Boss Products, one of Australia’s most well-established building products manufacturers, has transitioned from traditional means of manufacturing processes to purchasing a customized Luyten 3D Platypus X2 printer and opening the country’s first 3D printing factory in the building and construction industry. The Boss Products building and construction 3D printing factory is located in Melbourne, and produces products for the industry across the commercial and domestic sectors. It is one of the biggest suppliers of planter boxes and retaining walls.

According to Michael Boss, CEO of Boss Products, the decision to transition to 3D printing was made about two years ago. “We could see the challenges ahead were going to be tough. As one of the leading manufacturers and suppliers of street furniture for parks and public outdoor spaces, planter boxes for commercial settings, and retaining walls for domestic and commercial use, we were continually having to find ways of making the manufacturing process more efficient but key elements including labor, power, and other operating costs were continuing to rise. We had to find another way.”

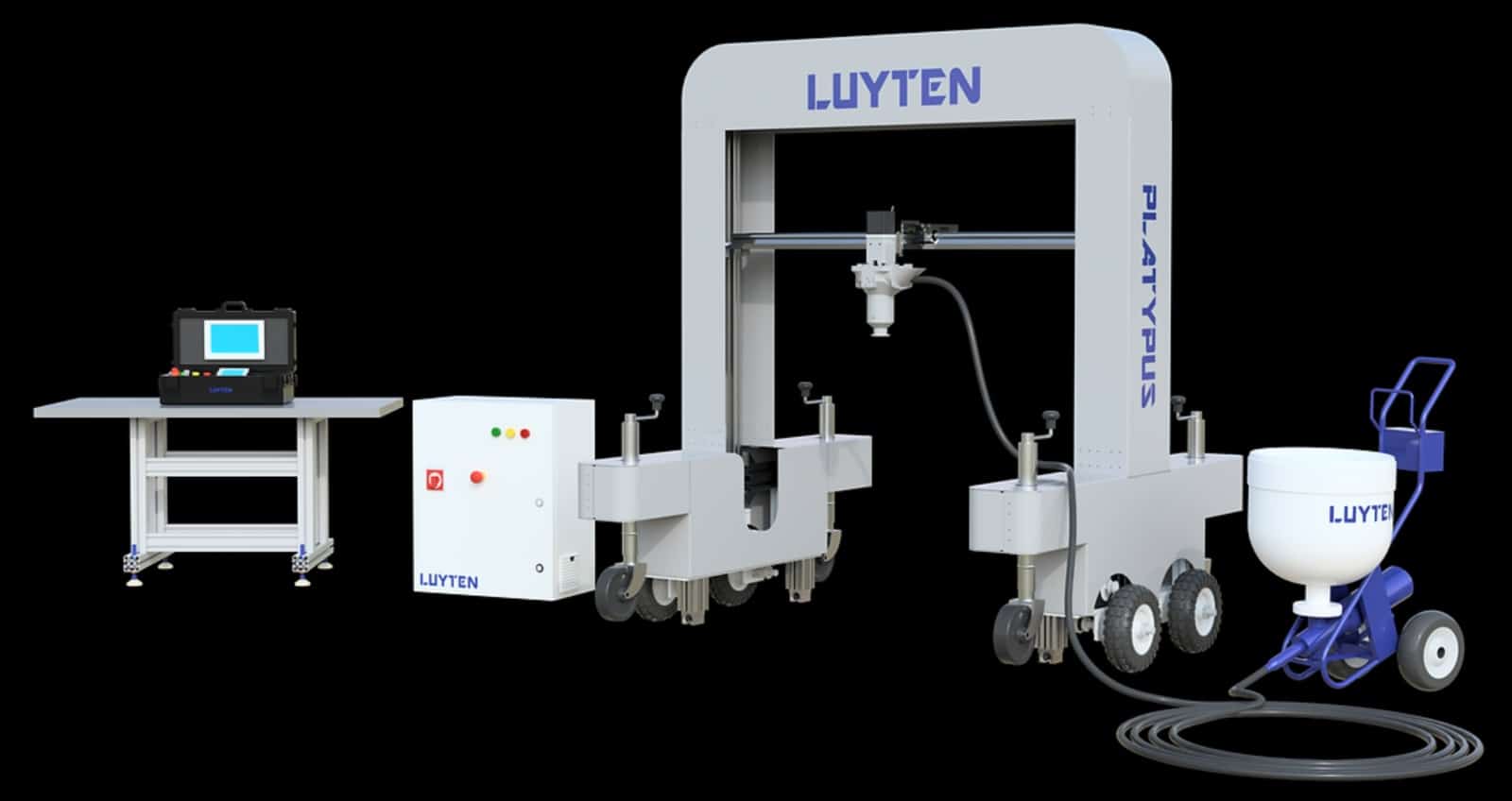

“We looked into 3D printing and realized that this was the answer. We searched the world for the most advanced and reliable 3D printing technology for building and construction and ended up finding the technology right here in Melbourne; Luyten 3D is the world’s best in its field. Companies all over the world are buying Luyten’s 3D printing technology and transforming their businesses, their customers, and their industries,” said Michael Boss. “We couldn’t believe how lucky we were to find the world’s best 3D printers for manufacturing and building and construction in the suburb next door. We purchased their Platypus X2 3D printer which they customized for us. It is a large machine with extraordinary capacity that is extremely easy to use and incredibly versatile.”

Luyten’s Platypus printer

Luyten’s Platypus printer

According to Boss, the traditional process of manufacturing a planter box, or a retaining wall, involves an order time of four to six weeks to allow for materials. During this time, the company builds the supporting structure for the mold, makes the mold, pours the concrete mix into the mold, and waits for the mold to dry. The actual manufacturing process takes up to 10 days in total. “The traditional process involves significant resources, labor, and other costs. It also takes a long time,” said Michael Boss.

“Using our new Platypus X2 3D printer, we are now able to print a planter box in a matter of 20 to 30 minutes. We have cut time, resources, and costs up to 95 percent. We are now literally able to manufacture at rate that is hundreds of times higher at a fraction of the cost,” he continued. “We are able to provide our clients with an unlimited number of designs and the flexibility to change the shape, size, or attributes of the planter boxes at the touch of a button. Using Luyten’s proprietary concrete mix, our planter boxes are six to eight times stronger than regular concrete.”

Michael Boss believes that he is now equipped to grow the business at an exponential rate and insulate the business against other issues impacting Australia’s manufacturing sector.

Manufacturing on Demand

“We are already looking at setting up a new factory close by to give us the increased production space to increase our printing capacity to produce over a million planter boxes and other products per year,” said Michael Boss. “We did our research and our homework has paid off. Our investment in 3D printing is already delivering significant returns.”

The entrance to one of Luyten’s 3D printed homes

The entrance to one of Luyten’s 3D printed homes

Founded in Melbourne, Victoria, Luyten 3D is one of the world’s most technically advanced 3D printer manufacturers for the building and construction industry. Luyten is one of the first 3D printing building and construction companies to build a 3D printed house in the southern hemisphere. It has also partnered with the University of New South Wales to progress the printing of structures and base camps on the moon.

“We are absolutely thrilled to see our technology being used right here in Australia. In fact, many businesses are starting to realize the unrivaled benefits of 3D printing,” said Ahmed Mahil, CEO of Luyten. “Our focus is to bridge the technological gap in large-scale and manufacturing industries through the introduction of robust construction automation technologies such as cutting-edge 3D printing and additive technologies.”

“We design and manufacture custom large-scale three-dimensional construction printers for domestic and commercial construction. In the case of houses, these can be printed in two days and assembled on day three. Printed elements are ready to handle and be moved within only five hours of being printed. This is the great thing about our special concrete mix, it cures quickly and delivers results that supersede what is currently available at four times less cost. In addition, the build cost 70 percent less in comparison to traditional methods,” said Ahmed Mahil

Since launching, Luyten’s mission has been to make construction easier and more sustainable across a broad range of industries by reducing the time and cost to build, the amount of construction waste generated, and the impact of build activities on the surrounding environment.

“Luyten transforms construction projects that traditionally take months or years to complete, and finishes them within a number of days. The 3D concrete printing revolutionary technology reduces 60 percent of construction waste, 70 percent of production time, and 80 percent of labor costs when comparing hands-on construction projects,” continued Ahmed Mahil. “In addition, the technology is proven to increase construction site efficiency with 60 percent guaranteed costs savings, 300 to 500 times shorter execution times, and an 80 percent total reduction in monetary expenses without formwork in concrete construction. The world has never seen capabilities like this before.”

“When forming Luyten, we were cognisant of the construction industry’s carbon footprint, and determined to create construction solutions for generations to come that reduce emissions. Our unmatched technology employs up to 40 percent less carbon dioxide emissions through propriety mixes that reduce use of cement, and the robotic systems reduce construction site and logistics carbon dioxide footprints by 50 to 70 percent,” concluded Ahmed Mahil.

You might also like:

Puredyne refines bioprinting process: Considering this, Puredyne has put needles at the top of its agenda – in order to further support the growing application area of bioprinting, and to find innovation potential.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment