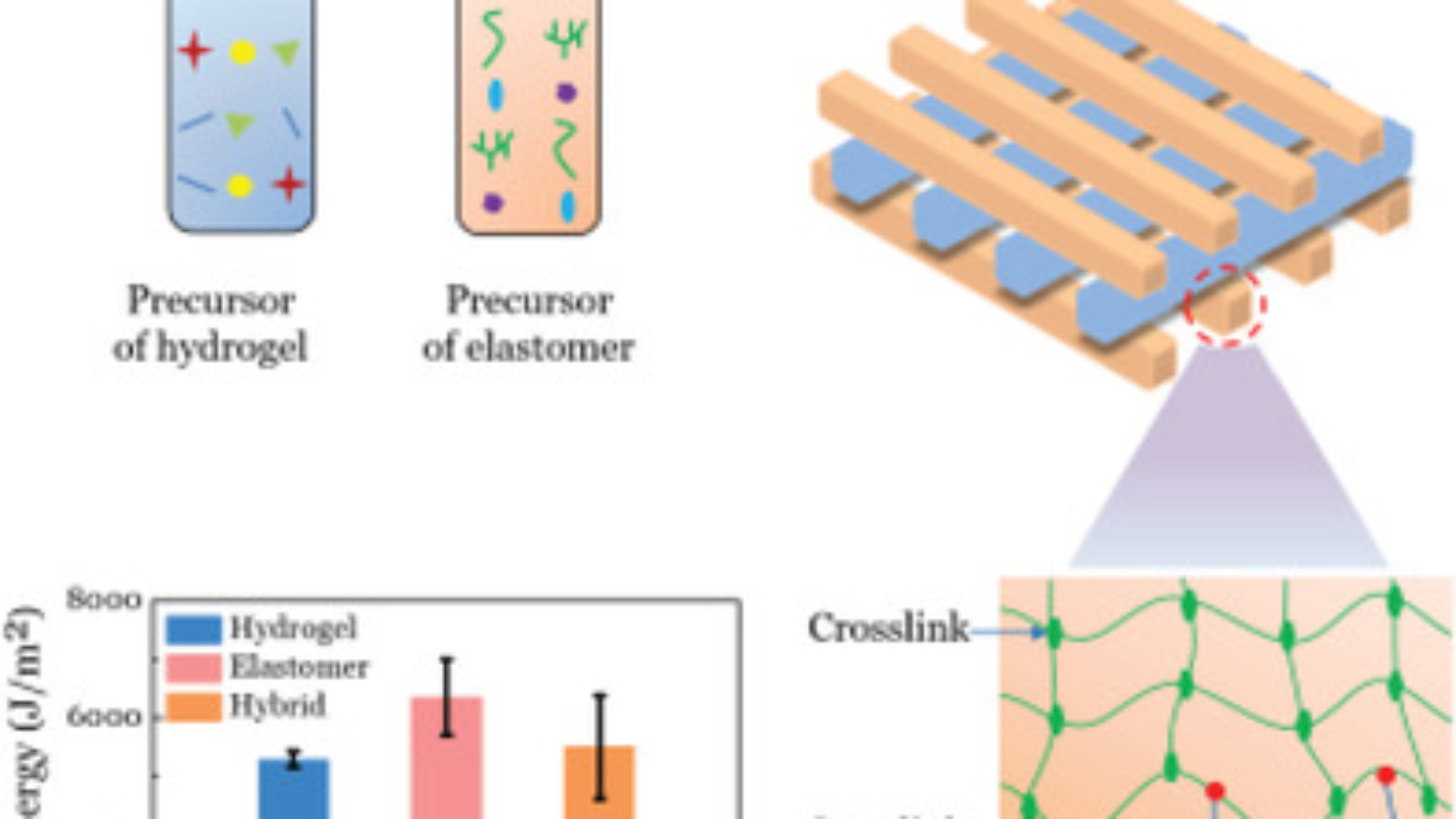

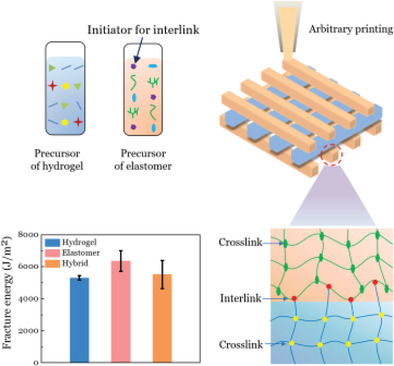

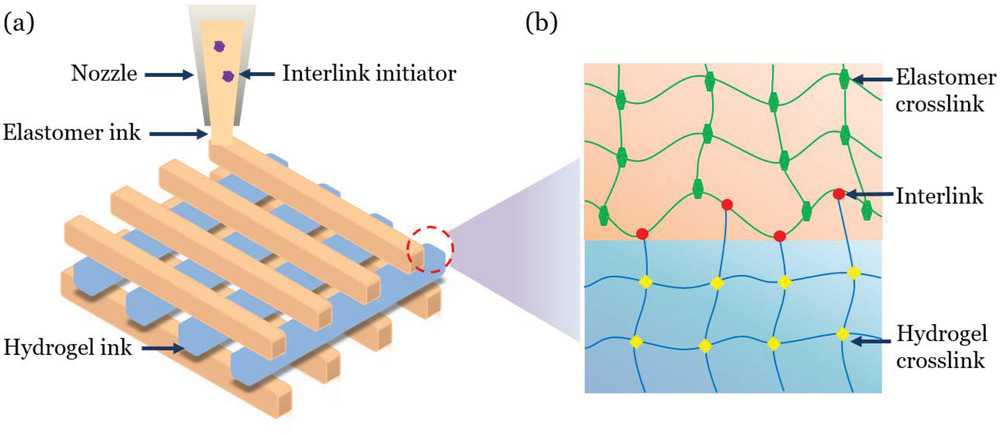

Tang Jingda et al. prepared the hydrogel and the elastomer prepolymer separately, and the bulk initiator was used to dissolve the coupling initiator in the elastomer material. Then adjust the viscosity of the elastomer prepolymer solution and the hydrogel prepolymer solution separately, print them together in any order, and UV-initiate the polymerization reaction, so that the hydrogel and the elastomer material are bonded during the printing process. Forms a hydrogel/elastomer composite with strong adhesion.

This method is different from the conventional surface modification but adopts the bulk modification strategy, and the adhesion energy of the printed sample can reach more than 5000J/m2.

To test the bonding effect, the researchers printed bonded and unbonded composite grid structures and compressed them. The bonded specimens did not break after undergoing huge compression, and the specimens without the bonding strategy could not bear at all. In addition, the researchers found that tensile fractures and swelling fractures occur when printing with normal gels. It can be seen that the formation of a stable hydrophilic and hydrophobic structure requires both good adhesion and a strong matrix material.

Due to the high water content, the adhesion of hydrogel to other soft materials is not very good. “This research uses an initiator to bond the hydrogel and the elastomer in the form of covalent bonds, which solidifies the bonding between the two and achieves a strong bonding effect. This is an interesting innovative technology. Mao Yiqi said.

Adhesive technology services are widely used in 3D printing

3D printing of soft materials is particularly widely used in medicine, which can print biomimetics such as the heart and blood vessels. Tang Jingda introduced for example that many medical students or interns did not have a complete understanding of the human body structure at the initial stage. Using 3D printed organ prosthetics, they could be trained and taught to help them form a more accurate sensory understanding. This will be of great benefit to their technical and skills improvement.

Mao Yiqi believes that the combination of hydrophilic and hydrophobic materials provides a universal solution for 3D printing of soft structures. This bonding technology is suitable for the strong bonding printing of a variety of hydrogels and elastomers and can be applied to a variety of applications. Such as the drive device for stretchable devices and functional devices.

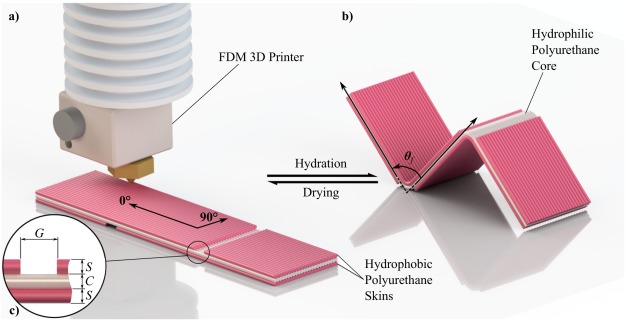

Tang Jingda said that the soft material 3D printing strong bonding technology is not limited to the application of hydrogel/elastomer bonding, and may also be extended to the bonding of shape memory polymers and hydrogels. Using smart materials such as shape memory polymers, 4D printing can be achieved with 3D printers.

“For example, when printing a planar structure, a stimulus (thermal or electrical stimulation) is given, and the plane can change from a two-dimensional structure to a three-dimensional structure. By analogy, a three-dimensional structure can also become another complex structure, which is called 4D printing. “Tang Jingda explained,” In other words, on the basis of 3D printing, plus the time factor, after giving the stimulation, smart materials can change from one shape to another shape to achieve 4D printing. ”

Compared with 3D printing, 4D printing is more intelligent. It can not only create new things with wisdom and adaptability but also change the traditional industrial printing. At the same time, 4D printing has higher requirements for printed materials.

Based on this, the researchers used this bonding technology to further print composite structures in the shape of flowers, butterflies, and octopuses to achieve 4D printing with the swelling response. “Therefore, this bonding technology will have greater development prospects in the field of 4D printing.” Tang Jingda said.

Leave A Comment